First, some definitions so folks don’t get confused with my terminology…

Spring Switch - a switch through which a train may travel opposite the direction the switch is thrown, but whose points will return to their original position once the train passes.

Rubber Switch - a switch through which a train may travel opposite the direction the switch is thrown, but whose points remain in the new position.

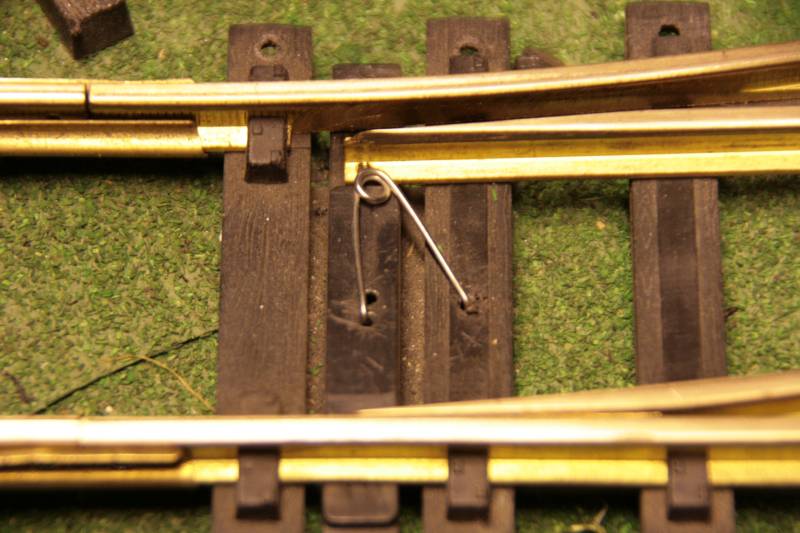

I use rubber throws (simple “V” springs as illustrated earlier) on all of my switches. I have a double reverse loop, so my trains will travel opposite directions around the loops each time they pass. It adds a great deal of visual interest, and it’s amazing how many folks ask me how I do that.

Here’s one thing to look out for. With a rubber switch, the first wheel that pushes the points over is the only wheel that needs to have sufficient weight to push the points. Once it’s through, the points hold fast against the other rail and the train can pass through just fine. Typically, you’re going to run into the most trouble with pilot wheels on steam locomotives, as they’re often rather light. Ideally you should have some sort of spring pushing down on the pilot assembly to give it sufficient weight. Relying solely on the weight of the truck and gravity isn’t reliable.

On a spring switch, the points always want to return to their original position, so they’re always pressing against all the wheels that are passing through the switch. This requires a little more thought as to the weight of the cars you’re running, as they all have to be heavy enough to move the points. Flat cars are notorious for being lightweight offenders and derailing on spring switches.

I’ve spent a great deal of time engineering front pilots to not derail on rubber or spring switches, as both my dad’s and my railroad make extensive use of these types of throws. The other half of the equation is the spring itself. It’s got to be loose enough to allow the cars to pass through, but rigid enough to where it holds the points firmly against the stock rails. That’s easier said than done in some cases.

Later,

K