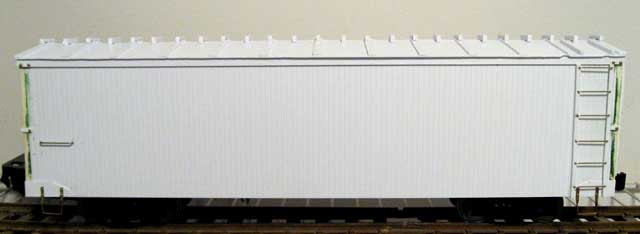

Last spring at York, both Bruce Chandler and I took trips to the PA RR Museum in Strassburg, and were intrigued by the composite boxcar they have on display. Bruce took a bunch of photographs of it.

The interesting things about this car are that it is still wood sheathed, but has metal ends and doors, and a steel frame (read: no pesky trussrods). It lives somewhere between wood cars, and steel cars (see Gary Buchanan’s beautiful EBT boxcar) It is a standard gauge car, but a good target for a “what if” for a narrow gauge car.

It doesn’t go with my Accucraft couplers.

It doesn’t go with my Accucraft couplers.