Many thanks Pete, I’m glad you noticed!

Hollywood, ever since you brought that up I’d been feeling guilty about all those little legs getting broken, so I finally had to do something.

Thanks Todd! I’m glad you like it, and I know you’d do an amazing job if you felt like doing something similar.

You only worried that some of them would sue you

Yeah, even those little 1:24 lawsuits really add up!!

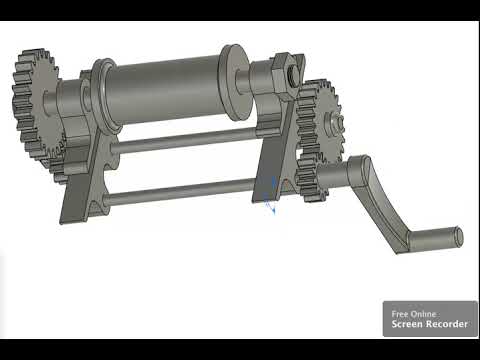

Shamespired  by Rick’s derrick, I’m pushing for some suggestion of a hoist. Here’s the design model:

by Rick’s derrick, I’m pushing for some suggestion of a hoist. Here’s the design model:

And here’s the parts.

Long way to go, but there’s a chance it’ll be done in time, we’ll see.

That looks mighty fine, Cliff. Looks very similar to one I made (printed) for my Mik back in 2019. Carry on

that would be very nice.

Sounds like a confirmation to me, thanks Dan!

Pic?

Cliff, mine was a single drum not a dual drum but below is a short video of the model. I’ll see if I can find a picture of the completed build.

Sweet!

Great model, Dan. Here’s the design model for the winch I did for the V&T derrick car #50. Single drum, two-speed.

What does the “purchase” term refer to?

Cliff, purchase refers to the number of spur gears which determines the speed of the crab. If you take the one above, your model of the V&T derrick, the two speed refers to a single purchase and a double purchase. The pinion gear that is engaged in your model operates the crab as a double purchase, high speed with a given effort and the opposite pinion will operate it as a single purchase, low speed with a given effort.

Probably can be explained better, but that is off the top of my head

Thanks for the explanation Dan. To put it in another way, the “purchase” number is that of the gear reduction steps?

See, I told you it could be explained better

When I think of purchase I have to think of it in terms of pulleys. But the concept is the same for gear purchase. A rope running up through a single pulley and to the load is a 1:1 purchase. It takes 100#s of effort to lift 100#s of load. Run that through two pullies pulling into each other and now the purchase is 2:1. It takes 50# of effort to lift 100#s of load.

When it comes to gears if the driving gear on crank handle is equal in diameter to the receiving gear on the drum (my terms I don’t know the correct names) then you have a 1:1 purchase. To lift 100# you need 100# cranking effort. If the gear on the crank handle is half the diameter of that on the drum then you have a 2:1 purchase.

The term purchase in this usage literally means purchase. You are “buying/purchasing” mechanical effort when you increase the purchase ratio.

However there is a trade off. In pulleys there is a directly inverse proportion in length of pull. In our same scenario with a 1:1 purchase if you want to lift the load 10 feet you need to pull 10 feet of rope. With a 2:1 purchase you will need to pull 20 feet of rope to lift the load 10 feet. With gears you have a similar inverse proportional relationship but instead of length of pull it the number of revolutions the crank must make to lift the load a desired distance. at 1:1 if it takes 1 crank to lift 10 inches then at 2:1 it will take 2 cranks to lift 10 inches.

when designing these things the engineer has to balance the gained effort with the increased inverse negative impact. The more you increase the purchase, while the power needed is reduced the duration of effort is increased. So determining efficiency across both variables is important. While it would be nice to lift 100# with two fingers it wouldn’t be very efficient because it would take all day to raise it the required height. By the same token if it takes three guys to lift the load the same height but they can do it in one pull that may not be as efficient as one guy doing the work but taken a little longer to do it.

I guess a lifetime on sail boats taught me something.

Thanks Devon, very clearly and completely explained. But, I think only you or Cliff would model that

Well!!! as a matter of fact when i built the crane car for the MIK I did factor in purchase. I had a 2:1 purchase for raising the boom and at one point I had a 4:1 purchase on the hook. I scrapped the 4:1 and went to a 1:1 for the final product.

Like Dan said, it’s the number of gearing stages, at least per this article. Each stage can have numerous ratios.

In a single purchase crab winch, a rope is fixed to the drum and is wound a few turns round it. The free end of the rope carries the load W. A large toothed wheel known as spur wheel is rigidly mounted on the load drum. Another small toothed wheel, called pinion, is geared with the spur wheel.

In a double purchase crab winch the velocity ratio is obtained in two stages. In this lifting machine there are two spur wheels of teeth T2and T4 and two pinions of teeth Tl and T3.

Thanks to the foregoing discussion, I now understand the winch I’m making is a dual single-purchase.

I (loosely) based its design from the same B&L catalog, which has this image for the same derrick’s winch.

I beefed it up though with side bearing castings. Here’s the current state of the parts.

After looking at the catalog image again, I’m thinking the pawls should be from brass strip, vs the clunky 3DP parts.

[Edit: I added the handles to the 3DP pawls, just to save some 1:24 fingers. I’m certain that many a 1:1 finger was lost while engaging or disengaging them!]

Onward and sideways,

Cliff