Todd Haskins said:

Such a neat build. Have you thought of making some of it a ruin possibly the sight of an ancient battle that was never repaired?

Thanks Todd.

I had thought about making it partially ruined. The problem is that at 30x40 it’s already pushing the boundaries of what will fit in the space available. One of the important considerations for me is to make sure that the layout doesn’t feel “crowded” since it’s supposed to be a village and countryside. And that prevents me from making things as big as I’d like. In fact, the motorcycle factory I made from a Piko Brewery is already way too big. But it’s a focal point on one end, so I’m mostly OK with it. And I’ve already had to scale back plans for a Rigi Duo and some oil wells, as it was just going to make things too busy for my taste.

Honestly, I thought that I wasn’t going to be able to fit the castle, but my wife had an idea for where it could fit (replacing another building). Anyway, it’s right at the edge of “too big” now, so I probably won’t add ruins on the outskirts. Though I agree that would be really neat.

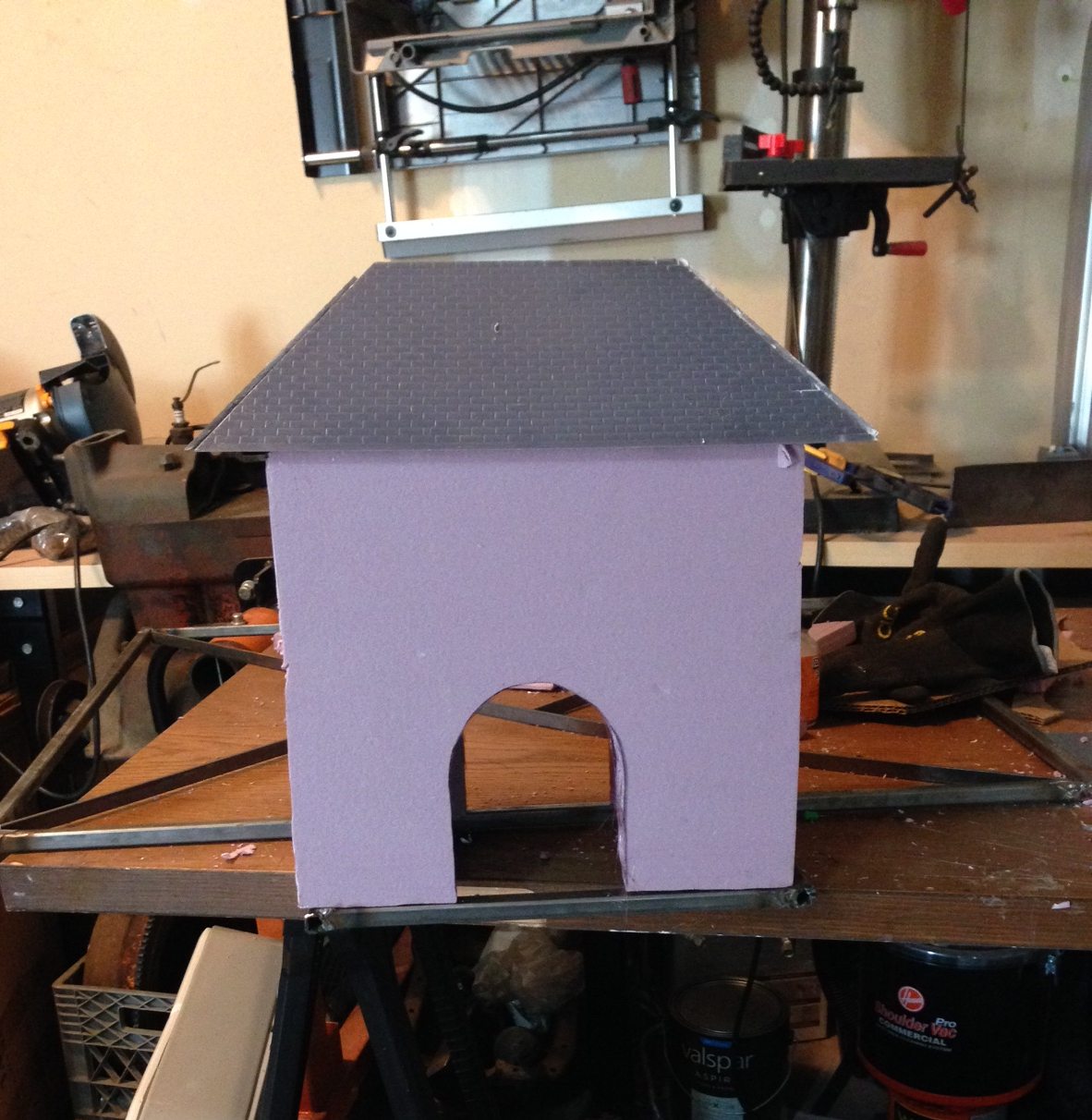

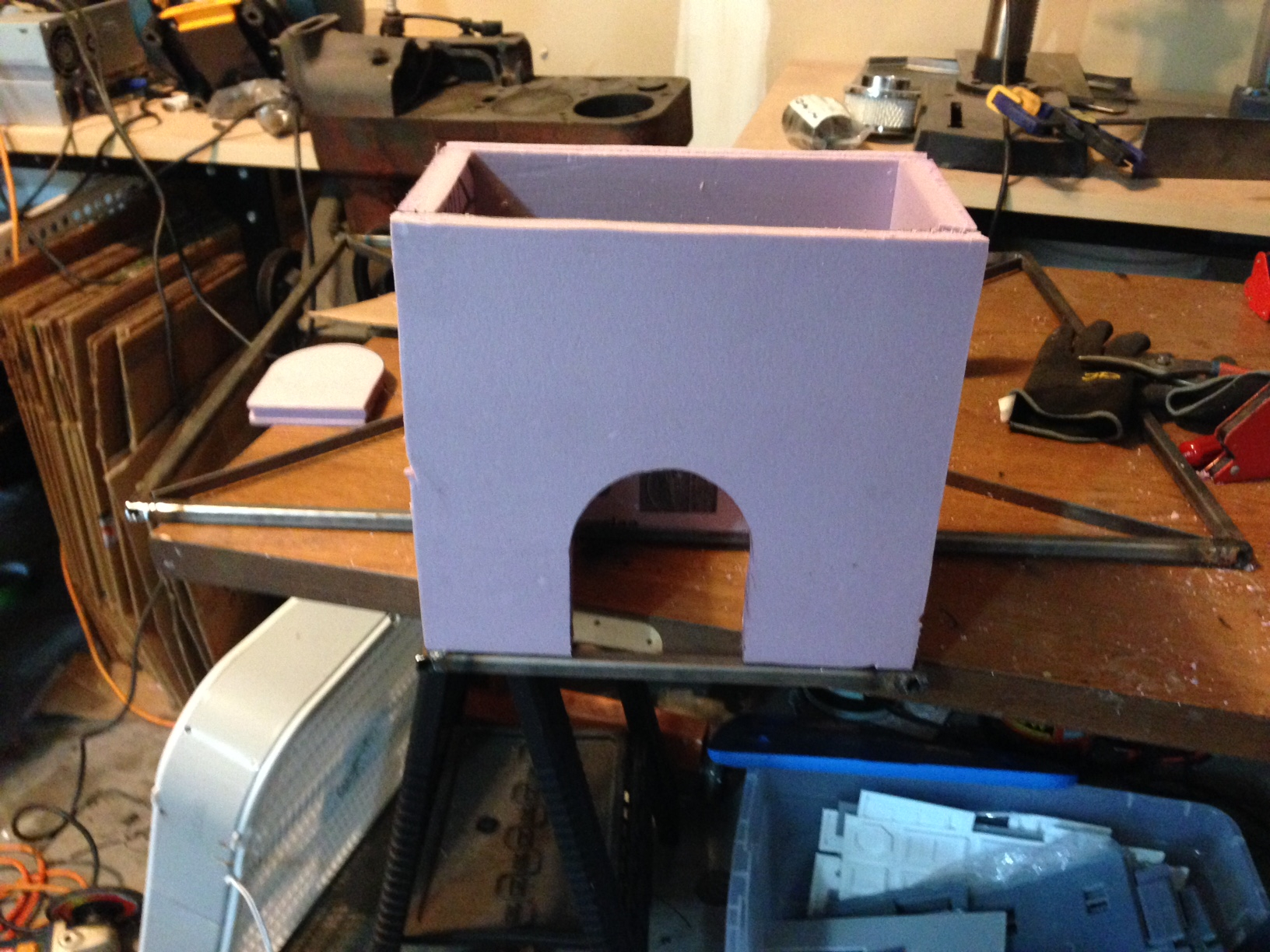

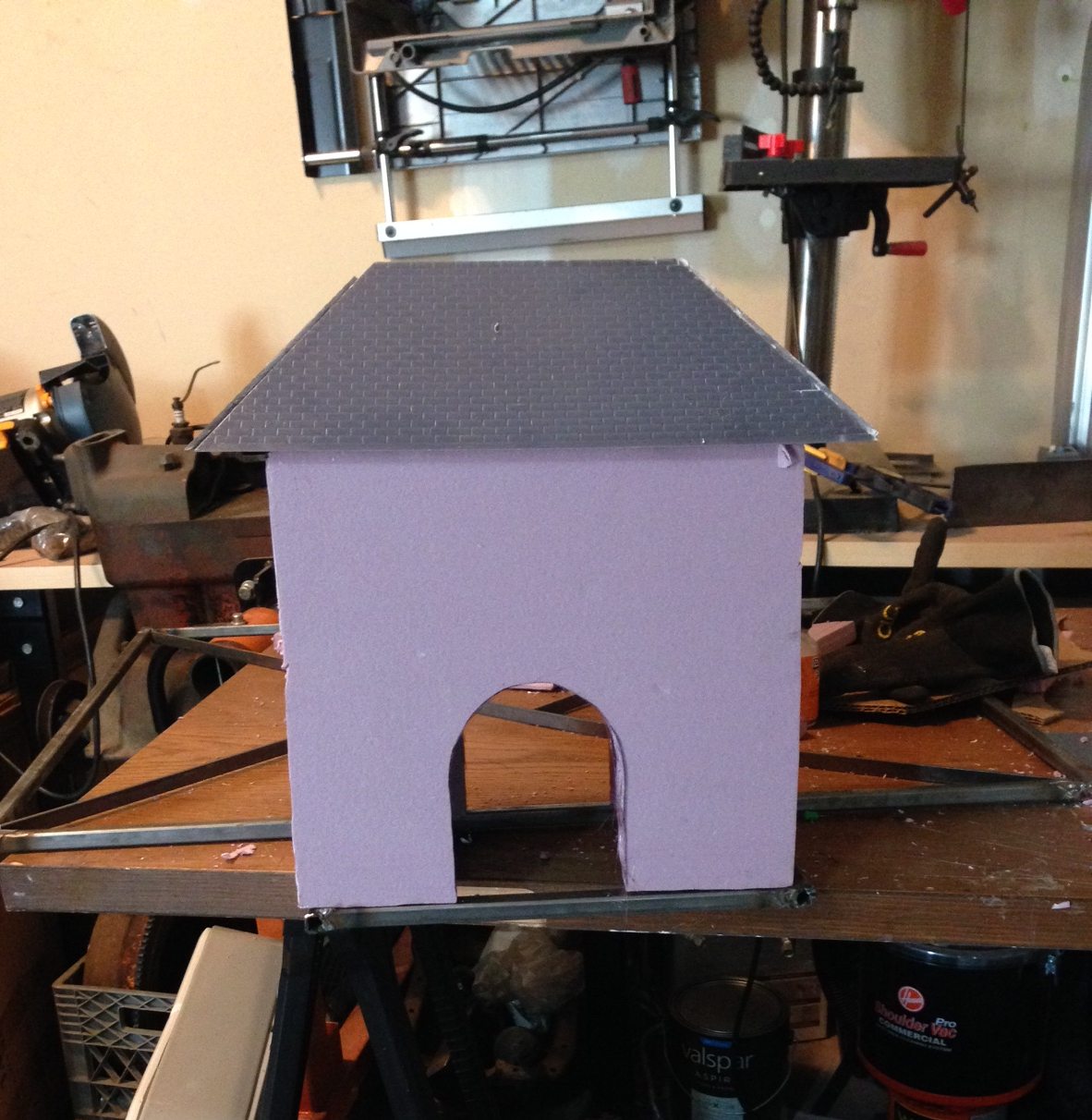

Here’s the gatehouse with the roof roughly in place: