Devon, why? you got the go ahead. So its all good.

Devon what are you waiting for a written invitation?

Get to work!

Sean, the expression around here is; “What? Do you need an engraved invitation?”

But Devon has done a lot of work, just not on the railroad. So when he has the open house, he can show off his concrete slabs. (http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)(http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

Yes this is true, I have not been doing nothing. I just haven’t been laying track. And I won’t be laying any for awhile. Still have to take care of some house keeping. Getting the power in and getting the siding done. That won’t look like railroad work but it all has to get done. But I hope it will get exciting soon.

David Maynard said:

Sean, the expression around here is; “What? Do you need an engraved invitation?”

But Devon has done a lot of work, just not on the railroad. So when he has the open house, he can show off his concrete slabs. (http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)(http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

and the siding and the electrical.

Ok the $%&#$ is getting real. I just sold my first born and ordered the track.

Devon Sinsley said:

Ok the $%&#$ is getting real. I just sold my first born and ordered the track.

what’s a first born going for? I’d like to sell my older brother off…(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-money-mouth.gif)

We’re all rootin’ for ya.

Yer bud,

John

Devon, your deadline is fast approaching, if you were outside with track in hand, vs. indoors typing you would be done!

Greg

Methinks Toby Keith needs another visit…(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Hey I haven’t been doing much typing. I have been working. But I have to admit I haven’t made much progress. I have spent a lot of money but I haven’t got much physically accomplished. I ended up getting a cold on Thursday. I have not had a cold since I had gastric bypass 3 years ago. I can only assume this is because I am physically healthier and also because I take radical doses of vitamins. Whatever the reason I don’t get sick. But this hit me like a load of bricks.

I ordered all the track and I have bought all the stuff I need to make the electrical runs. I started on that and have made the run from my garage to the corner of my house where the two runs will split. Its about a 50 foot run. All the wire and conduit is installed to there. But I think that maybe all the father I get. I have been pretty lethargic.

Yes Greg the deadline is fast approaching. July 2017 is right around the corner.

Devon Sinsley said:

…I ordered all the track and I have bought all the stuff I need to make the electrical runs…

What about the rail clamps? Track stops for the sidings? Switch stands?

David Maynard said:

Devon Sinsley said:

…I ordered all the track and I have bought all the stuff I need to make the electrical runs…

What about the rail clamps? Track stops for the sidings? Switch stands?

No, I haven’t got any of that yet. I got rail joiners but not clamps. That’s actually something I probably need to know about. I have heard much talk about clamps but when and where do I use them instead of just the joiners?

Track stops totally slipped my mind, add that to the list. Switch stands are something I am going to wait on until I actually get the switches. I really like the harp switch stands from Ozark but not sure if they are going to be rugged enough. I am open here to suggestions. Not sure even what I will have to work with on the LLagas turnouts. I might consider theirs as well. I want something very functional.

Devon I know you are a battery power guy, so rail-clamps may not be as critical to you as they are to us track power guys. But over the last 14 some odd years, around half of my rail-joiners have failed, either becoming so loose as to be worthless, or splitting open. Most failed within the first few years. I would say 3 to 5 years. Now I could have replaced the joiners with joiners, but I upgraded to clamps. The original Hillman’s clamps are doing just fine, but the later versions have also split on me. So now I am using split jaw clamps. The clamp holds the rails in alignment, and for us track power guys, they help the electrons go from one stick of rail to the next.

I should probably go rip out the remaining joiners on my railroad and replace them with clamps, to avoid any issues. But since they have been doing their job for 14 some odd years, and are still doing their job, I will leave them be.

When and where should they be used instead of joiners? Simple answer, everywhere. Clamps hold better then joiners, and good clamps (Split Jaw) don’t break with freeze thaw cycles like joiners can.

Don’t fool around with joiners. Get the Train-Li clamps. Nothing better. Also, go for the Bachmann switch stands. Look good, and are sturdy enough to stand up outside.

I happen to like the Aristo SS track screw joiners, but where I’ve cut the track or the rare stripped hole occurs then I’ll use a split jaw clamp.

Some folks think it’s best to leave gaps for expansion, but I butt every rail tight against the other and screw them tight. I do have weather here from 50s to 115 so there is some change. I noticed my curves bow more when it’s hot. I don’t have long straight a ways, so I’ve not experienced any kinks.

Without securing the rails together, it is possible for them to expand/contract in a concentrated area than a little in each joiner. That can be bad and cause derailments. Better to be fore warned.

Because I laid regular track over my trestles I used 3 stringers to allow for lateral slippage on the curves. It was a wise move.

John

Steve,

The Train Li clamps are listed for code 332 track. Not really having any idea how they fit is this going to be and issue for code 250 track? And if the height isn’t an issue are they sure to fit the llagas track?

Split Jaw makes code 250 in aluminum which will be for the right code and in aluminum means I wont have cathodic issues with dissimilar metals. They are made specifically for the Llagas foot print.

While its another 200-300 bucks for the split jaws, I think I can see where this is one of those do it right the first time things.

The Bachmann switch stands do look decent, not exactly the style I like, but in this case function has to come before form. I very much like Llagas’ but look like they would be fussy for operations. My favorite is the harp stand by Ozark but I am convinced they won’t hold up. I have one and love it and will use it on the indoor.

So far I like the Bachmann. One thing that needs to be is they need to be readily available like B mann.

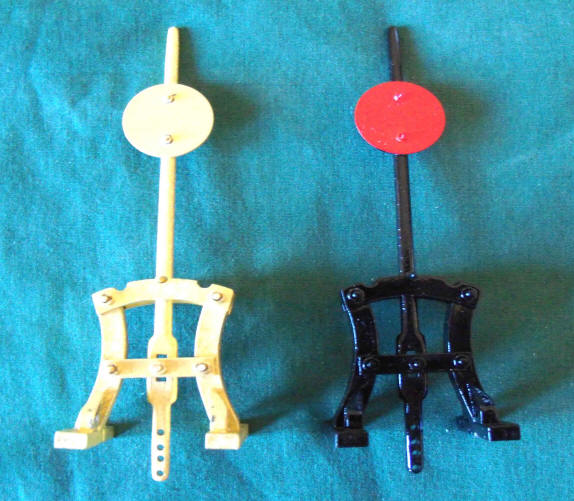

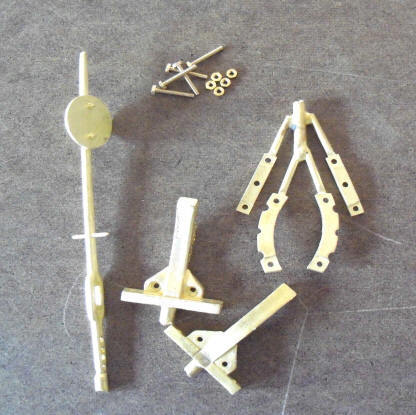

If your looking for a more robust harp stand try Phils Narrow Gauge. I have 5 or 6 on mine.

$25 for the kit. Sounds a bit pricey but I like the look.

What I like about them is they can be used on 3-way switches which is why I had originally bought them.

Devon, get the split jaws for your code and material.

Ken I do like those. Yeah they are a bit spendy but same as llagas and it a whole bunch more than the any others.

David I think the split jaw maybe the way to.go. I am not a fan of dissimilar metals in wet conditions. I have seen all to many times where different metals don’t play nice. Especially aluminum it gets eaten fast in the wrong conditions