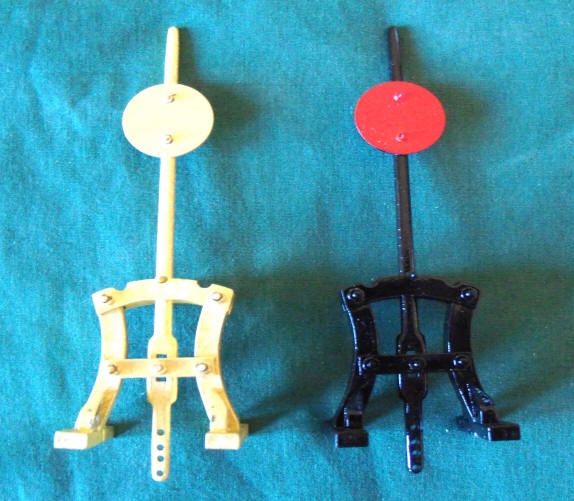

So as usual I have been agonizing and overthinking the switch that will lead into the yard. I am going to make basically a copy of Ken’s 5 way switch which is a homemade version of the one Greg showed me that I believe is a Tran Li switch.

Ken’s is 4 way but the one Greg showed me is 5. This is a pretty simply design but I have to obsess over it or it wouldn’t feel right. My only concern in making it was what to make it out of. You need a flat smooth surface that is weatherproof and can be screwed or spiked into and be able to use a router on. Since I am not there yet I have just sort of tossed ideas around but then I stumbled on a great product made in Spokane Valley that is a marine grade plywood that is surfaced in fiberglass. It is 3/4 thick stuff and has a layer of fiberglass over each side that has some sort of “paint” that makes the product waterproof. Best part is I got my piece free from a friend. But they do sell remnants. I will have to seal the cut edges and where I router the slot but that will be easy to do. It is smooth as silk also so the rails should slide on it with ease. I might start tinkering with that as a bit of a side project because I will need it done in order to lay the track in the yard.

I believe this is a statement I’ve seen on here before…

I believe this is a statement I’ve seen on here before…