That was/is quite a project!

Hi All:

Looks like a few people made it to the steamup despite the fires and smoke, we’re heading down there shortly. I adjusted the cameras as best I could last night while cleaning the shop, so there is a decent overall view from a couple of them…unfortunately, a couple are software zoomed and the focus is off so they are pixelated. I don’t know the IP addresses so I can’t fix it myself, maybe after I get there I can figure them out.

Staver Live with more overall view

Got the Laser moved into position in the machine shop and next week we can start work getting it hooked back up. Larry is happy to have it out of his office, although his office is bigger than the machine shop.

Here’s where it used to be…

And here is its new location…it will be better to work with in the machine shop for various reasons.

Here is a teaser of a new bridge I designed and built for Larry which I will discuss when I finsh the curved yard story.

Happy steaming, must get to Stavers and run a train and deliver some parts to some steamer friends.

Thanks

Karl

AKA Gearhead

Thanks a lot Karl.

Just keep it coming, wonderful.

I hope you dont mind that i basically copied your idea and i would like to do a own thread next year (you know time, it is running quick & a lot to do) with my “inventions” based upon your ideas.

Just keep it coming, track work, wood work, cars, bridges, heck and yes the tools you use, the info(how what and the name for more info) on the mill was very handy.

Fine details are very appreciated by me.

Why could you not do this in the Netherlands eu(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Probably i will skip the hammer proof pvc for frogs and make them from aluminium.

Have to invest in a mill and lathe anyway for making my own steam engines(thanks to Billy19?).

What i dont get, if you dont mind me asking:

You basically tackled everything incl gauge flange way gap tool for the frogs, a gauge for the frog to wing rail, wagon/car clearance ect.

Yes i took a good close look at your work, but:

Why did you not make some jigs/molds for pieces of track that will show up a lot of times like the strait pieces or a 3 4 5 or 6 meter or what ever in radii curve?

I can understand that the curves are not really standard and you must built in a transaction curve/piece(i hope you know what i mean) also.

It would save Jenna lot of time, instead of fiddling around with those magnets.

Just put the steel strip into the designated places---->weld---->next.

Probably also handy for rebuilding a piece of the layout, in my opinion, that is.

Sorry for the bold question i hope it was not inappropriate.

Glad that you and all that are over there are more or less oke, a house can be rebuild, furniture can be bought, memories stay, stay strong!

Btw, probably i read over it, but what do you use for your ballasting(if i use the right word)

Seems granite or similar around 2-3 mm in diameter?

Thanks in advance, Best Igor.

Hi Igor and everyone:

I haven’t had much time the last week, was very busy working with my buddy to build the infrastructure for the new laser location. Also, my dad lost his battle with cancer and passed last Wednesday, and I haven’t been in the mood to post. He almost made it to his goal of 90 years and having been on his pension longer than he worked…another two months would’ve done it. He had a good life, enjoyed his career, raised a good family, and for the most part, excellent health until recently. He passed quietly holding my sisters hand. We should all be so lucky.

Igor:

Larry found your posts on the Templot forum and showed them to me, you are vary industrious and I applaud your ingenuity making frogs and track with your available tools. A small bench top cnc mill would allow you to make frogs like we do in aluminum and would be a good investment and education for you. I have a Sherline cnc mill purchased 25 years ago to teach myself machining, and I still use it for engraving boiler serial number plates for my vertical and horizontal boiler production. Careful and patient watching of classified adds should lead to a deal sooner or later on a used one, or just by one new if you can afford it.

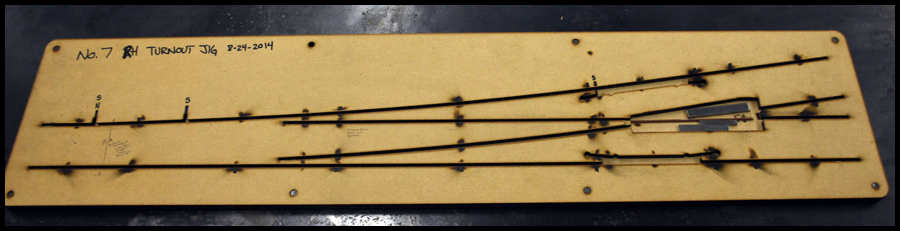

We do have jigs for #5 and #7 straight exit turnouts. Building the actual track we use 12ft (3.65 meters) lengths of steel strip. It actually goes very fast including building the transition curves. It is difficult to splice pre-built, or already built sections of track as described in previous posts, and storage of many sections of track would be difficult even in Larry’s large facility. Also, we never know what size or shape the railroad will be until a final plan is approved by Larry, so we could easily end up with much unused sections of track. Most of the turnouts are built in networks, again because splicing them is more time consuming than building them together. Even a straight yard ladder using number 7’s from our jig would go faster if we build most or all of them at once on the welding table instead, than trying to splice many individual turnouts…this may seem counter intuitive, but believe me, after building track for over 6 years now, I know what works best for us.

That being said, there are many times when having a bunch of pre-built turnouts is very helpful, such as installing crossovers, or the diamond crossovers, or just turnouts for sidings and passing tracks, so the jigs allow Jenn to quickly build many them, and have proven very reliable after building dozens of turnouts.

My jig design is simple, just two pieces of 1/4" MDF, laser cut with tight tolerance to our rail width. One piece is simply a base board with pin holes for dowel pins to locate the second piece…obvious in these pictures.

We have right and left hand jigs for both sizes, and we can easily laser cut a different size if the need arises. Jenn simply pre-cuts many lengths of rail, then rolls the curve until they drop right into place without tension, the parts in the frog location are used to align the frog with the rails so it is not skewed, then she welds braces which have also been pre-made in bulk at the sizes needed. This system has worked great for years.

I must go to Stavers and finish the air drops for the machine shop, but here is couple pictures I promised to post of what it looks like outside since tearing out the outdoor loop.

First, a reminder of how it used to look…

After Larry Larry and his sons have done some demolition and excavating.

The terrible smoke and air quality conditions are apparent in the recent picture…where are the hills?

Off to Stavers

Thanks

Karl

AKA Gearhead

Hi everyone:

Sorry I haven’t been posting, life and obligations have caught up with me for awhile. Been meaning too, but each day seems to bring new obligations. The laser install went smooth we thought, but it wouldn’t fire because of a coolant issue, we tested all appropriate systems and came to the conclusion that something in the laser itself had reduced the flow of coolant and caused an alarm. The laser company recommended running a mild bleach solution through all the systems followed by a flush to remove any algae or scale build up…well, that caused two power supply, and the RF generator heat exchangers to fail and spew coolant everywhere, so now we have a new set of problems to solve. Fortunately, no electronics or high powered circuits were destroyed since testing was performed with the breakers off to the laser itself. Quite annoying, since we didn’t have any issues moving the machine and it rolled quite smoothly into its new location. Oh well.

Many personal issues too, such as many carburetors and ignitions to build all of a sudden(Covid 19 seems to have made everyone enter the garage and work on their hot rods), and I must deal with my dads home and estate. I also had a birthday and regular job interview because Jenn and I want to move to a home with a shop, and getting a loan as a self employed contractor is nearly impossible.

Anyway…tomorrow (Oct., 10th, 2020) starts a small 2 day steamup event to allow the Seattle guys to come down and run, and give them enough time to make it worth the drive. Probably no more than 12-14 people all taking Covid precautions. I will try to make sure the Live @ Staver cameras that are working, are pointed to interesting views of the activities.

I will get back to answering previously asked questions and promised follow ups as soon as things settle down a bit, probably in a week or so.

Thanks

Karl