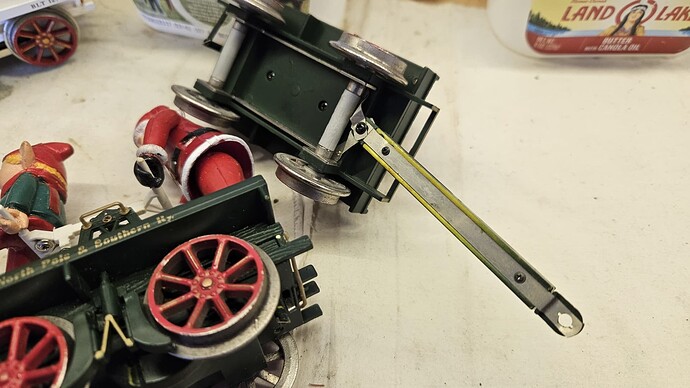

This is the motor from a Christmas Gandy Dancer with 2 trailers. I have 4 of them in pieces, and most have cracked gears and broken studs for screws. I did find one chassis with ‘good’ gears.

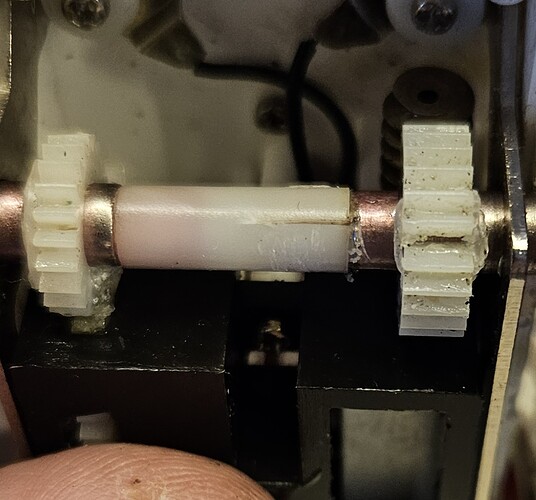

Now I need to find a good motor! One smokes as it spins from the commutator, and the other one (pictured) spins but the brushes get very hot.

Am I right in thinking that things get hot when they have electrical resistance?

I think I am going to have to take the brushes out and clean everything. Unless someone has a better idea?

so you make your own decision.

so you make your own decision.