Rick Marty said:

Very cool stuff Gary, your ability using those programs astounds me. Just out of curiosity how does riding behind that locomotive work out with that trolley poll sticking back in your face?

Rick,

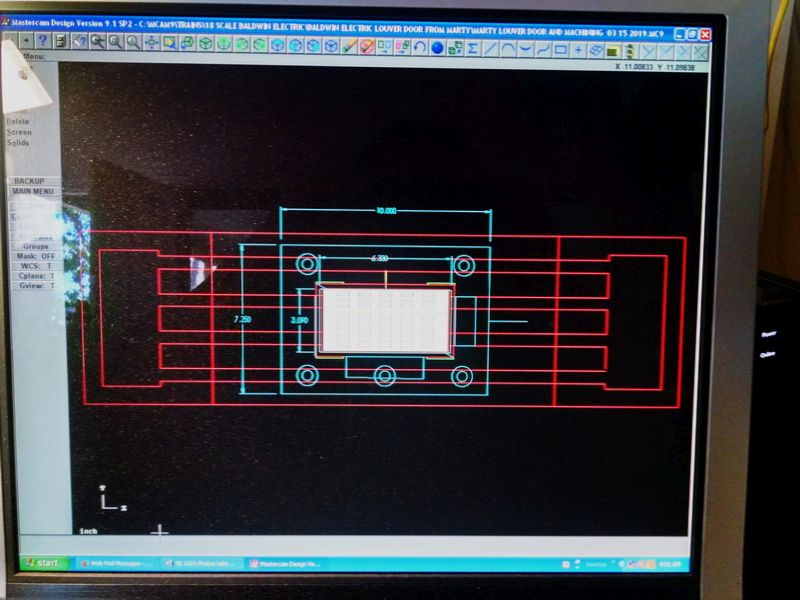

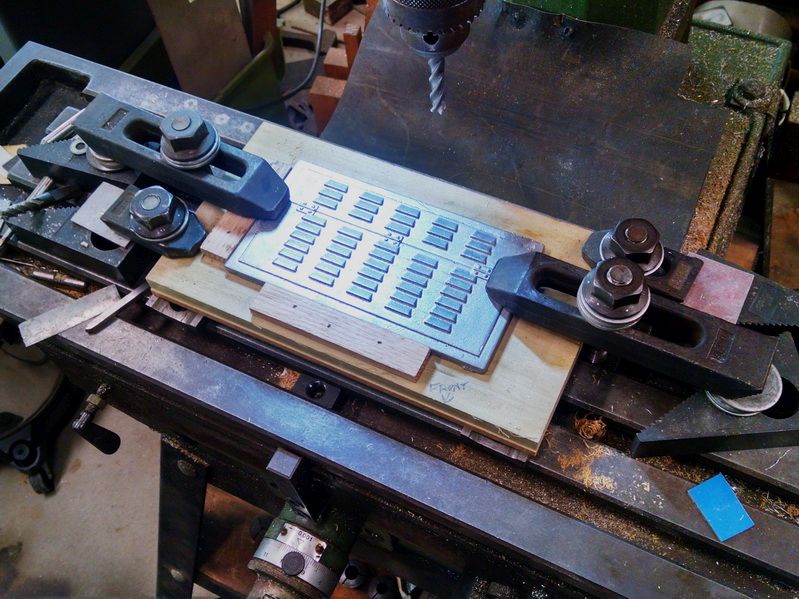

I have been using MasterCam since about 1992 or 1993. The last die shop I worked for before my retirement wanted to get into NC milling of forging dies. So the owner and I decided we needed to learn the software so when he purchased a new Haas horizontal CNC mill ($150K+ investment), we had no choice but to take the risk and get it done. Lots of head scratching for a year or so, lots of frustration during the learning curve (lost some money along the way. But eventually everything “clicked” and we were on our way. Never looked back. I have been convinced to try Fusion 360 from a number of folks on the Chaski (Home Machinist website) and quite a few vendors that sell detail 3D printed parts for the ride-on scales. The Fair Weather Foundry back in Kent, Ohio is owned by a guy named Marty Pinkston. He started using 360 a few years ago to make molds for detail parts in 1" and 1.5" scale stuff. He was the one that cast our louvered doors for these Baldwin engines using ONLY a photo I provided of the prototype. The technology just “begs” to be used now. And because the software is free to hobbyists, you really can’t pass it up. I actually needed BOTH software products to get what I showed in the previous post. I am faster in drawing in MasterCam than 360. And I can surface a part faster in MC. But 360 gives me the ability to get the files converted to a format that Shapeways or any other 3D vendor can use. They are all just “tools” and I use what I feel most comfortable with. &5 is “probably” a little late to be learning this stuff, but it does keep the “gray matter” from decomposing!

As far as the trolley pole getting in your face when running these engines, the fact of the matter is that the trolley wheel on the end of the pole sits just above the center of the rear coupler. Never gets in the way. The total length of the finished pole is a little over 26 inches. Take a look at the first photo of the prototype #1624 engine and you can see that it falls short of the end of the locomotive. So that is not an issue.

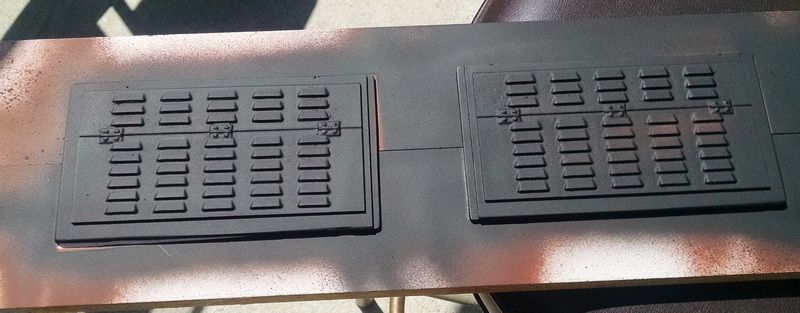

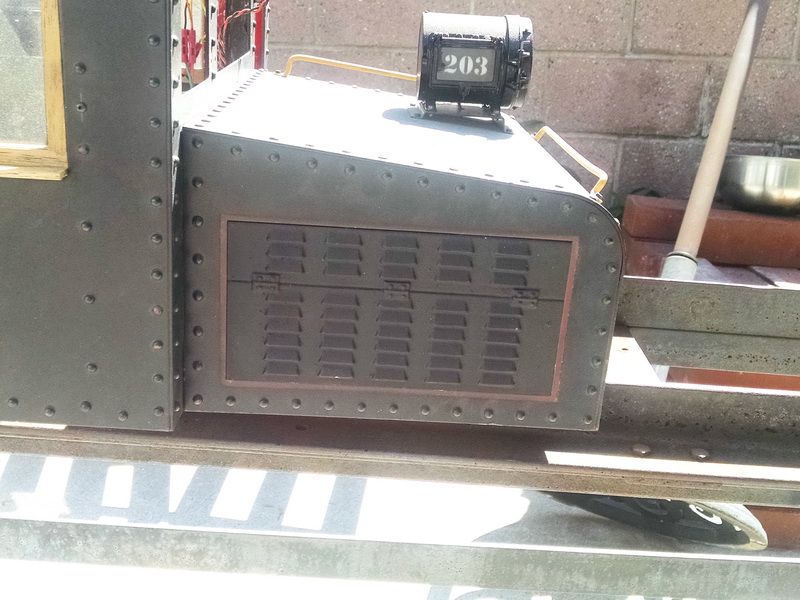

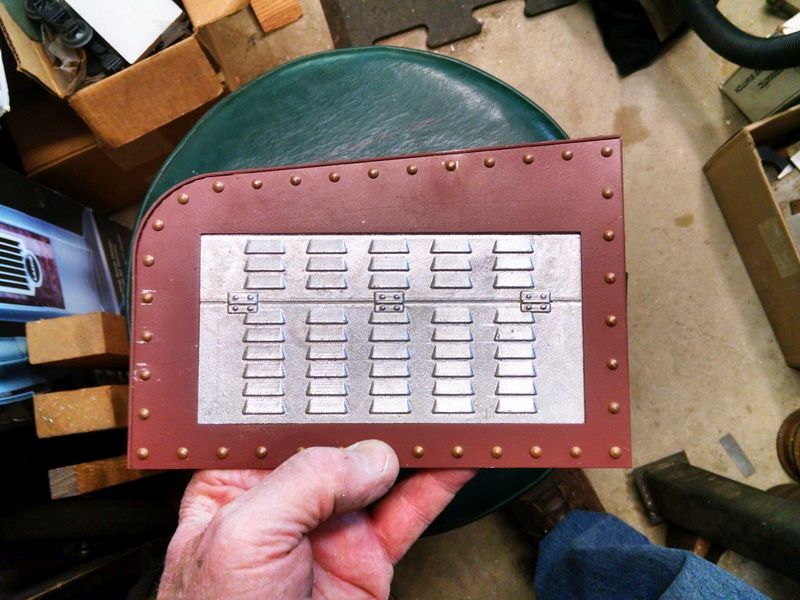

). A couple of photos taken today and the last one, shows one of the lover door panels install on my old Baldwin electric.

). A couple of photos taken today and the last one, shows one of the lover door panels install on my old Baldwin electric.