Well, a few months have gone by and no updates to this build for a while. We have been busy getting the remaining six cabs riveted. In the meantime, I was doing some research and designing the model louvered panel doors that were installed on the end hoods of these 1600 series locomotives. We were trying to decide if we wanted to have louvered panels made. These louvers were the result of that idea. These were actual louvers, but not to scale. AND we add to attach each panel together to make one large panel door. Bad idea…back to the drawing board and the computer.

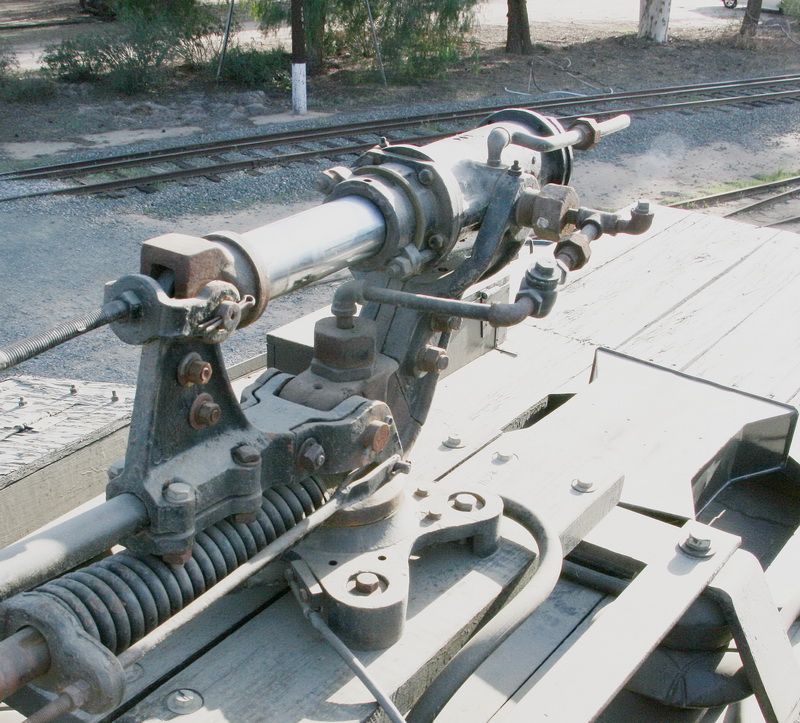

Then last May, I saw a company advertisement on Backyard Railroading Facebook site. A small foundry near Kent, Ohio specializing in unusual detail items for 1" and 1-1/2" scale detail castings and 3D printing work. I contacted the owner of Fair Weather Foundry and asked if he was interested in a project. He was and he said to send a photo of the actual louvered doors on a prototype P.E. electric engine and he would see what he could do. I have quite a few photos of the #1624 P.E. freight motor at Orange Empire Trolley Museum here in So. California. I found a photo and sent it off to him.

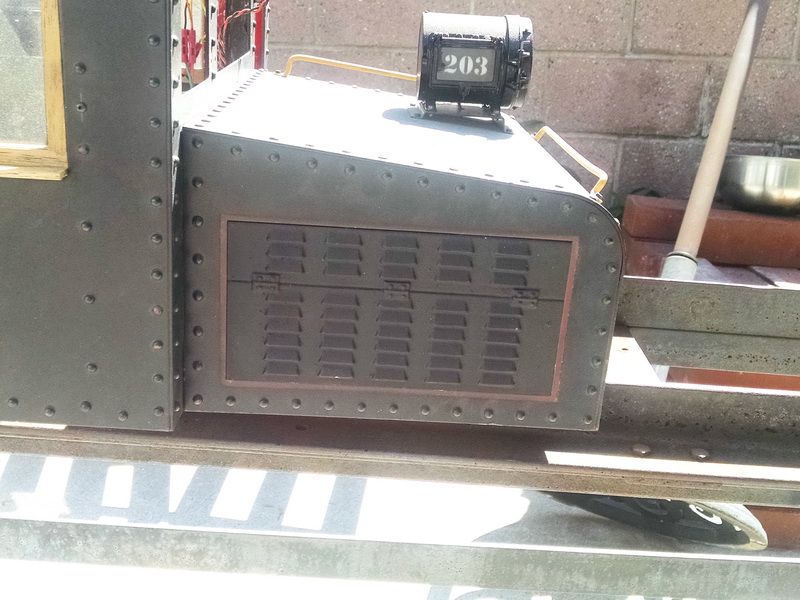

This is the photo and the closeup of the louvered doors.

AND the closeup…

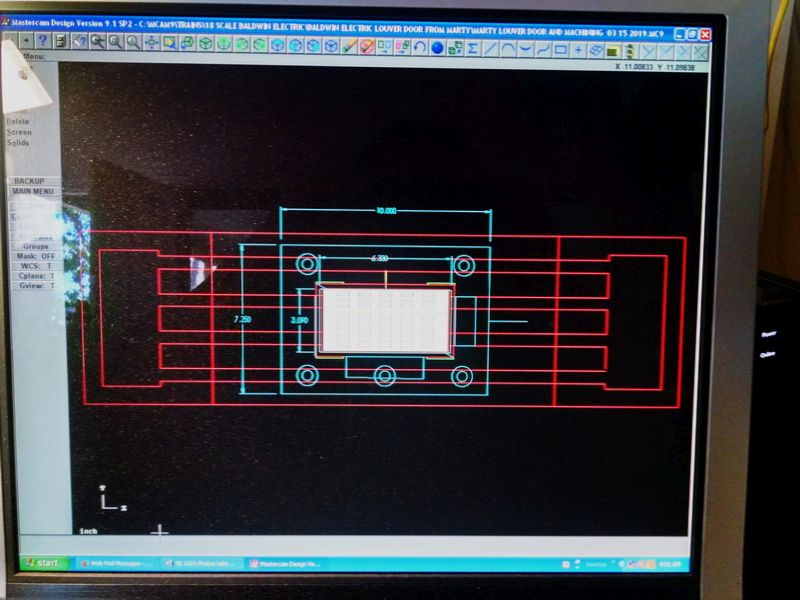

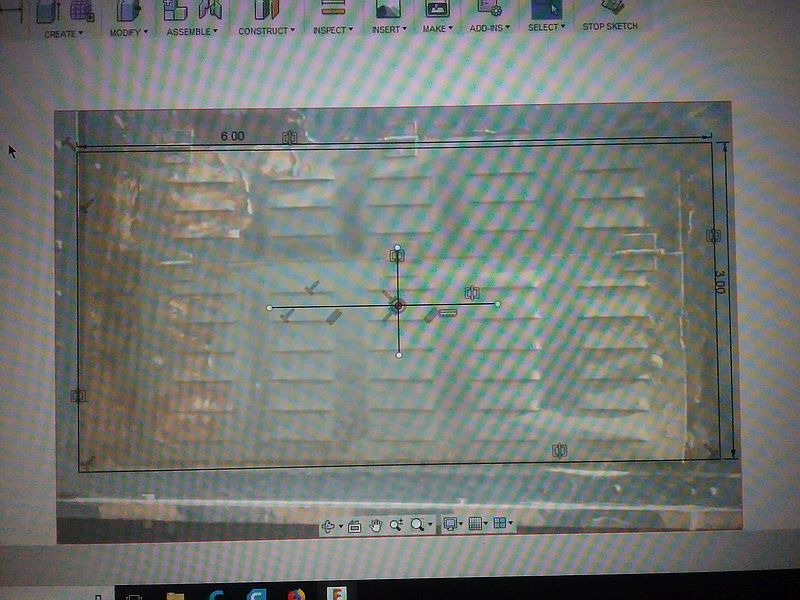

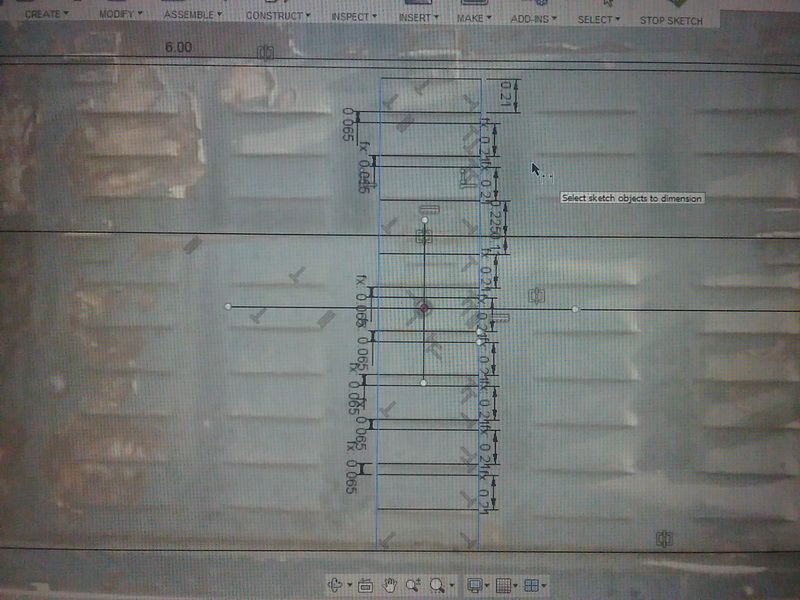

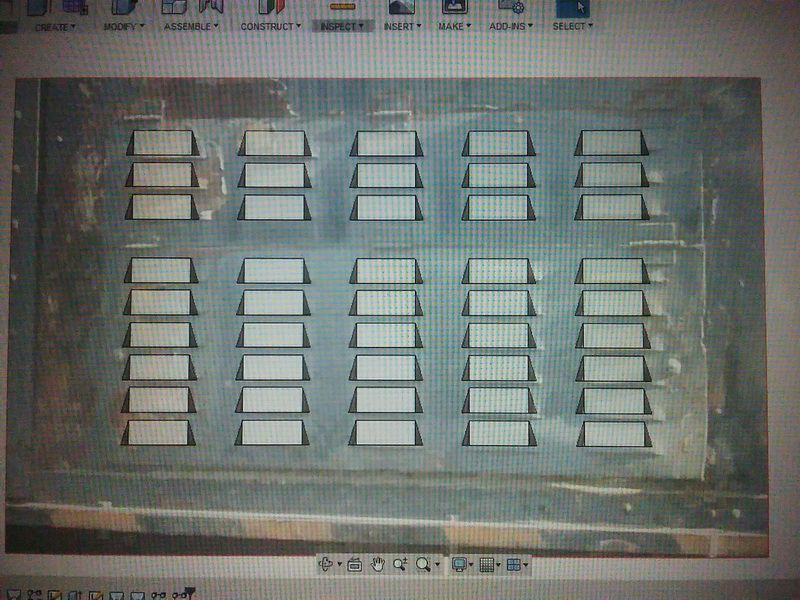

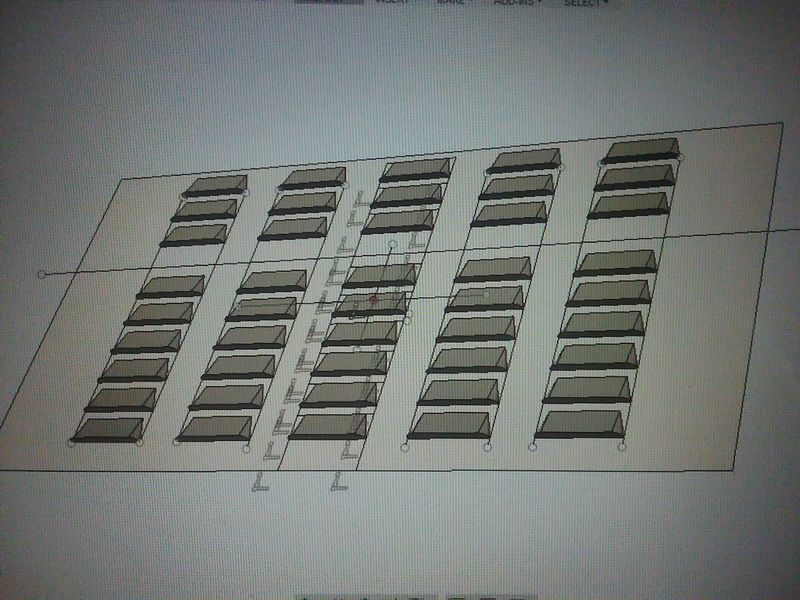

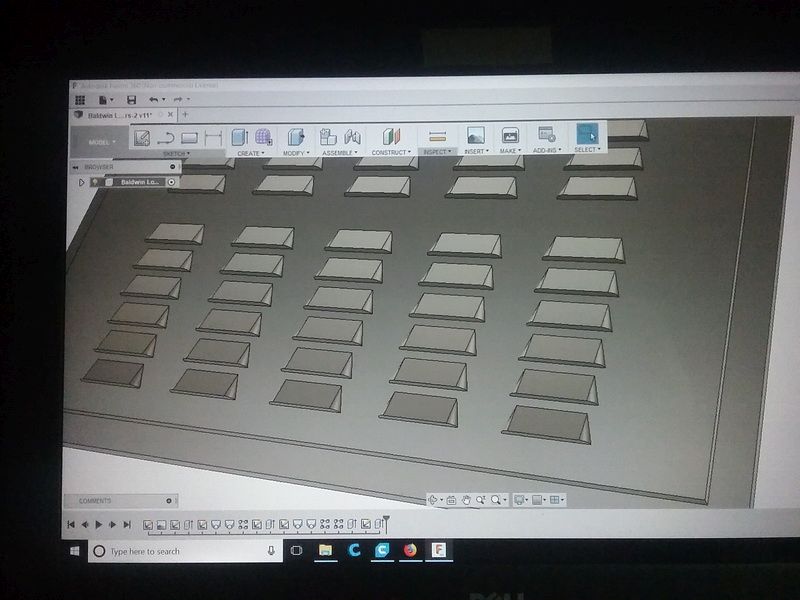

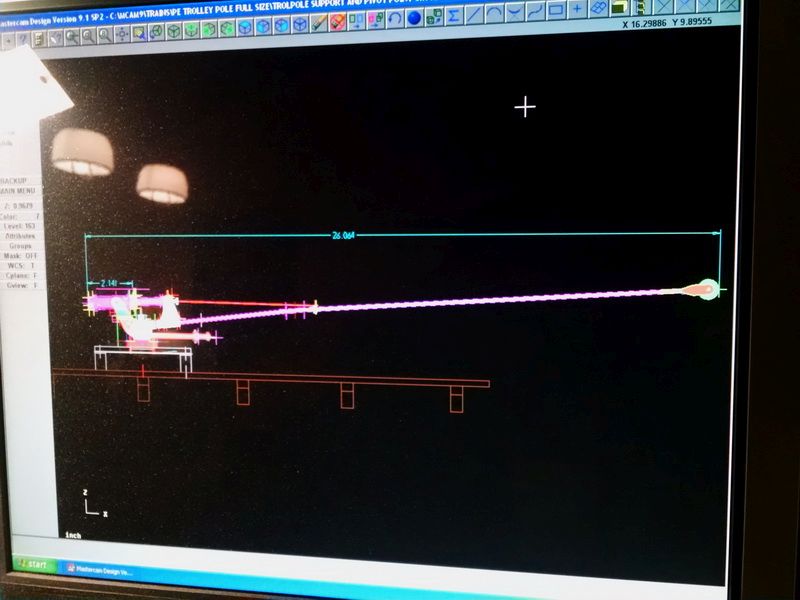

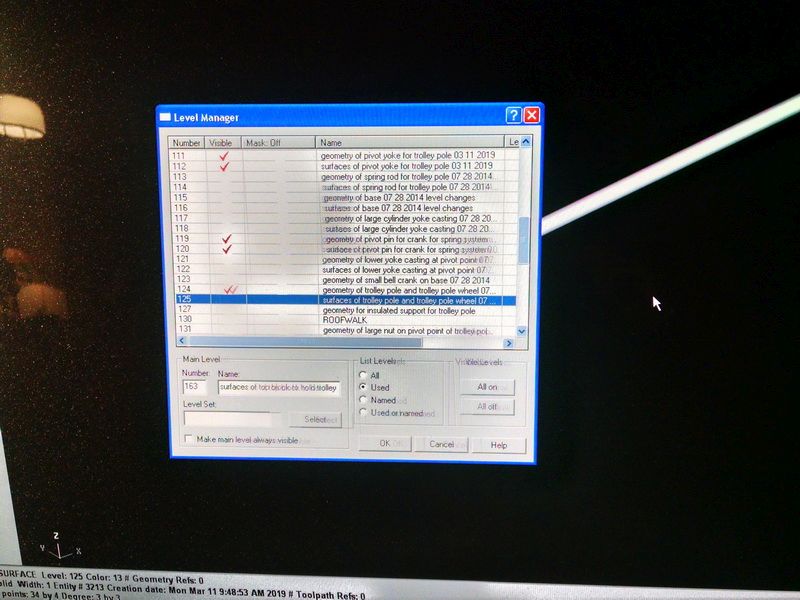

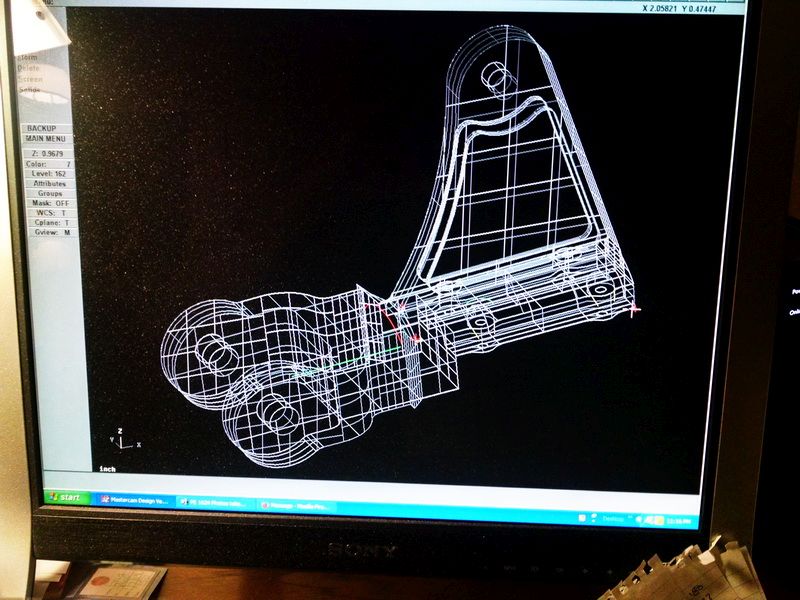

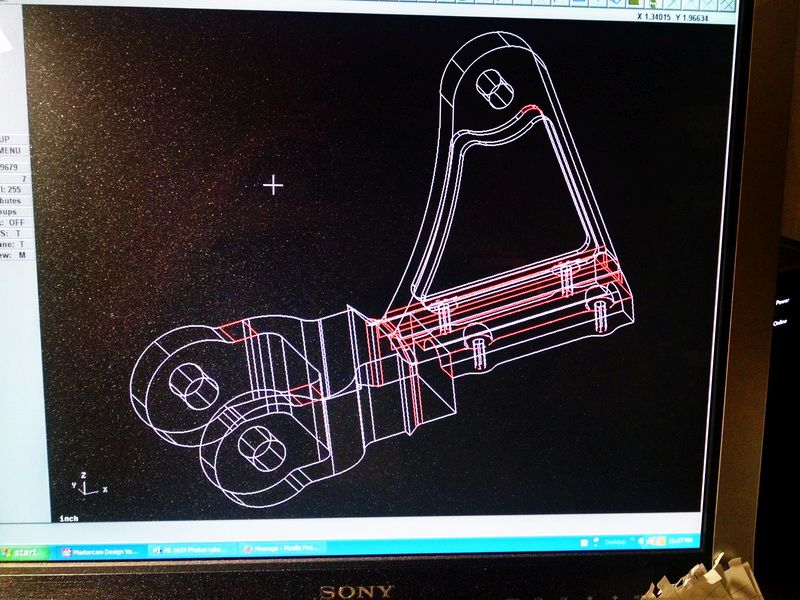

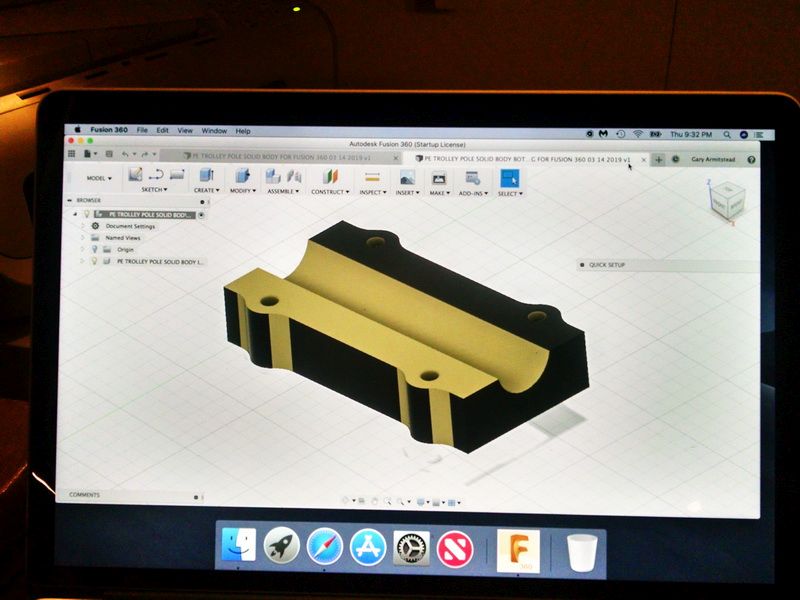

I had my answer overnight! He took the photograph and embedded it in AutoDesk Fusion 360 software. I think many of us use this software to do 3D printing here on LSC. The photos below show how the photo became an actual mold for a sand casting in aluminum!

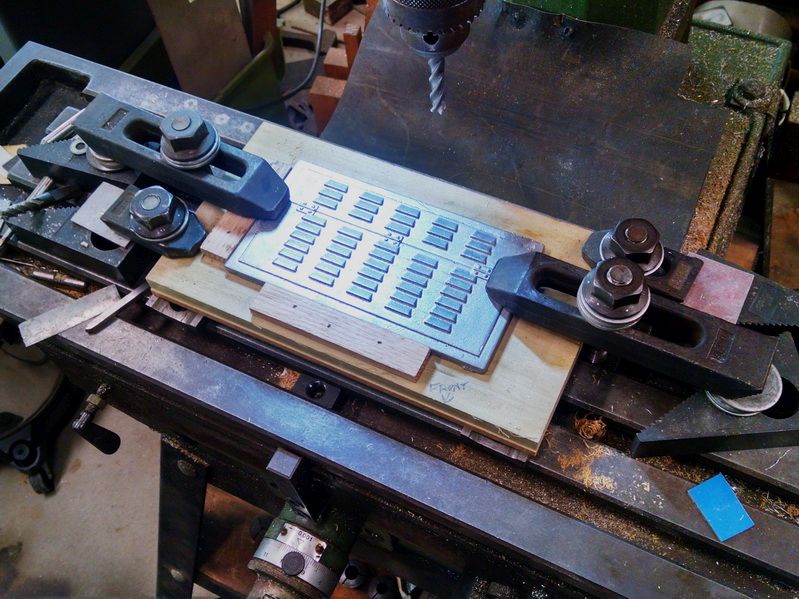

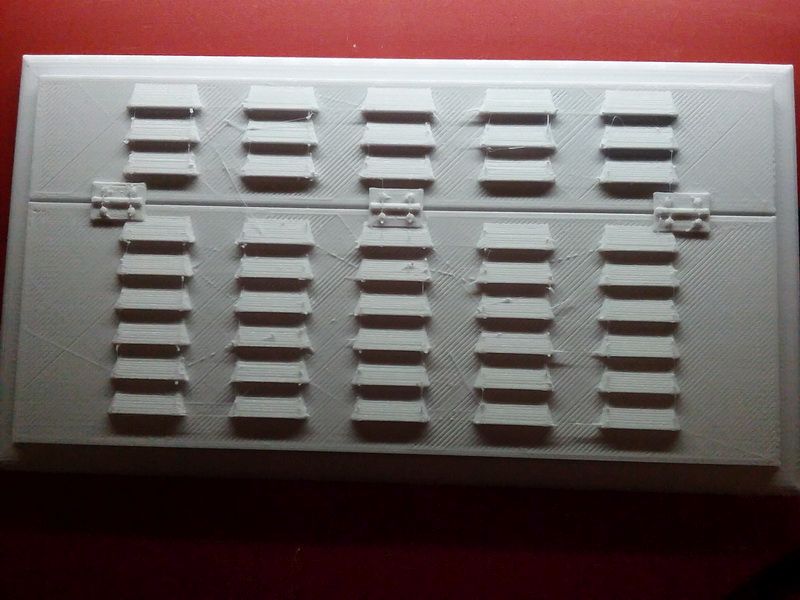

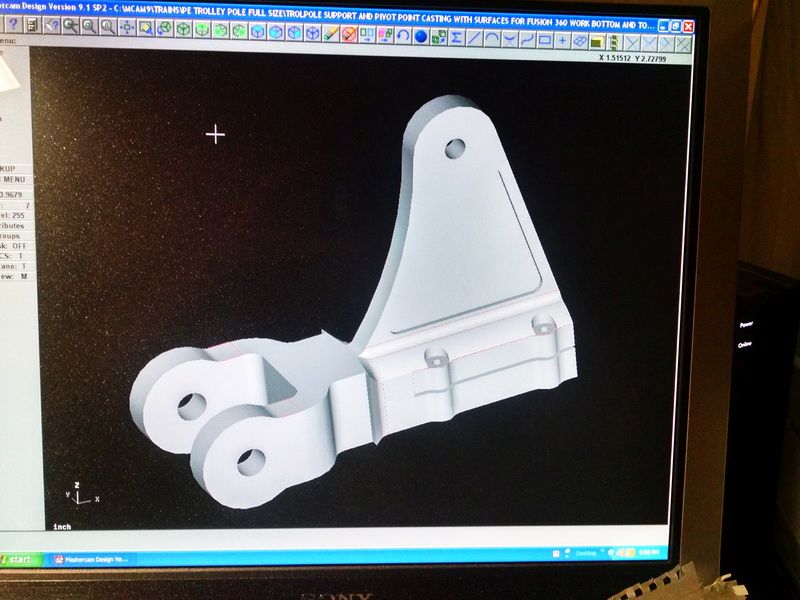

From this Fusion 360 drawing, the foundry 3D printed the master model for the sand mold casting. Took one hour to “print” the master. He did some finish work to get rid of the tool marks and pressed the master into the sand.

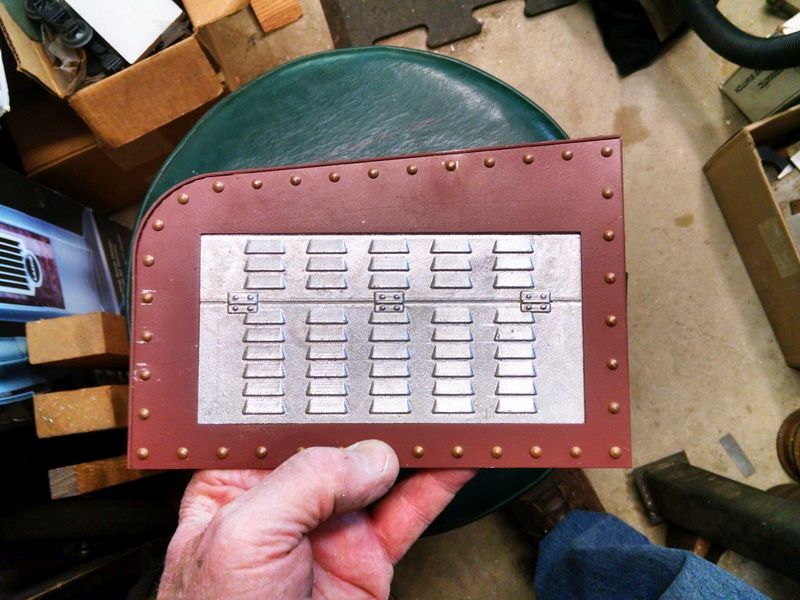

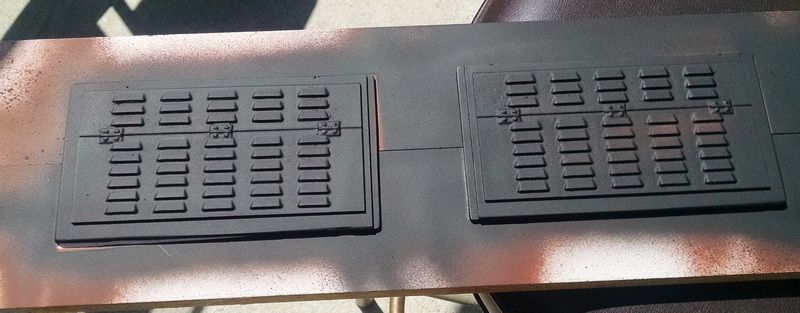

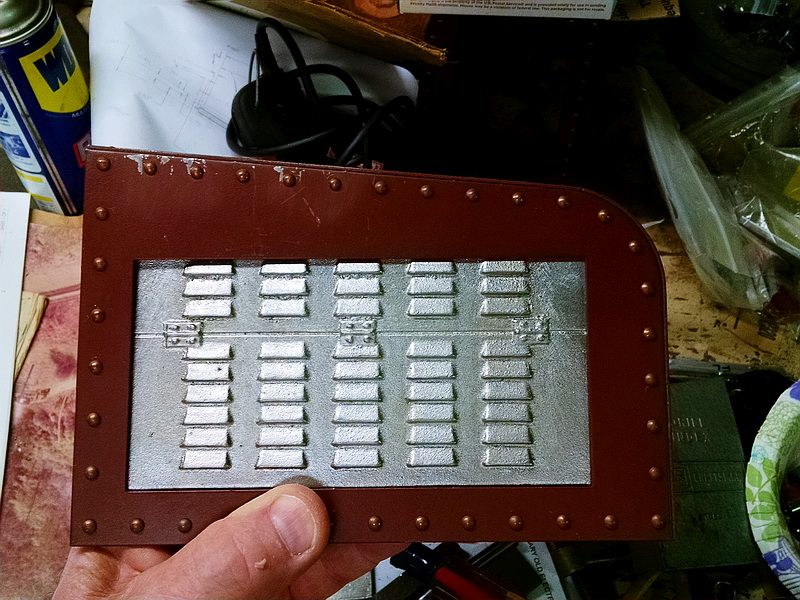

These are the results and the finish aluminjum castings. The crazy thing is that the technology was so fluid throughout the process. No charge to print the mold and $15 each for the castings!

We have to do some milling around the raised area of the casting so it will fit the existing opening in our hoods.

This was the first casting and hjad some blow holes and fall away of the sand. He sent this along for checking dimensions. All in all, it was a great experiment. It opens up a whole new world in making EXACT castings from any photograph!

.jpg)