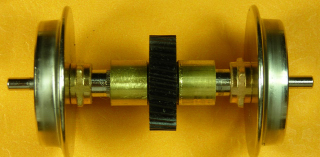

If your USA Trains diesel is running lumpy at slow speed or frequently derailing, the axle sleeves on the drive gear in the motor block may be split. You should not be able to turn any of the wheels with your fingers. If you can, the wheel will slip under load and may not stay properly gauged.

Although axle assemblies are available from USA Trains, the damaged drive gear axle sleeves can be repaired with a collar of brass tube.

The tube required has a 10mm outside diameter and a 0.45mm thick wall. Great Hobbies here in Ottawa has a metric display of hobby brass and can order the correct tube if they are out of stock.

The K&S Engineering stock numbers are 9809 for an aluminum tube and 9828 for a brass tube. In the U.S.A. the McMaster-Carr stock number for the brass tube is 88605K29. Unfortunately they do not ship to Canada unless you are a registered business customer.

The tools required to complete the repair are: a tube cutter, chamfering tool, drill press, small bench vice, sanding board, and flat metal file.

Remove the motor blocks from the diesel, and remove the bottom covers. Lift the axle assembles out, and set the motor blocks aside for now.

Pull the half axles out of the sleeves on the drive gear. Clean the gear with vegetable oil and an old toothbrush to remove any grease. Wash the gear with Dawn dish washing detergent and hot water. Set the gears aside to dry.

Place a pencil mark 5/16ths of an inch from each end of the 10mm brass tube.

Place the tube in the cutter with the blade on the mark. Snug the cutter down, but not too tightly. Holding the tube firmly, make one turn around the tube with the cutter. Snug the cutter down, and make another turn around the tube. After the third time, inspect the tube to ensure the blade has made a groove on the mark and not a spiral thread. Continue the process until the brass collar drops free of the tube.

Repeat the process until eight collars have been cut.

Sand the edges of the collars smooth on a piece of fine emery paper. A sanding block works well for this purpose. A sanding block is simply a 8 1/2 inch by 10 1/2 inch piece of 3/4 inch thick MDF with a piece of fine emery cloth fastened to it with spray glue. Once the glue has dried the edges of the emery cloth are trimmed flush against the edges of the MDF, and non-slip feet are added.

Mount the chamfering tool in a drill press. Use it to bevel the inside edges of the brass collars to remove any flash.

Use the same tool to bevel the inside edges of the axles sleeves on the plastic drive gears to make the axles easier to install.

Remove the chamfering tool, and place an axle sleeve of a drive gear in the drill press chuck. Use a flat metal file to bevel the outside edges of the exposed drive gear axle sleeve to make the brass collars easier to install. Repeat the process for the other seven axle sleeves. Use an old toothbrush to clean any plastic filings from the axle sleeves.

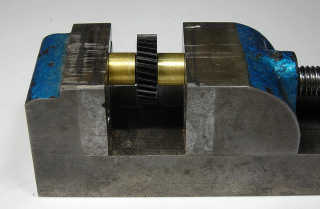

Turn a brass collar onto each of the drive gear axle sleeves. Place the drive gear into a small bench vice, and close the vice until the brass collars are flush with the ends of the plastic axle sleeves.

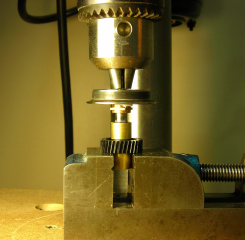

Remove the gear and place it in the vice with one of the axle sleeves and brass collars facing up. Close the vice until the jaws just touch the bottom brass collar. Place the vice on the drill press platform.

Fasten one of the wheels in the drill press with the inside axle facing down. Use the drill press to push the axle into the repaired plastic drive gear sleeve in the vice until just 1/32nd of an inch of the splines on the axle are showing.

Turn the axle assembly over in the vice. Place the other wheel in the drill press with the inside axle facing down. Use the drill press to push the axle into the other plastic drive gear sleeve until just 1/32nd of an inch of the splines on the axle are showing.

CAUTION: Do not push the wheels beyond the NMRA standard for back-to-back clearance of 1.575 inches. Attempting to draw the wheels back out to widen the back-to-back clearance may break the axle sleeve off the drive gear.

Carefully use the drill press to adjust the back-to-back clearance. The minimum measurement on an Aristo-Craft track and wheel gauge or a caliper can be used to take the measurement.