Some of Yunz know that I belong to 2 HO FeMo clubs, now more of Yunz know. I belong to a small club called the South Hills Model Railroad club, because Dave Bodner drug me kicking and screaming to one of the club’s meetings when the club was just getting started, and forced me to join. Just kidding, but Dave did invite me to the meeting, and I have to blame someone for delving back into HO. I also belong to the NMRA division 2 FreMo group. Besides having a pair of modules, I also am trying to put together some train sets to run. My latest adventure is resurrecting an HO Tyco 10 wheeler that I bought at a train show. Ok, its actually a bit oversized for HO, but it was a popular locomotive back in it’s day.

First thing I did was to set the train up on an oval of track and apply DC power to the track. If the thing won’t run, I may be done right here. Sure enough, it didn’t want to run. So I opened it up, and the motor contacts, the commutator, was black. So I removed one of the motor brushes and carefully cleaned the commutator with Brasso. Once I put it back together the train actually ran.

At first it ran jerky, then it derailed. Upon inspection I found that the drawbar screws were so tight that the drawbar could barely move, and the tender truck screws were cranked down so tight that the trucks would not swivel. After backing off those screws a quarter turn or so, I tried again. Again she started off real jerky, but after a minute or two, she started running smoother and smoother. And she sounded just like the one I used to have when I was a kid.

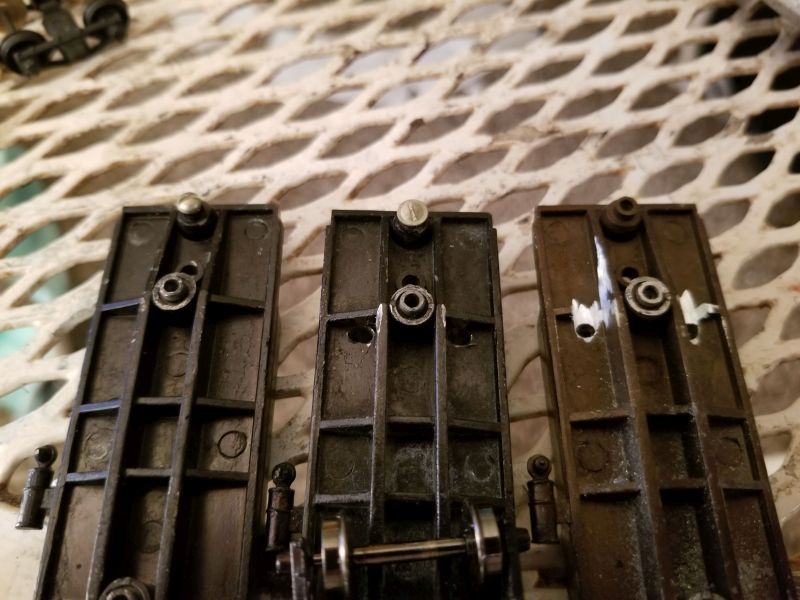

Once I knew that the mechanism wasn’t trashed, and that she would run, I started my upgrade of her to DCC. These older locomotives have open framed motors in them. Those kind of motors tend to draw a nice amount of current.

My ammeter was showing .4 something amps when I was running the locomotive. I say “something” because the next 2 digits of the meter were flickering so much that I have no idea what the average of them would have been. To improve the performance of the motor, I replaced the original magnet with super magnets from Micro Mark.

I could not figure out what way to put the new magnets in, because the motor’s original magnet was so weak that super magnets would stick to it in any direction. So much for the “opposites attract” theory.

I put 2 strips of electrical tape on the bottom of the motor and reinstalled it with a nylon screw. That way the motor is electrically isolated from the locomotive’s frame.

Running the locomotive now, it only draws .2 something amps, a definite improvement.

While I was rewiring the locomotive, I replaced the headlight light-bulb with a bright yellow LED. But the headlight wires would not fit in the groove in the boiler weight.

After little work with a file, the 2 wires fit in the groove originally made for one wire.