Seems like I need to splain the actual design. In short, the geometry was “set in stone” when I built the surrounding roadbed and mountain, both of which are (thick) concrete. Nine years ago I attempted the first version design, but just a couple weeks ago did a full redesign (to simplify things… long story, but the 1st version was whack job).

A week ago, I made a paper template showing what my new design “expected” from the existing conditions, because the roadbed forms were set out per the same CAD plan. I laid this template on the track, to ensure all lined up.

But tolerances are a b!tch, especially in this case of wonky concrete forms & etc. Nothing real matched my CAD-driven paper template. So I took measurements, marked the template up, corrected the template in CAD to match the conditions, re-cut the template and put it back out.

Here’s template attempt #4, which finally matched the conditions in where all the roadbeds are, and where all the bents should go. And how tall the bents need to be.

An experiment in photogrammetry, fwiw:

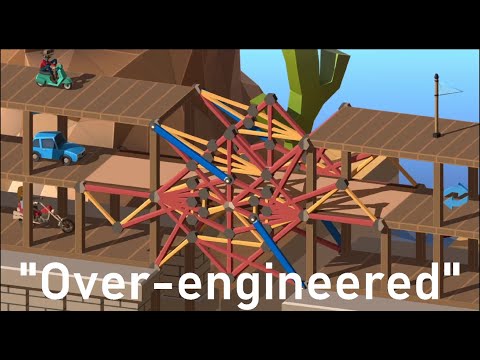

Now having a reliable geometry set, I reworked all the trestle design. Which will take a long time to build, because that’s how I roll (slow).

To my mind, installation is the tricky part, in conveying CAD-driven geometry back into the 3D site, for setting for piers. I imagine there are vastly simpler ways of doing it, but here’s my plan.

First, take out the track and the unnecessary 4x4 plywood supports, and put in temp blocks above the lower roadbeds.

I have a pier-pouring jig design in mind, very subject to further thought. Lasered scrap 1/8" plex, suspended via 3/4" pvc pipe from the existing plywood bridge. The point here is forcing the CAD geometry back to the site. It’ll require the BIG “hammer” [edit: I added quotes to “hammer” because Bruce’s comment made me] to get some concrete out of the way.

When that’s done, the remaining posts are removed, while the jigs are strapped to the plywood to hold it in place. Then come the remaining jigs for the 2nd set of piers.

In both pier steps, cement is poured through the upper holes of the jig boxes. The cement will reach down into the terrain, however it needs to. Upper pier surfaces are ground flat after the forms are removed.

And then Little Red Riding Hood said, “What nice teeth you have, grandma!” And mostly everyone lived happily ever after.

But back to my fairy tale, here’s the intended result.

Assuming all goes perfectly* with the bents and bent-assemblies, here’s how they will perfectly* go on the perfectly* cast piers.

*Re “perfect”: a relative term. Here used in the sense of being within 1 foot of the intended location.

Then the deck…

And the build jig (insulation foam with lasered cardstock templates):

And the eventual miracle:

So that’s my story.

888:>Cliffy