David Maynard said:

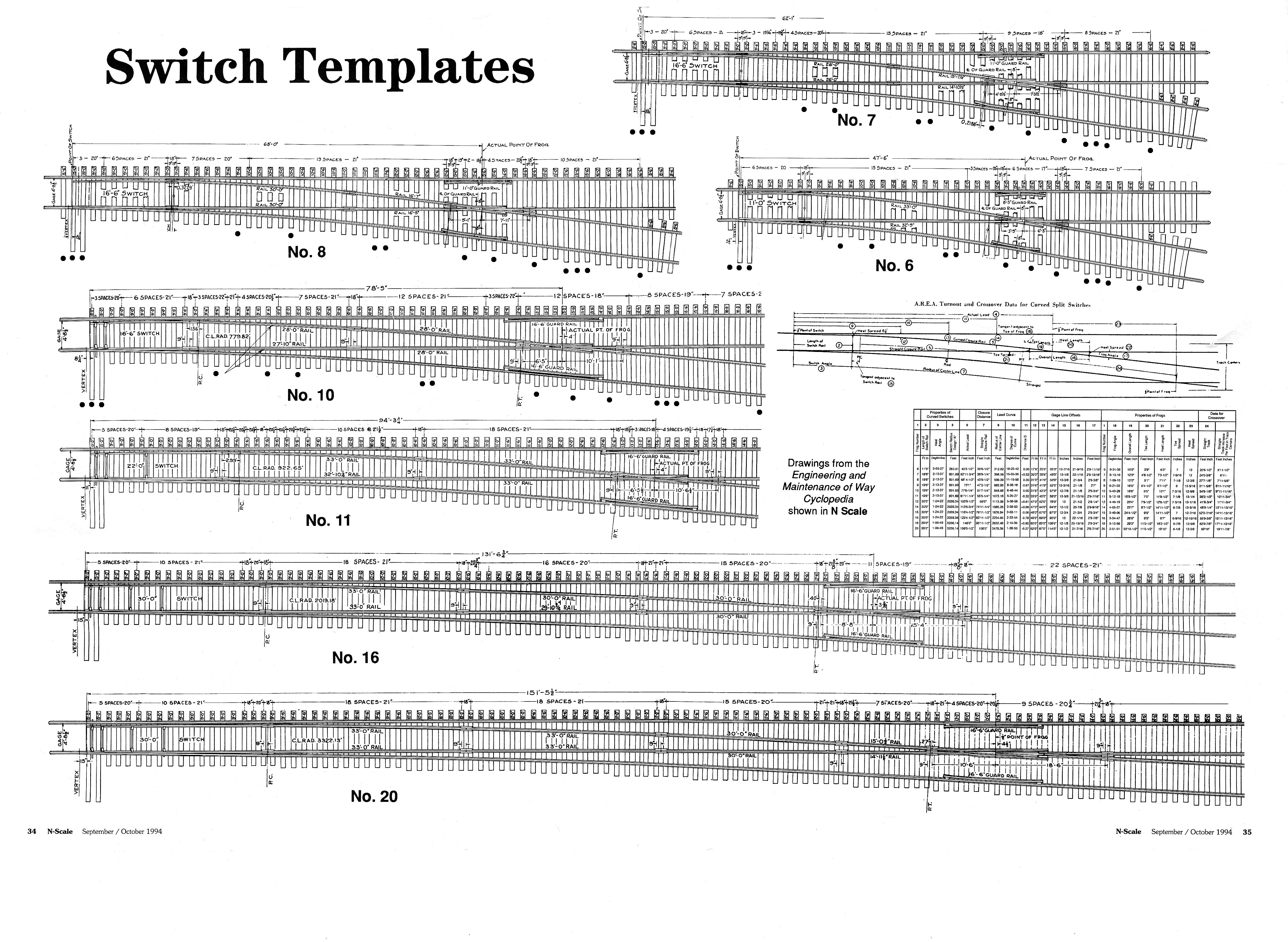

See, now Devon is asking kind of the same thing I was asking. The closure rail (traveling from the frog to the point) begins its curve when/where? If the closure rail ran straight for a long enough distance, then the point would really jar the wheels from straight to a path leading straight to the frog. A few pages ago I was asking about the curvature of the closure rail and here we are again. If the closure rail starts its curve right at the frog casting, then I understand how the length of the closure rail/point is figured out. If not, then I am still in a fog.

Craig, I understand the the frog is straight, and the stock rail is also straight opposite the frog. Its the closure rail curving from the frog to the tip of the point that I, and believe Devon, are a bit lost on.

In the drawing of the frog that Craig has so generously provided us, above, part of the casting extends to the left of the vertex of the frog. I don’t say point, to avoid confusion, but that is what it is. That portion to the left of the vertex of the frog from the beginning of the closure rails, and, as part of the casting of the frog, are necessarily straight, so that the frog casting can be used for either a left or right hand turnout. The curve of the closure rail likely begins where the casting ends.