A short history:

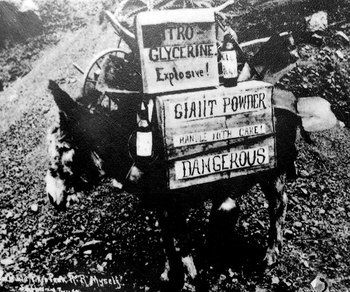

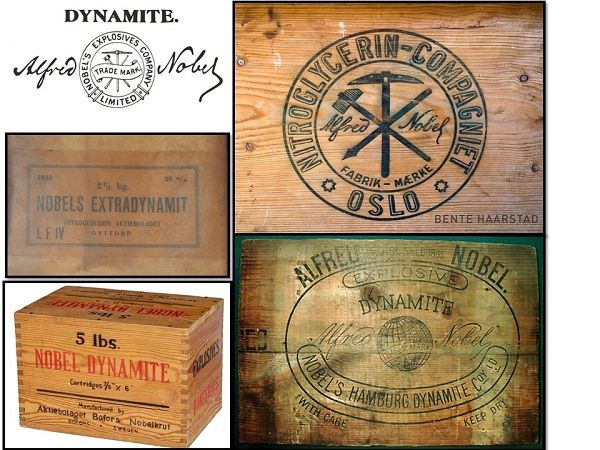

Dynamite was patented by Alfred Nobel in 1867 after many years of development. His goal had been to replace its volatile and often unpredictable precursor black powder for industrial blasting. Nobel had thought to use Nitroglycerin (which is derived from black powder) but needed a way to to stabilize it for transport and use. His design called for the unstable explosive to be absorbed into sorbents such as sawdust, ash, cement and ground sea shells without diminishing the explosive power. He finally came up with diatomaceous earth which was then wrapped in a waxed paper tube. This final form was an outgrowth of two of his other inventions: a proprietary method for synthesizing nitroglycerin and the invention of the mercury fulminate blasting cap.

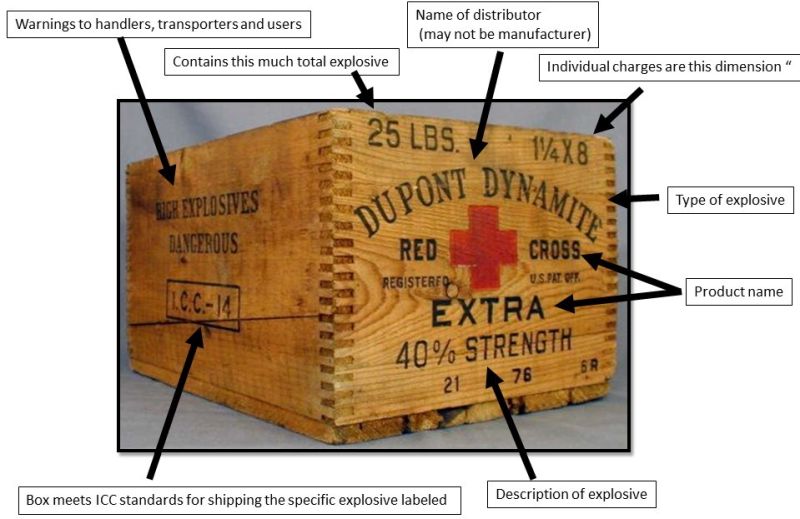

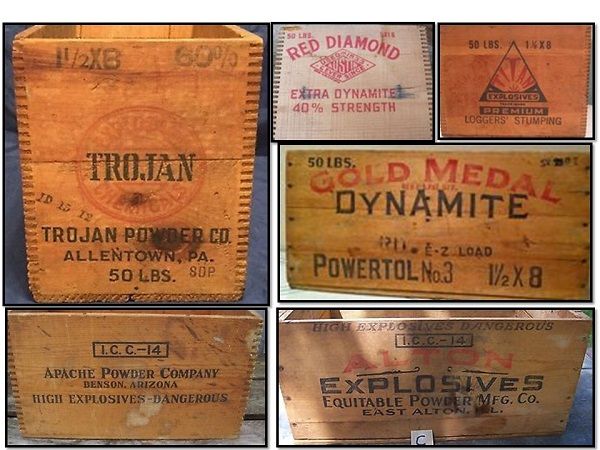

This revolutionized rock blasting and by zealously guarding his patents he accumulated one of the largest fortunes in the world. Today dynamite is made from more stable materials like ammonium nitrate. One unforeseen market is in the antique market where enthusiasts pay huge amount of money for old crates and wrapping papers that have been reclaimed from sticks of dynamite.

Modeling Dynamite on the Layout

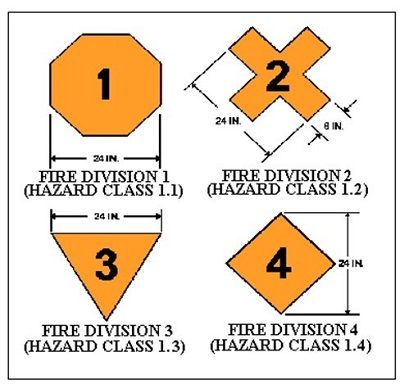

Even though the two types of dynamite existed and overlapped each other for decades, I recommend WW II as the central point of change in how dynamite (and other explosives) were labeled, handled and used. This is because so much new technology was invented during the war years but primarily because of the standardization of procedures and products. If you model prior to 1940 then your railroad is most likely using nitro based dynamite. If you model during or after 1941 then the ammonium nitrate version would be more common.

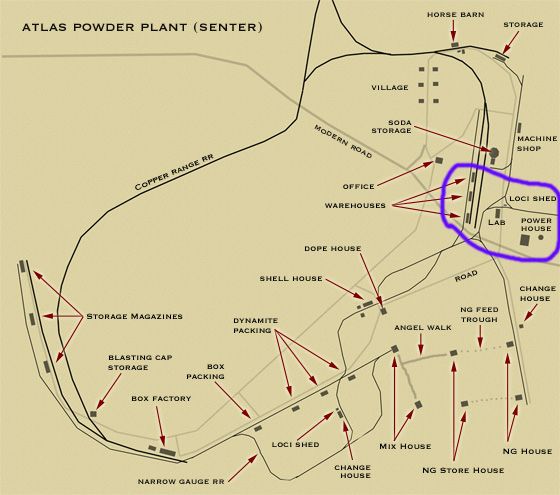

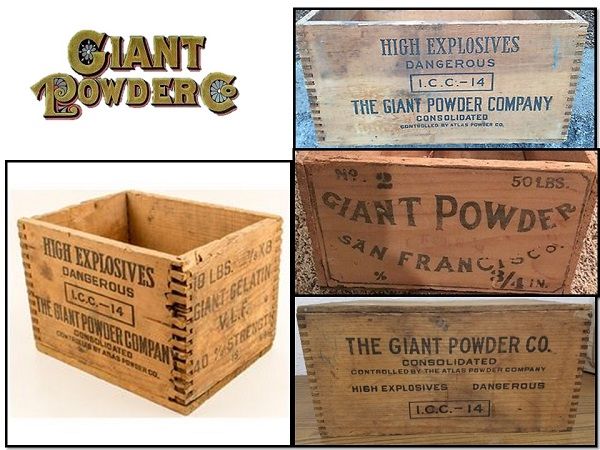

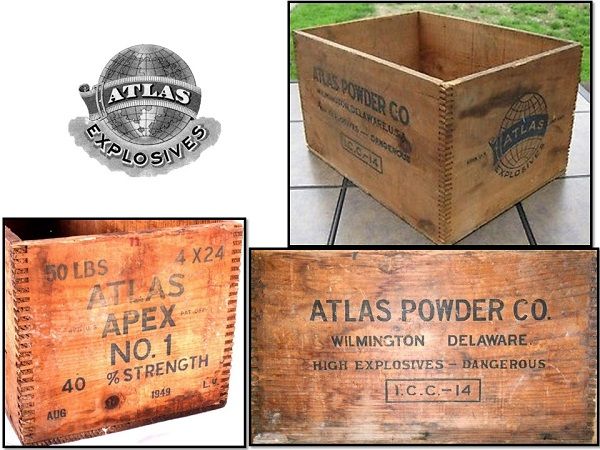

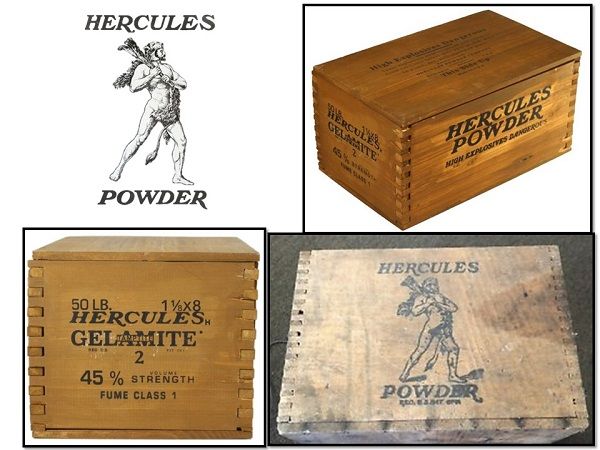

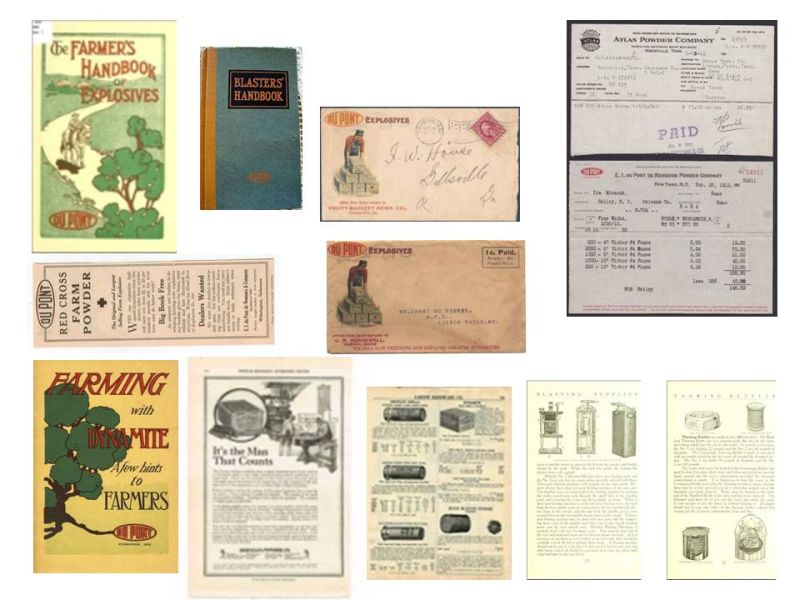

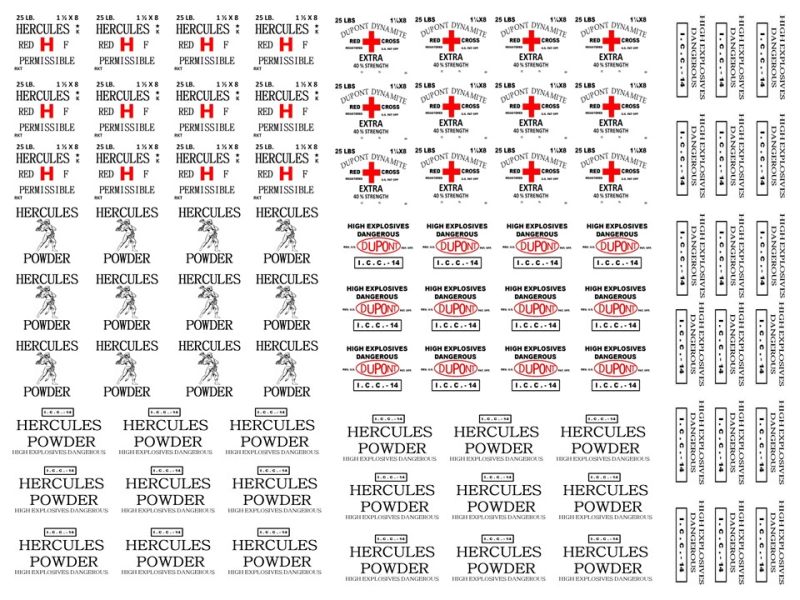

Dynamite in the US was produced first by Nobel and then quickly manufactured under license by Giant Powder Company beginning in 1867. Giant and it’s licensing was acquired by DuPont in 1871. This transferred to both the Atlas Explosives and Hercules Powder companies in 1915 following the the court ordered break up of DuPont under the Sherman anti-trust act. Atlas closed the Giant company facility in 1961 and changed its name to the Atlas Chemical Company after leaving the explosives market. That means that different labeling existed at different times. There were other companies producing nitro dynamite during this time but with slightly different formulas and none that could use the name “Nobel”.

Alfred Nobel & Company (Dynamit Nobel/ Nobel AG) from 1867-1918, 1938-1953, 1957-1990 (production ceased under the Nobel Name) Manufactured in US by DuPont 1867 to 1912

Giant from 1868 to 1905

DuPont from 1880 to 1986 (after 1915 Atlas actually manufactured DuPont Dynamite)

Atlas from 1912 to 1961

Hercules from 1912 to 2008

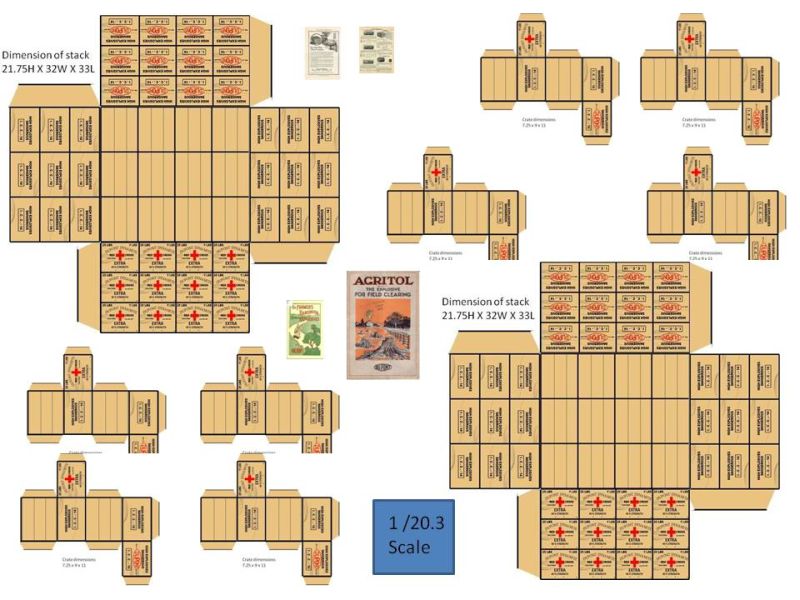

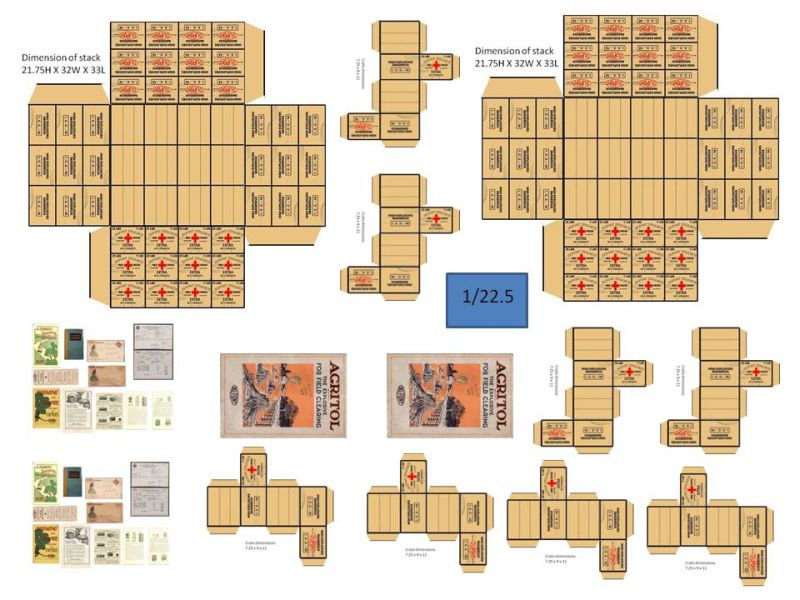

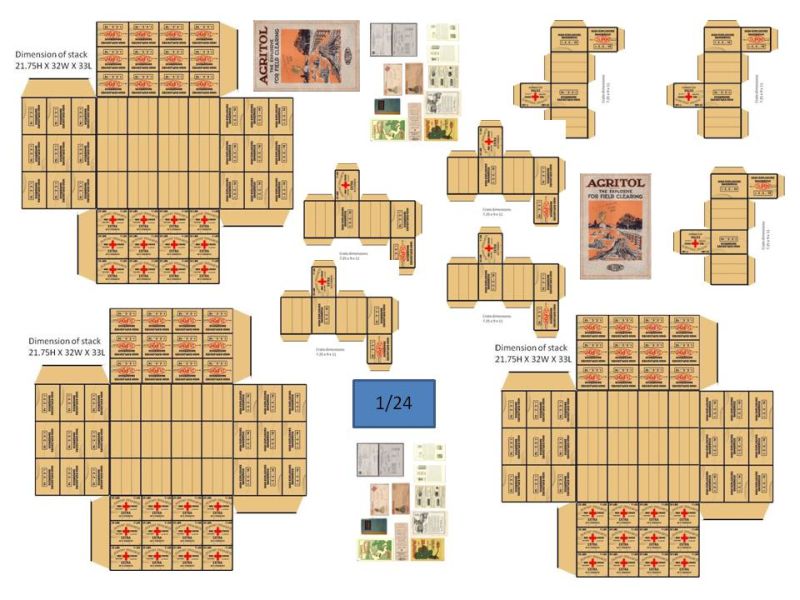

You are gonna need some crates. I made these graphics for printing on white card-stock then found brown paper. Still looks good printed on that. I also made decals for putting on resin cast / painted crates (because I do not have enough frustration and aggravation in my life already). I cut pink foam on the bandsaw to make a core. It is easier than it sounds and makes the crate hold their shape really well.

Print the paper on a regular sized piece of card stock. The decals you will have to adjust for your scale. The posters and books will also have to be downsized.

You may be wondering about the Red Cross on some of the boxes. This was a brand marketed by DuPont and had nothing to do with the Red Cross Emergency organization.

Post WWII

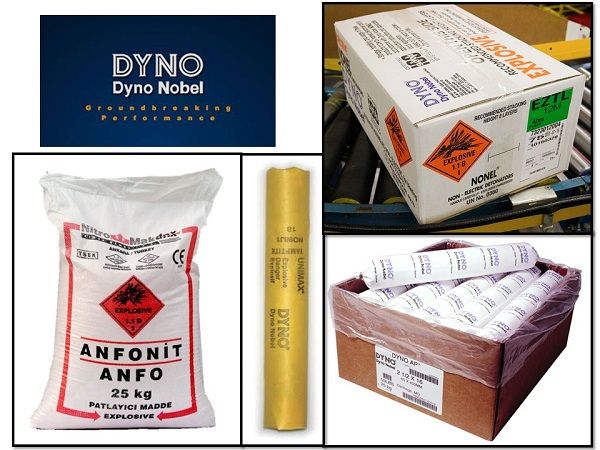

Long before the war several companies had been working on ammonium based blasting agents called water-gels. These were not as powerful as the nitroglycerin based dynamites but were safer to handle, cheaper to make and had a much longer shelf life. DuPont, Atlas and Hercules all manufactured their versions of these products but eventually one company emerged as the last man standing. It turns out to be back where it all began, a company started by Alfred Noble. Headquartered in Australia Dyno Nobel has plants in Chile and the US where it makes modern blasting gels for North America. Dyna Nobel makes most of the explosives used around the world repackaging them for other companies under their brand names.

What really makes these superior for quarry and engineer work is how they detonate. They are slower than dynamite and produce large volumes of gas. This increases what is known as the duration of pressure resulting in a lifting rather than a puncturing force. Imagine standing in front of a pane of modern safety glass and firing a gun. The bullet would bust a hole in the glass and cause some cracks. But if you hit it with a sledgehammer the pane would crack and pop out of it s frame. This is because the force is slower and has time to spread over a greater area of the surface. The shoving or lifting effect is very desirable when breaking rock or moving soil.

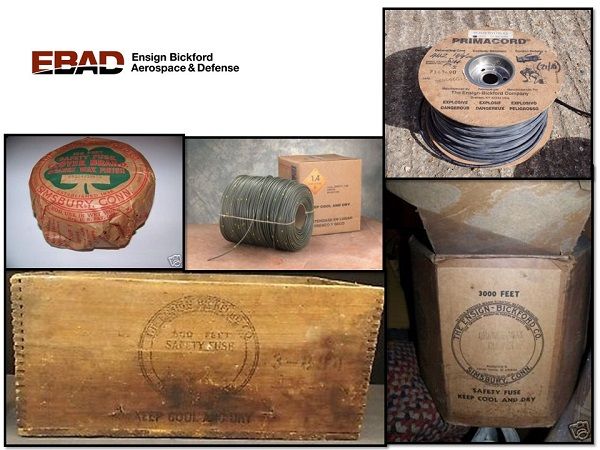

These explosives can be brought to the work site as cartridges and inserted in boreholes or mixed on site as slurry and pumped into cavities. The two things that really make these work were the invention of prima-cord and safety fuse. Both from a company called Ensign-Bickford. Prima-cord is made from explosives and ties separate charges together at the rate of detonation. Safety fuse burns at a steady and dependable rate unlike cannon fuse (black powder based) which could be erratic or even go completely out.

So you modern guys can include the older dynamite makers or the two that are unique to the modern era.

William Bickford began producing safety fuse in 1830. It became Ensign Bickford in 1836 and developed Prima-cord in 1936. It became the Ensign Bickford Aroespace & Defense Company in 2001

Dyno Nobel founded in 1865 and has manufactured blasting gels from 1956 - present (site mixed began in 1960 under the name IRECO)

Sorry I have no printables for this era.

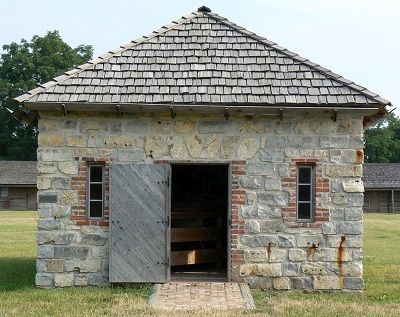

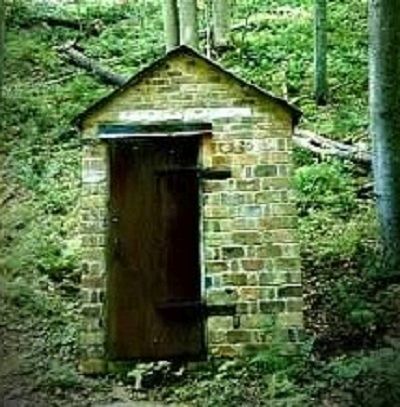

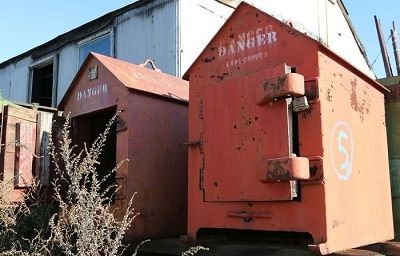

Well now we have to transport it and store it. I will get to that tomorrow.