A Question. How can I test for amps on my track? Is it possible that my Crest switchable supply is dying? The Crest has a 23v 12amp output. I have it connected to a Revo base unit that puts out PWM which was messing with my older sound system and lights so I bought a converter to put it back to Linear. I have tested by bypassing the converter and going to PWM and the trains still act sluggish.

The biggest power user is my track cleaning rig I send out before running any train. It has a USAT S4, a NW2, a custom rail broom and a custom car dragging 3 cleaning pads. This train has been slowing down in odd spots. At the far end of the RR, the furthest away from the power pack there is a drop in voltage by maybe one volt. I have several power feed points spread over the 800’ of track.

My other trains are also slowing but they do not pull as much power as the 5 motor Mow train.

There is a meter on the Crest unit but it stopped working years ago.

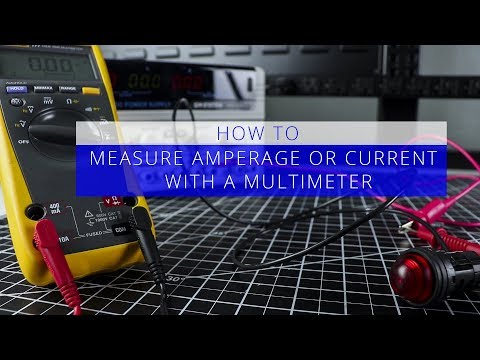

Without going too deep into the electronic aspect what is the best way for me to test my power pack to make sure it is still putting out enough amps?

I have a basic multi meter.

Is there a simple diagram I can use? I don’t want to blow anything up.