Hey guys, thanks so much for the kind words. I’m still learning but I think I’m getting the hang of it more or less. It is a fun machine.

Oh yes, I’ve melted my share of sheet, makes a huge mess, breaks bits, yuck.

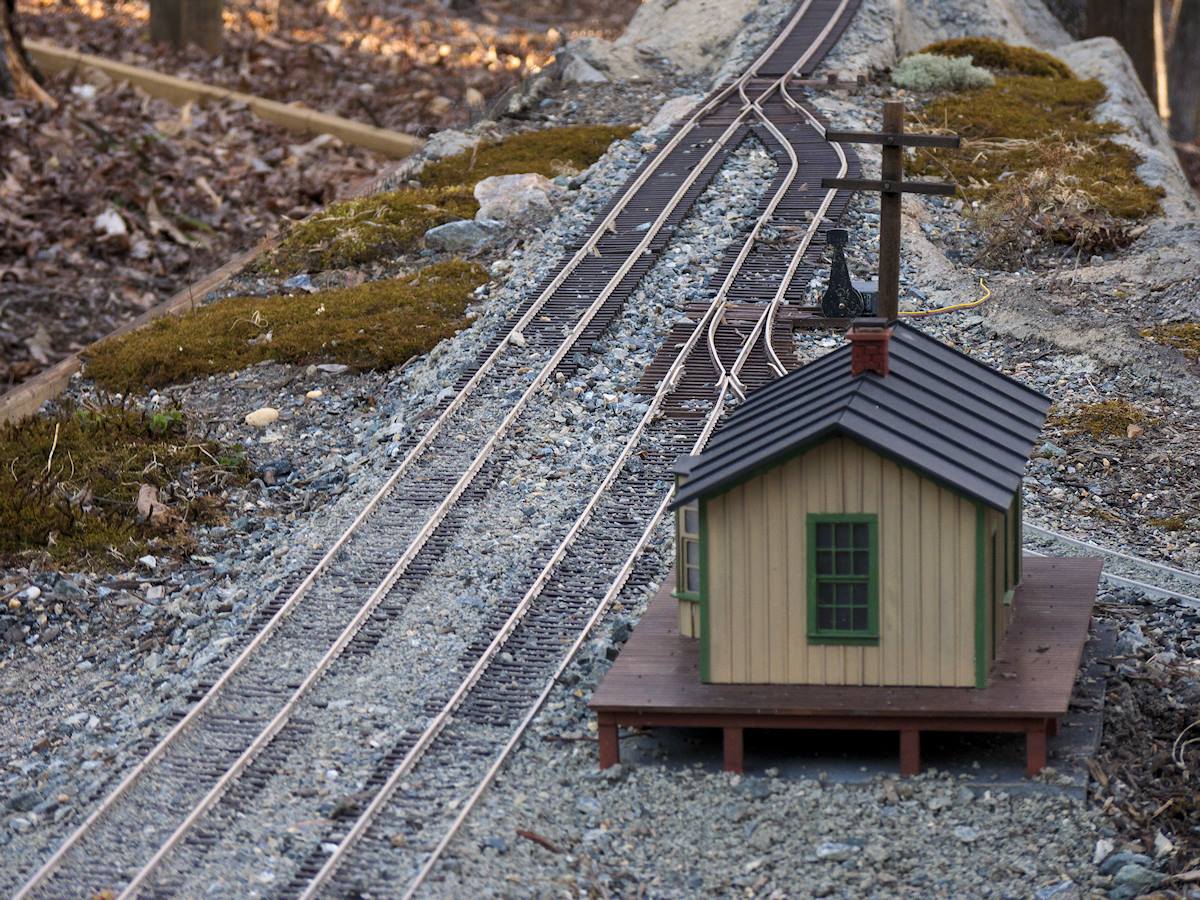

But I have found that if I throttle my router back to 7500 rpm, (I have a ‘super PID’ which lets me dial in the speed) and then run the feed rate at about 20 ips I get good results. I also make a couple of passes if the material is more than say .030. So the depot was, for the most part, two passes. You want to see really fine little ‘chips’ and then you get a nice clean edge. I use 1/32 inch bits from PreciseBits: MM208-0313-013F which is a two flute fish tail end mill which seem to work quite well:

http://www.precisebits.com/products/carbidebits/precisebit-soft.asp?tsPT=!!!2Flute_EndMill_FishTail!!!

Also, one other thing that was throwing me for the longest time is a G code command that CamBam puts into the generated machine file - G64 which means ‘constant velocity mode’. This was rounding all the corners in the windows and driving me nuts. If you instead change that one command to G61, which means ‘exact stop mode’, the router feed will come to a stop if it needs to so the corners are sharp. You can only get the inside corners so sharp since the bit is round after all but the difference is quite noticeable.