Has anyone used the line of bridges offered by SplitJaw? I have a long elevated section of track that I need to build, connecting my indoor and outdoor layouts. I’m looking at their through-girder bridges for this. They have some incredibly long spans (up to 8’), and I’m wondering if they are up to the task of carrying a 40 lb engine like the Hudson.

I was wondering the same thing!!!

Let me know what you find out. I’m specifically interested in how you support the 8’ span… if no middle supports, that would be cool, although they say the sides get taller.

Eric Reuter said:

Has anyone used the line of bridges offered by SplitJaw? I have a long elevated section of track that I need to build, connecting my indoor and outdoor layouts. I’m looking at their through-girder bridges for this. They have some incredibly long spans (up to 8’), and I’m wondering if they are up to the task of carrying a 40 lb engine like the Hudson.

Well I do have experience with these bridges and I bought a 48" drop girder about 9 or 10 years ago (as an experiment  ). At that time they were about fifty bucks each. I know that Split Jaw says they are paintable PVC…I thought the material was more like “glorified” heavy duty packing used to hold electronics products from moving around the shipping box :)! I would give you mine, but it would cost more to ship than it"s worth. A year after I purchased this product, I contacted Scott Lindsay in Tennessee and had him make me custom bridges (also drop girder). He makes up custom kits where the parts are ABS and cut with an NC router. They go together very easily. You use the same glue as you would use for ABS plumbing. Very detailed and stronger than the Split Jaw products.

). At that time they were about fifty bucks each. I know that Split Jaw says they are paintable PVC…I thought the material was more like “glorified” heavy duty packing used to hold electronics products from moving around the shipping box :)! I would give you mine, but it would cost more to ship than it"s worth. A year after I purchased this product, I contacted Scott Lindsay in Tennessee and had him make me custom bridges (also drop girder). He makes up custom kits where the parts are ABS and cut with an NC router. They go together very easily. You use the same glue as you would use for ABS plumbing. Very detailed and stronger than the Split Jaw products.

I was trying to find Scott’s contact info, and have lost it… can you provide it, when I last researched his stuff looked best, although I don’t think he makes curved stuff.

Thanks Gary

I found his website. Those look really nice, and the prices seem too good to be true I will look into having him do some bridges for me.

Like to see his deck girders. Are you going to contact him? Looks like the site has not been updated since 2015.

Tell him you have another customer to replace what you see in the picture above shows, in 4 places.

Greg

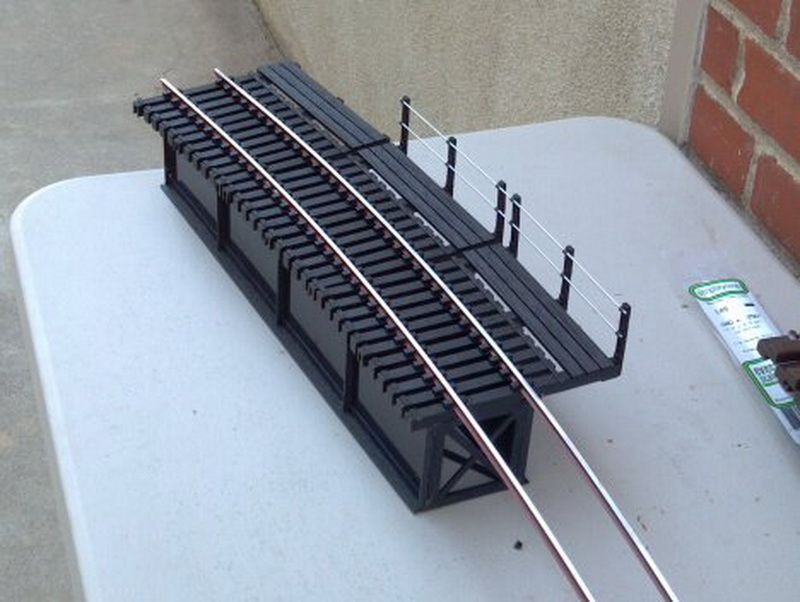

Scott built these for me a number of years ago and they have held up fine. Several years on the old RR and one of them is doing service on the new line.

Each span is 6 and 1/2 feet long and once glued together, solid as a rock. All the splice plates come pre-drilled for the decorative rivets, I used brass escutcheon pins.

Rick, is that “aluminum” paint?

Greg

Greg,

The material is black ABS, as Gary said, and If I remember right I used Rust-Oliums “Hammered Silver” to spray it. I like the “Hammered” colors as they add some texture to the finish.

Here is a little close shot of one of the spans in it’s new locatiom.

Greg Elmassian said:

I was trying to find Scott’s contact info, and have lost it… can you provide it, when I last researched his stuff looked best, although I don’t think he makes curved stuff.

Thanks Gary

Greg,

I guess Eric provided the contact info for Scott. This is the page for his “G” bridges: http://www.jsrailcar.com/g-gauge.htm He provided some drop girder deck bridges for me about 6 or 7 years ago. I have never set these bridges up because I went back to the ride-on scale trains and had less involvement in my 1:20.3 layout. Those bridges that Scott made were for a 90 inch radius. He figured all the angles for each bridge and when I finished building them, they formed a perfect 90 inch radius. He even helped design the bridge sections to be able to attach the catwalks from Garden Metal Bridges. I have some pictures of those bridges somewhere…let me find them and I will post here :). I have been in contact with Scott within the last six months, wanting him to fabricate three large 1/8th scale water tanks for my Arrowhead Water Car in 1/8th scale! He can build anything and he will work with you on the designs. Paul Burch (a member here on Large Scale Central), has a few of Scott’s bridges on HIS layout! And those bridges have been there for well over 10-12 years in Pacific Northwest weather.

I found some photos of the "curved deck bridge “kits” for a 90 inch radius. Scott made these kits “custom” for me. I believe I have a total of 12-15 of these for a custom curve on my layout. Even made them to accept the Garden Metal Bridge catwalks! There is internal structure in each bridge for cross-ribbing detail. IIRC each bridge was less than $30.

He even made a few 24 inch long straight deck girder bridges for me and was in the process of sending me some samples of supports for the bridges. At that time, my layout was going to be ground level so the supports were much shorter. When I decided to elevate the layout, he was going to design some much taller supports (much like Diablo Trestle on the Cumbres & Toltec.

The photo below is one of the first set of bridges I got from Scott in mid 2011. He made four, 48 inch long “steel” arch bridges for a 16 ft. long arch bridge complex. Notice all the internal structure in these bridges. These were $100 apiece then, everything included. Rick’s arch bridge is larger version of THIS bridge.

Gary: Those look really great. On the drop girder bridges, what are those ties? Are they part of it somehow?

Rick: Are the bridge bearings included? That’s a nice detail.

Those ties are from the defunct Garden Metal Models and were listed as Combination Bridge Ties and Catwalk with a railing. I picked up 2 boxes (1’ea.) as they closed up shop. BECAUSE they lost their molds to the Chinese! Not a happy ending… (as I understand it)

Bummer. Maybe they could be 3D printed in ABS. Tie plates that actually hold the rails would be tricky, but rails could be spiked. It’s a nice looking product.

Yeah, I learned of them because folks were advising us to buy them up while we could. I found mine in a hobby shop long after most were gone.

Jerry has a very long “bridge” on his SC&M. It’s about 10-12’ long and made of an aluminum tube:

That photo shows about 1/2 of it. The concrete tower supports are dummies - added afterwards, and not needed although they don’t hurt! It is incredibly strong and could certainly accept a 40# Hudson, maybe with one or two supports.

I’ll ask him to chime in with some details of where it came from.

Eric Reuter said:

Gary: Those look really great. On the drop girder bridges, what are those ties? Are they part of it somehow?

Rick: Are the bridge bearings included? That’s a nice detail.

Like John C. said the ties are from Garden Metal Bridges. There are instructions in the box of ties telling you how to use them for “curved” and a single catwalk. He did lose his molds back then, but is back in business now. I believe he announced it a few months on LSC. He’s going to use a different manufacturing operation to once again produce these ties. About 5 or 6 years ago, he was selling off the remainder of his bridge/catwalk ties on eBay as a “Buy now”. Many of us stocked up big time and bought many boxes to have on hand “just in case”. If I don’t decide to continue on with 1:20.3 (because of my return to 1/8th ride-on scales), I might be willing to sell the 35-40 sets I have. They are all brand new and never opened.

I don’t know where Rick got his bearings (Rick is a Master Modeler, he probably made them!), but I bought a set of four castings from a company in Phoenix, AZ called Mainline Bridges. I just looked them up and at least he still has a website and he shows the bearing block available at $5/each (metal castings). He makes some beautiful welded metal bridges, pricey but awesome. He has metal catwalks for $50 per ft.!

Eric Reuter said:

Gary: Those look really great. On the drop girder bridges, what are those ties? Are they part of it somehow?

Rick: Are the bridge bearings included? That’s a nice detail.

Eric,

I built the bearing plates from heavy Styrene, they were made to pivot because the double bridge installation was on a slight grade,

I re-used them on the present install because it is on a 2% grade.

It would be nice to hear if they (Split Jaw) have improved the quality and strength of their bridge products since the only experience is from 9 or10 years ago. Gary I am not saying anything about your comments, I believe what you said. Just wondering if they changed/upgraded/beefed up their material. Looking at the S&J , it looks to be a great product and a decent price, I have a bridge or 2 I was going to make for my layout , but with these prices I think buying will be cheaper in the long run.

Pete, a little confused, I may be wrong, but I interpret Gary’s comments as on the J & S Railcars products. But you talk about changing the materials. That’s solid ABS, so are you looking at better than ABS?

The SJ (you put S&J) has material that looks to be like it would not be as sturdy as the solid ABS. (My opinion based on the look and what others have said about the SJ roadbed products, which seem to be some kind of structural foam)

Greg