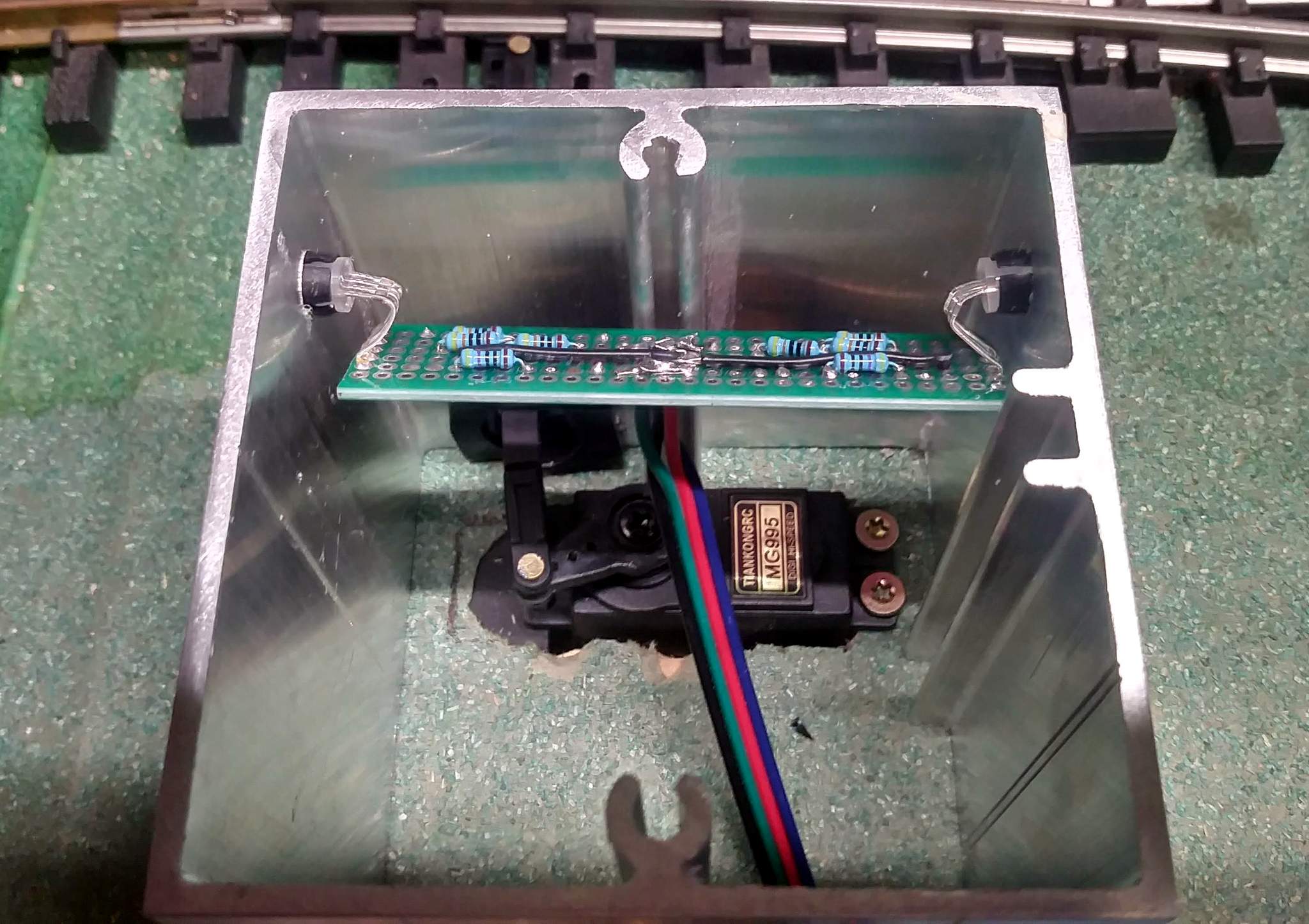

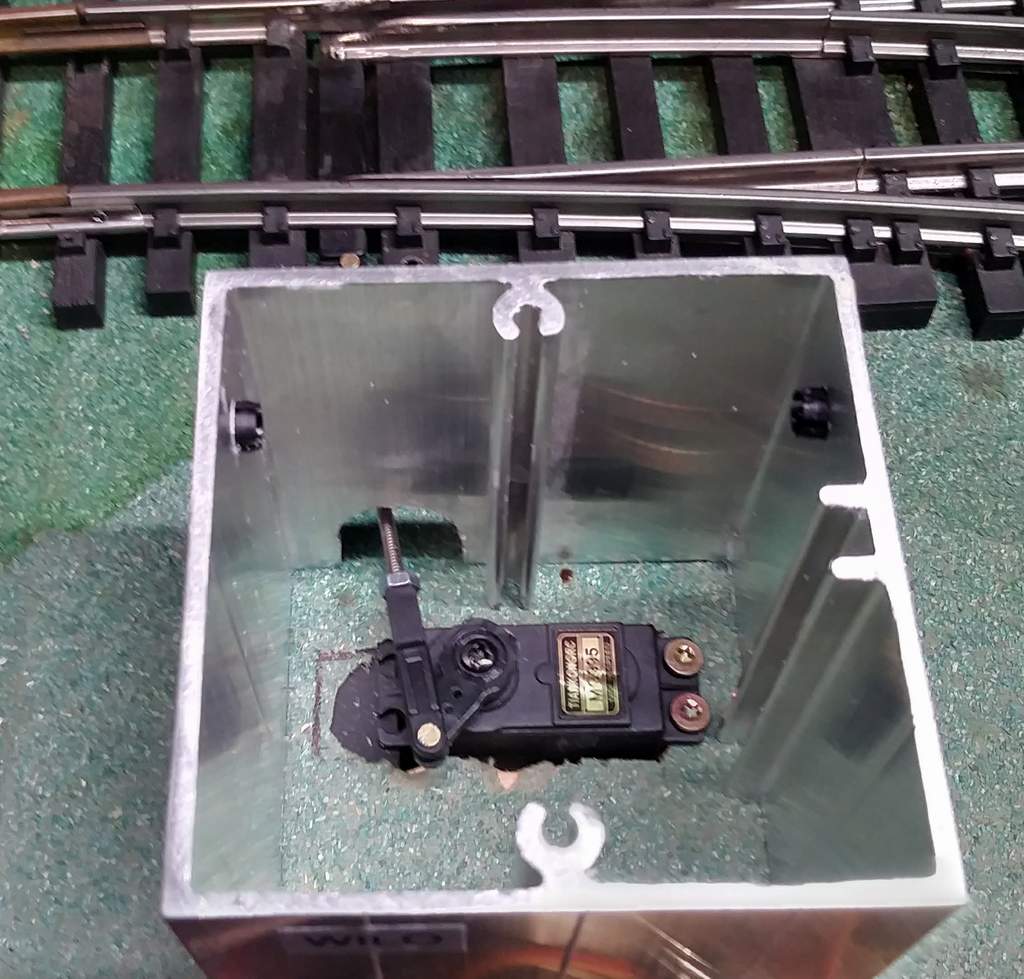

Today I started working on the modeling aspect of this project. The servos will be hidden by a generic “equipment cabinet”. Years ago I trimmed some 3.5" square aluminum post scraps to 3.5" cubes with this use in mind. Today, they were finally put to use. Looking at prototype photos for ideas, most of the aluminum ones are made from panels, so I scribbed in some vertical lines with 4 passes of a utility knife. I would really like the lines to be wider and deeper, but couldn’t come up with a better way with the tools I have. The cabinets were drilled for 5mm LED holders and an opening was made for the push rod. Here is the preliminary test placement…

I’ve not worked out what I am going to do for a roof. Simplest would be a piece of flat aluminum stock attached with screws to the C shaped extrusion. The prototype I looked at has a slightly pitched center peak roof. I could bend something at work on the brake that might work. Cutting the end gables would be the challenge. That, and nearly all of the aluminum sheet stock I have at work is painted white or black. I suppose a black roof might work.

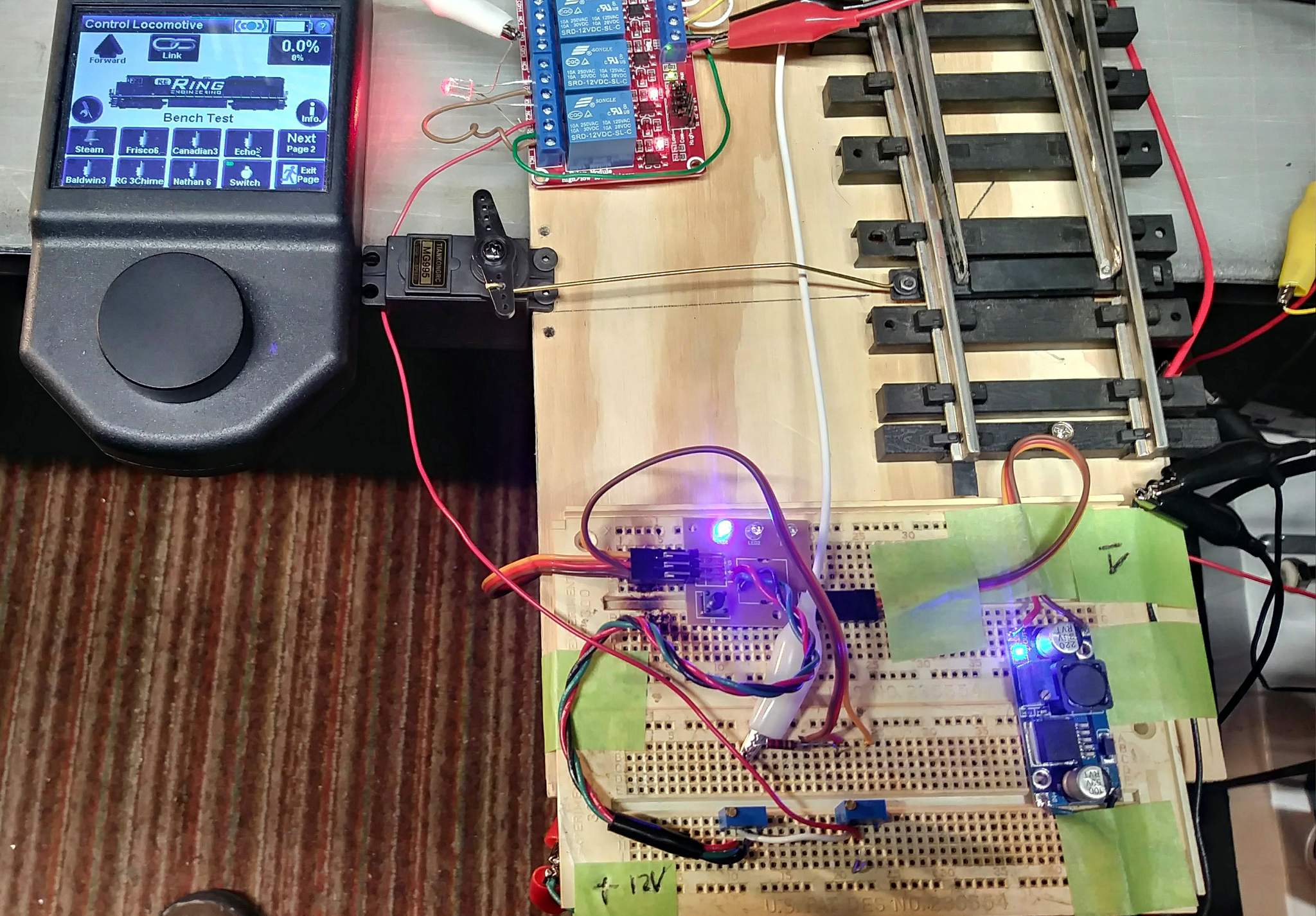

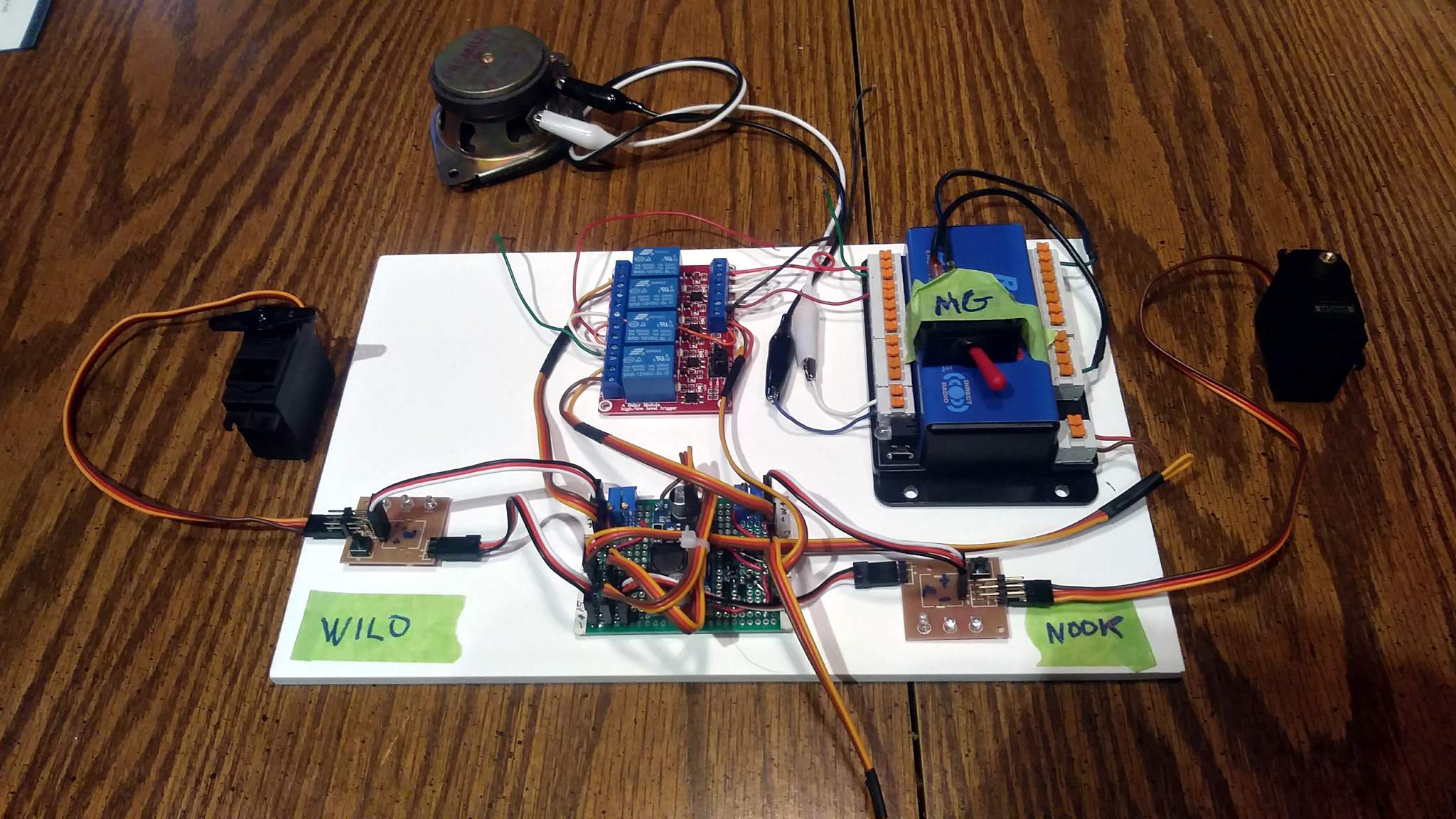

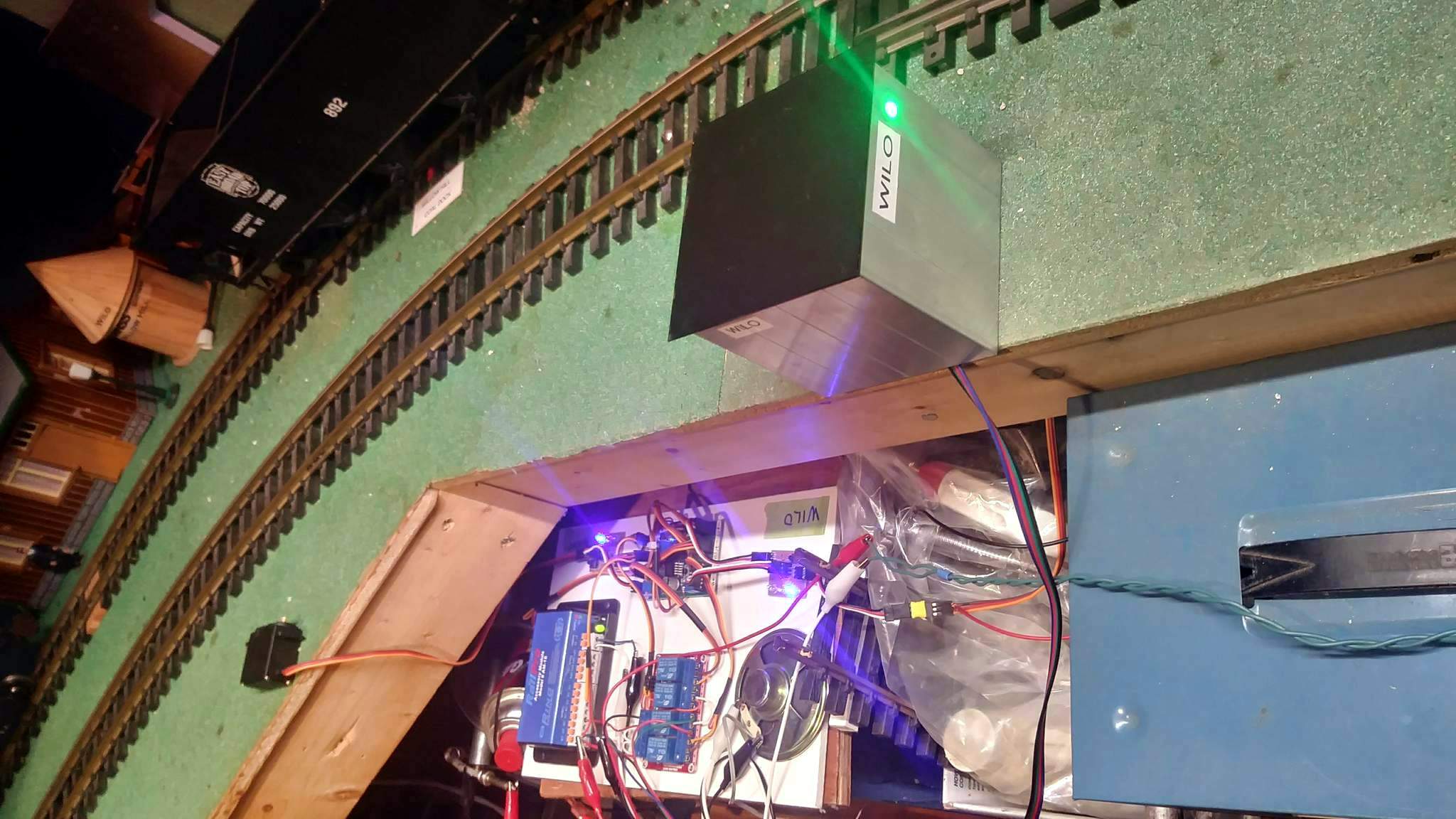

Next I soldered up a pair of RGB LEDs onto a multi conductor cable for the position indicators. These are wired to the relay board which has both N.O. and N.C. contacts for each relay. The default position (at power-up) is with the relay Open which sets the points to main-line and illuminates the green part of the LED. Shown here with M-10 doing the clearance test…

And another test with the switch thrown to the Willow Hill spur…

There is only one problem with the system defaulting to the main-line. The lift-out bridge just a foot or so away and might be open with just a manually placed peg being the only thing keeping a train from going into the abyss…

Fortunately, the RailPro system offers a solution. There are several inputs on the Accessory Module which can sense the position of an SPST switch. Their accessory programming logic allows for the state of an input to determine what action is (or is not) taken. I will be adding a SPST push button switch to the closure area of the bridge. I need to work out the exact program, but the theory is: If the bridge is down, allow the switch to be thrown to the main line. However, if the bridge is up, do not allow selection of the main line; move to and stay in the spur position until the bridge is down. I just need to work out and test the logic.

Another potential use for an input would be to sense a fascia mounted toggle switch used to throw the points if the hand controller isn’t handy. The logic for that might be a little tricky since it’s position will need to be ignored when the hand controller is used to throw the switch. Logic for this functionality is a bit hazy at the moment (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-surprised.gif)so it will be a future enhancement.