Hi all,

One of the issues with 3D printing for outdoor use is generally, the low melting temperatures or the instability of the plastic due to UV sensitivity.

The shop I buy my moulding supplies from also sells temperature resistant casting supplies generally designed for casting metals with low melting points.

Recently learnt that a local foundry was providing industrial casting services using a Lost-PLA technique. A web search has shown Lost-PLA casting can be scaled down for bronze or aluminium to create detailed miniatures. I recalled my father used to melt pot metal, pewter and lead (in the kitchen, no less).

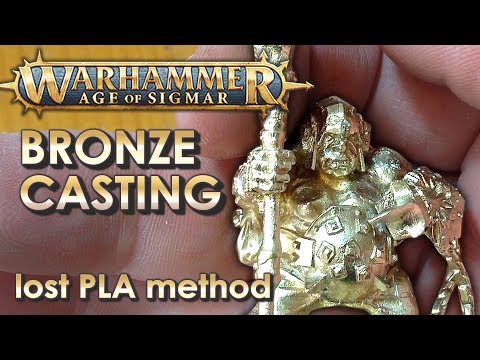

Here’s an example of what can be done if you have a forge:(you can skip to the end just to see the detail).

Has anyone here played with lost-PLA or Lost-resin casting to make things in pot metal?