Boy, what an impatient bunch. (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-smile.gif)Thanks for all the feedback. Now that summer has hit, there will be some breaks as I’ll be travelling a bit.

I am working hard on it. I’ll get another update complete over the weekend. It’s getting tedious with all the small details, so while progress might look slow, it’s not due to lack of work. It took an entire day to cut out and apply Burl’s hinges to the center section.

I made a trip to Roundhouse Sales in Edmonton last week and was saddened to discover that after 51 years they are closing their doors. Hobby shops are becoming a thing of the past. I scooped up $125.00 worth of brass rod for $37.00. (70% off).

Craig, are you talking about Aristcraft, or has somebody else gone out of business?

Sean will be happy to know that I’ve acquired some more green tape. (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

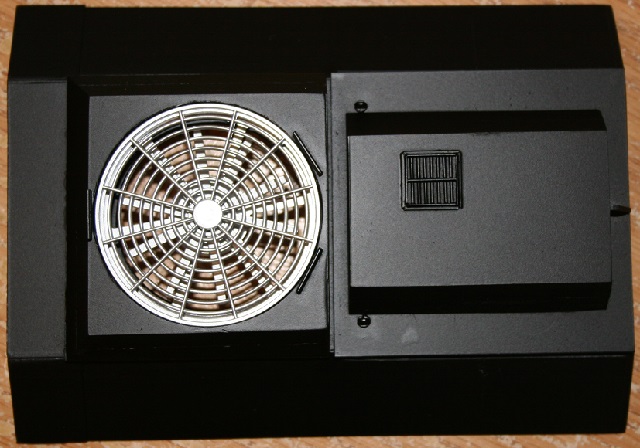

Here’s another teaser. I’ve ordered some screen that I hope will work for the tail end vents. Hopefully I’ll have it in a few weeks.