Just wanted to share some of my experiences using the Elegoo Mars SLA printer now that I’ve had some time to play with it. I’ve been printing FDM for 5+ years now and there is a bit of a learning curve when moving to SLA. You literally have to think upside down! Instead of gravity pushing down on the part it pulls it away from the build platform as it’s dipped in the vat of liquid resin and lifted up (also creating a bit of suction) with each layer. Therefore, careful attention must be paid to “suspend” rather than support but I’m getting the “hang” ![]() of it!

of it!

I’ve been playing around with the 3 seemingly most recommended resins for my printer and the clear winner is Siraya Tech BLU. https://www.siraya.tech/ It claims to be suitable for functional parts and specifically formulated for the low-cost LCD printers. I’m a Scot so I tried blending BLU with the cheaper standard elegoo resin in ratios 50/50 60/40 70/30 and 80/20 to see if I could save $$ but found that wasn’t worth it as 80/20 was the only acceptable blend and were talking BLU @ $50/kg and Elegoo Grey @ $37/kg

My basic test was done by twisting the bulkhead in each direction a bit (about a half inch). Straight Elegoo grey as well as the 50/50 and 50/40 blends crack like ribbon candy.

Siraya Tech makes an ABS-Like resin called “Fast” $35/kg that I find suitable for thicker parts that need not flex like the details I add to my wide cabs and GP40 conversion parts.

Over the next few months I will be conducting real-world outdoor exposure tests to see how they hold up in the Northeast.

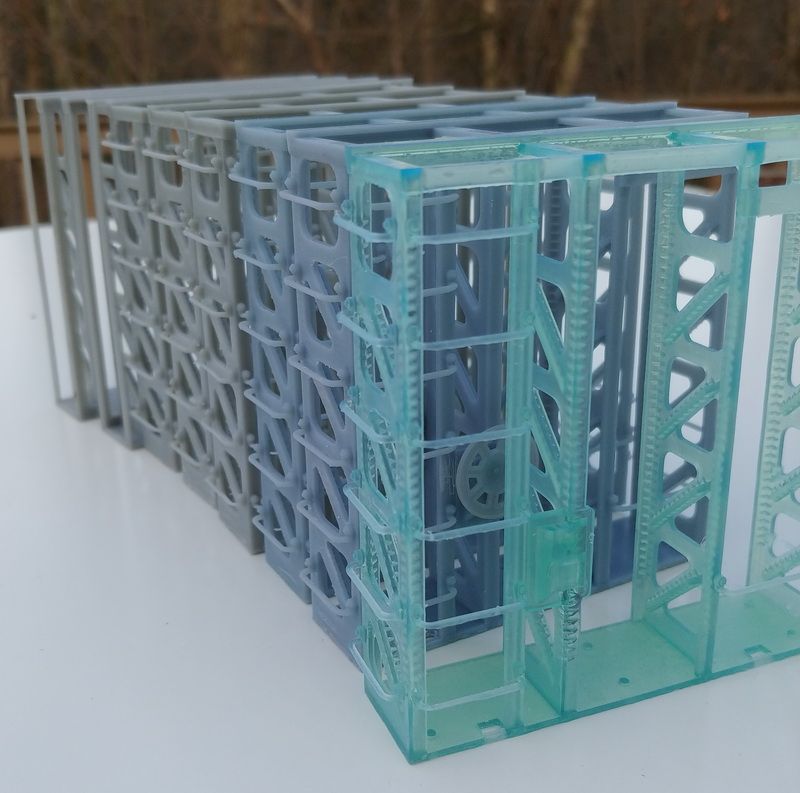

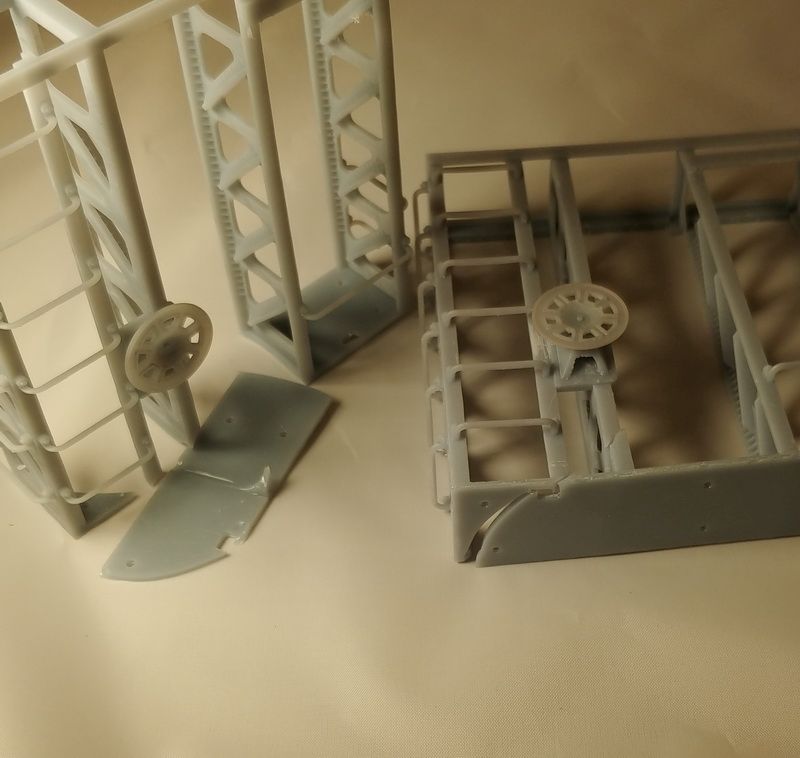

Some test pieces

Fails

BLU