Thanks for those insights, Rooster. I hadn’t considered running the cable into the unit, and maybe that’ll help.

However, the external coupling is the only means of releasing the bare cable through the various components, and the final means of fine adjustment. So, making a direct connection inside would imply a permanent (?) termination on the cable… but maybe not.

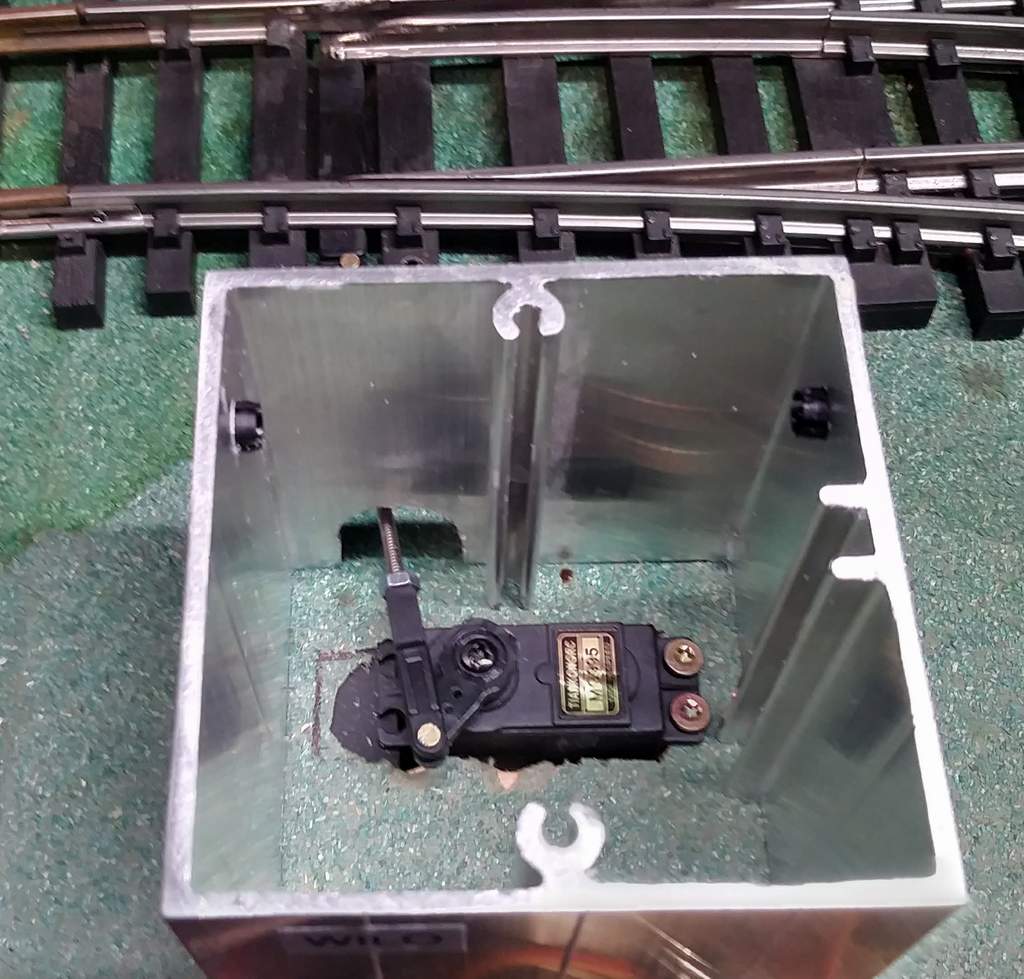

The BM stands sort of explode when you open them up, making reassembly on the layout, after making fine adjustments, kinda rough. But, again, I’ll think about it with all your suggestions in mind.

For now, I’ve put it all in a cardboard box, which is safely in my “Indiana Jones warehouse” of future / failed projects.

This is partially because after looking at my track plan, I’ll need at least 2 8’ remote cables, and that’s not gonna work with this cable arrangement: too much resistance. And way too much internal cable slop for the BM to overcome.

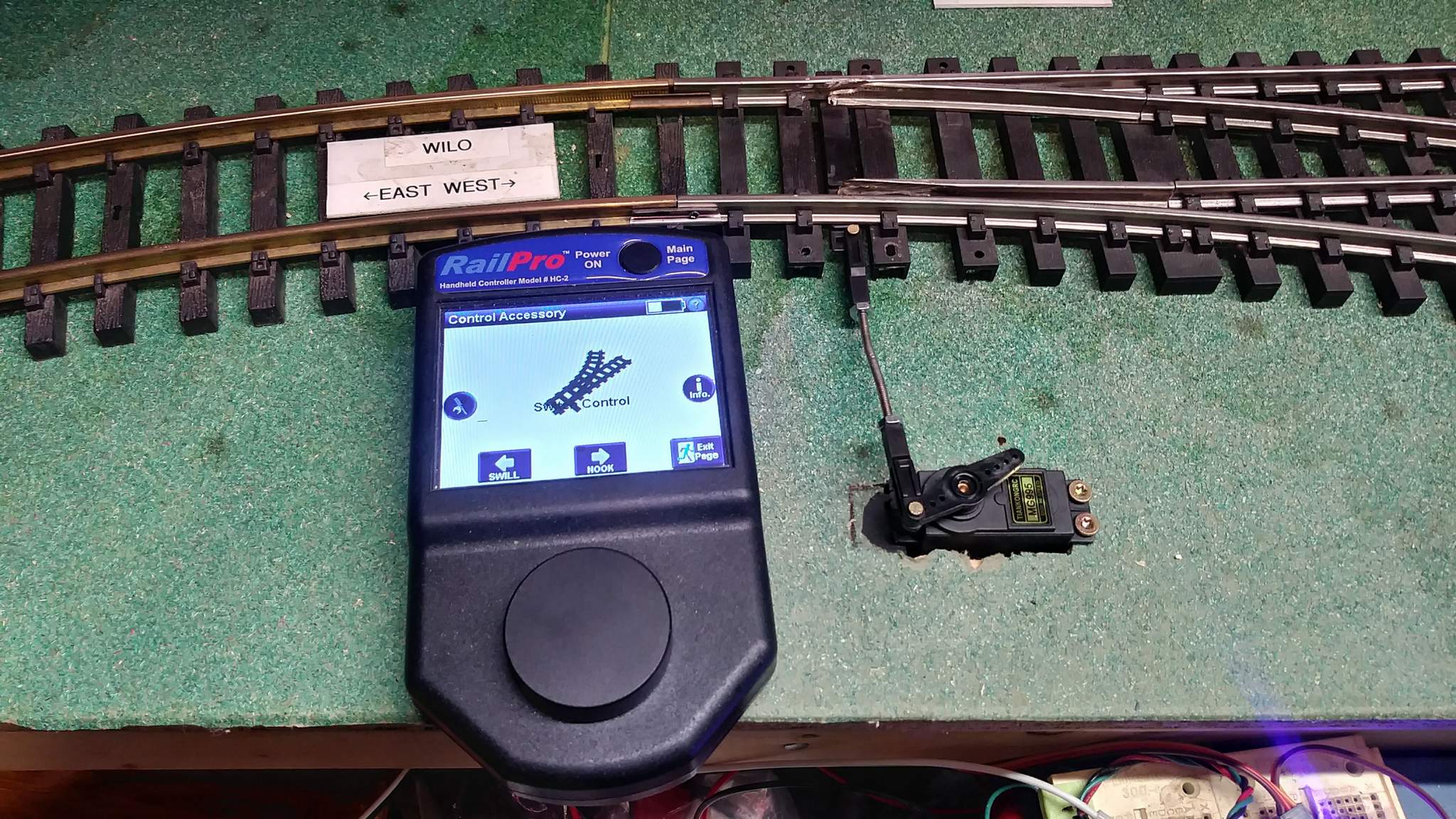

It’ll be far easier, now that I see all the issues here, to go back to my servo-actuated machine project, where there’s a local op button, and only an electrical cable needs to be strung to a remote waterproof pushbutton for actuation.

And Rick, if you think this manual adapter was over-complicated (and I can’t disagree), you ain’t seen nuthin yet!!