Hello all,

I recently bought my first G scale locomotive: a 1990s 2040 Crocodile by LGB. Previous owner had it on display on a rolling road for fifteen years and barely ran it, so it needs a little cleaning up and maintenance to get back to work.

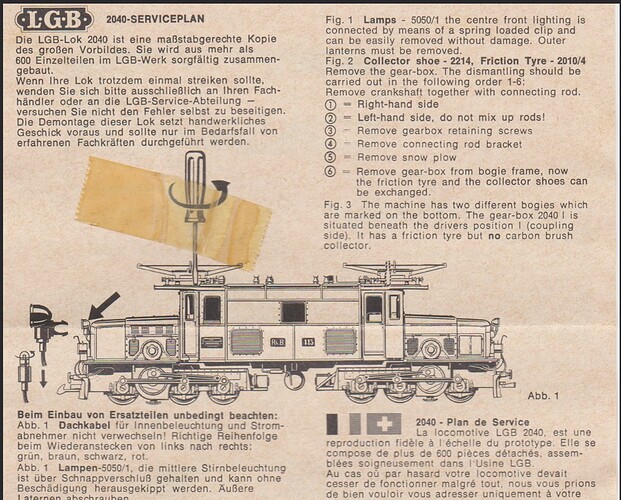

So, I decided to take it apart and do a deep dive into the insides. It’s in very good shape internally, and even had the original factory service manual with replacement fuse inside the main body! The only things that need addressing here are the pins that the doors are mounted too, since they’re starting to rust. I am thinking of replacing them with brass or stainless steel.

(I’d put a picture of the pile of parts here but I’m not allowed to embed more than one thing yet since I’m a new member.)

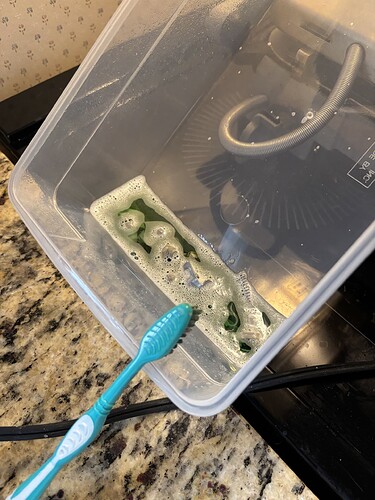

I took things apart until I was able to entirely remove the 2040-I motor block, which got disassembled and cleaned in warm soapy water to remove most of the old oil and grease. I don’t know if it’s an age thing or too much lube or both, but the whole assembly was slightly sticky.

After cleaning, the gears were re-lubed with a bit of Piko gear grease and the axles got a drop of oil. I discovered that one of the gray plastic crank arms is cracked, but not fully broken yet.

Three outstanding issues remain before I can put that end of the locomotive back together and repeat the process for the 2040-II motor block:

- No idea what the red wire is for. Blue and yellow run the motor, confirmed with my bench power supply, but red doesn’t seem to be involved. Must be something for the lights?

- The blue wire is frayed and down to a few strands where it’s soldered to the motor block. I don’t have a source for the old crimp connectors so I need to preserve this wire as much as possible. Easy enough to do with a solder sleeve and some new wire.

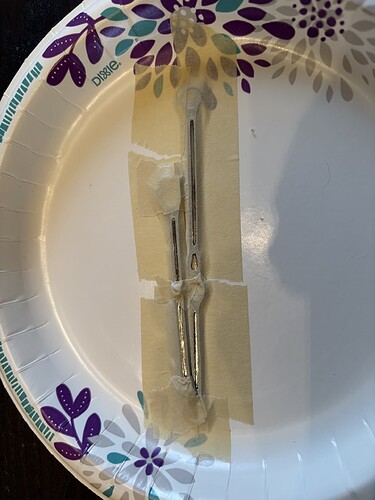

- Lastly, the side rods are in bad shape. They’re sticky and turning funny colors:

Does anybody have any recommendations for getting these back to their original shiny state? I’m comfortable with touching up the black paint accents if cleaning and restoration ends up removing them.