I’ve wondered how they do this…

Maybe 10 years ago I was riding the Cumbres and Toltec, and they kept putting the locomotive on the ground (at least a half dozen times). Got to see them do this a bunch of times. I have pictures somewhere. That was a very long trip (somewhere around 10 hours total)

So, 10 hours for the one RR trip, wow! Did they use similar equipment Bob?

I just saw this modern-day Euro re-rail system, pretty efficient.

What was the issue Bob? Bad loco or bad track?

Greg

Both, actually. It was in the era of “the track sucks” and a lot of it was soft. Combined with a recently rebuilt locomotive with too-stiff suspension. Kept popping off the rail. They rerailed using the wedge-shaped climbers.

It’s a lot easier with a Bachmann locomotive(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)

Fascinating! What a monumental job to rerail such a huge, heavy loco. Even the tools for the job are too big for a single man to carry!

Here’s when the “Modern, Model Railroaders” are way ahead in technology…

Most operating Model Railroads have developed the “Five or Ten Fingered Lift”, which if used properly, can usually re-rail an average locomotive in minutes/seconds.

The only safety instructions needed are…“Don’t over extend yourself, and strain your back”…!!

Fweddy

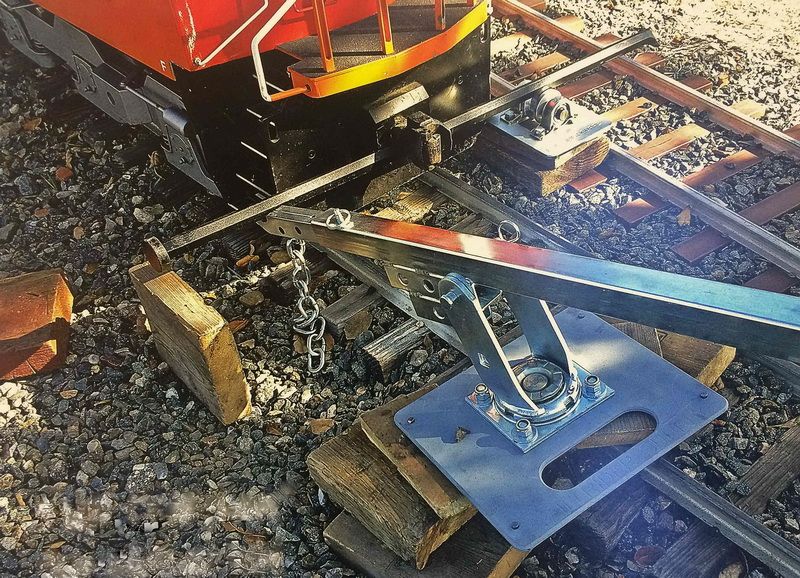

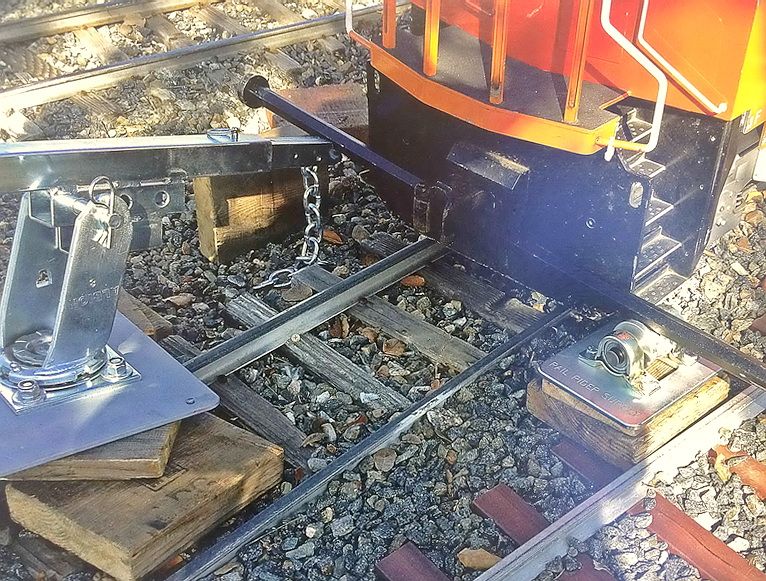

Here’s what we use in the “hernia” scales…Re-railing a 900 pound 1/8th scale diesel at Orange County Model Engineers in Costa Mesa, California.

Split a switch!

The “set-up”.

Re-railed and back on the track.

The Rail Rider/Dan O’Brien Re-Railer Kit.

My Rail Rider Re-Railer kit in use at home. With this kit, I can easily re-rail my 350 Baldwin Electrics or my 225 pound, 6 ft. steel gondola on my home 7.5 inch gauge layout (by myself) and not “break a sweat”.

Wow, those are some impressive model trains!

Give me a lever long enough and a fulcrum on which to place it, and I shall move the world.

-Archimedes

We’ve only had 315 on the ground twice. Once in Durango on the D&S, And once on the C&T. On the D&S it went inside the rails in the yard, and they just backed it up and it climbed back on the rails. about 10 min. total. On the C&T it went over one side at a bad joint in the yard, two wheels. Used the Frogs, ( thats what those heavy metal things that look like frog feet are called) and walked it back on in about 10 min. No Damage, no big deal. Thats railroading in 1:1 scale. I am glad that 315 is a smaller, lighter engine when it comes to that kind of stuff.

BTW: The C&T has spent several Million $ on track work in the last few years. Having driven most all of it recently, I can say that there is long sections ( most all of it ) that are at class 1 standards. I think that they are two seasons from completing a 6 year total rework. They have replaced tens of thousands of ties and re-ballasted 10’s of miles of road bed. Also as a direct result of great track, Loco and car maintenance has decreased. On the D&S they have started a major track work program of upgrading, bringing in outside contractors to assist their track crews.

While not steam, I’ve derailed a few,pieces of modern equipment. A few locomotives with wood pieces and a eye and ear for the MOW crew. One hand on the throttle, one hand on the brake.

Boxcar are easy too. Just throw a few scraps of wood under them and they pop back up.