Like this guys approach to modeling!

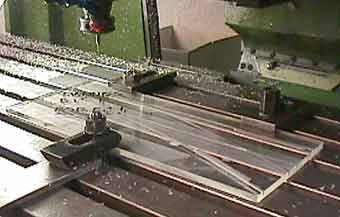

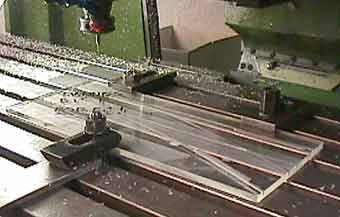

3d printed rails

I’m printing these buffers next to see how they do

his approach to turnouts is quite unusual

http://www.utj.se/ny_sida_08vaxlar.htm

Like this guys approach to modeling!

3d printed rails

I’m printing these buffers next to see how they do

his approach to turnouts is quite unusual

http://www.utj.se/ny_sida_08vaxlar.htm

Well , it’s clear he enjoys it .

Mike

Gave me an idea for an industrial siding i’m going to be working on, ran out of track, going to use this method to do the whole thing (roughly 20 feet long and 3 feet wide so about 4 lines)

Funny one Mike M.

I’m thinking that Lexan or plexi is a clever idea but not cheap. It is a pretty thick piece.

Mark maybe you should print up some bridge guard rails? They could be modular to accomadate different length spans ??

Got a laundry list of projects to finish, hope to have the Bombardier Bi Levels rolling by Nov 1 for the NYS Train show in Syracuse.

Then get the F40ph Kits available

Update the spines to 53’ all purpose

Work on the Alcos

Work on the Sharks (or Jerry is gonna kill me)

oh and to top that off I did this yesterday for giggles

(https://fbcdn-sphotos-a-a.akamaihd.net/hphotos-ak-xfp1/v/t1.0-9/10346308_10202781693611318_5940825929796376561_n.jpg?oh=bea4aaff865b2d544ab3493782fad24a&oe=54E3F4CE&gda=1424535211_dd2405ca248fe865a434c468dc888035)

Mark, and when are you going to have fun? It sounds like an awful lot of work to me.

Mark Dashnaw said:

Got a laundry list of projects to finish, hope to have the Bombardier Bi Levels rolling by Nov 1 for the NYS Train show in Syracuse.

Yep, don’t get distracted. ![]()

![]()

Now back to my program! ![]()

David, I have fun while the printer is printing, some of the Bombardier cars pieces take 6hrs a piece on the printer, lots of time to play in between, actually those pieces i send before bed and wake up to (hopefully) a clean printed item

I need no less than 3 of these please

http://thingiverse-production.s3.amazonaws.com/renders/64/d0/5f/fe/2d/DSC_0543_preview_featured.jpg

i’ll have to check his copyright info, they print out well

(https://fbcdn-sphotos-b-a.akamaihd.net/hphotos-ak-xpa1/v/t1.0-9/6264_10202782893161306_1837841613042448150_n.jpg?oh=3acb2ff05e73c78109ecc251e158edb2&oe=54F0716D&gda=1425531887_12e866fa0754c11f67b9ea080703df4f)

(https://fbcdn-sphotos-g-a.akamaihd.net/hphotos-ak-xap1/v/t1.0-9/1502519_10202782893081304_4504936055788224226_n.jpg?oh=22b00ae57ebe31322931419b1661f0b5&oe=54F0752F&gda=1424078102_e6ff1545bc639df6d0ecde21e794e69f)

(https://fbcdn-sphotos-g-a.akamaihd.net/hphotos-ak-xap1/v/t1.0-9/10519186_10202782893201307_7180357921365525799_n.jpg?oh=2e3467edf9bfe2630a7c7d4b5632974f&oe=54EE1225&gda=1424962672_779c05697924f04f0117181c1073ad90)

It would be quicker to make it out of brass----without the unnecessary rivets , and I would guess it would be more rigid too .

Sorry , but there is a limit to praising plastic ; it is better reserved for applications where it proves more cost effective .

Mike

Mike, since I don’t work in brass how long would this take you to make 1, or 2 or 3 and how much would the materials be?

Can you break down time frames from cutting the stock to assembly? Really curious as to how fast you can do something like this.

The plastic took 14g which cost 5cents a gram and it took 44 minutes to print, which for me was easy and mowed part of the lawn while waiting for the piece to print…

I did not intend to provoke an argument , I was just pointing out that there are other ways of doing the job .

If it suits you , make everything out of plastic , that’s your choice . For example , your carriages make sense , and gives a better utilisation of your machine ; setting up to produce carriage sides with the cutting out of windows in brass is not easy----your method is , (comparitively) .

It’s just that suddenly , wherever you look , someone is trying to sell machine printed models , yet nobody so far has come out with a life forecast for it . Ask the producer if the model can sit out in the sun and they go a bit coy .

As your bufferstop would become a nailed-down part of your real estate , how long before it reverts to a liquid ? See what I’m getting at ?

It’s horses for courses .

Mike

Not many people can answer the question of how long it will last, of course the plastic people tell us 500 years but I don’t buy that…

(https://fbcdn-sphotos-a-a.akamaihd.net/hphotos-ak-xpa1/v/t1.0-9/1560379_10202783306491639_4666397085877414651_n.jpg?oh=acc724c5e6e2ff2f18ee1c55efce6873&oe=54EB5514&gda=1424764286_0d1d1dff2aa4d648b00f587c79ea338f)

Took this photo on Wednesday. This has been outside 24/7 since July testing sun exposure to pla plastic

The front cab nose and roof held up fine so far, the long hood walls were a bit thin and with no internal braces have warped slightly. Still researching so that we will all know how they perform outside

I’m still really curious how long a buffer would take you to make in brass though…

And by thin i mean they are thinner then say usa trains or aristo walls btw…

Mark,

On that track bumper, that looks very European as in designed for twin buffers at the car ends.

The guy that made that is in Sweden, so that would makes sense,lol

It’s not my design its a thingiverse freebie file

Aha, don’t know my way around thingiverse, yet. ![]() As far as rigidity goes, I usually go with the proto’s samples of “cast in concrete”. That should be solid enough for most spots.

As far as rigidity goes, I usually go with the proto’s samples of “cast in concrete”. That should be solid enough for most spots.

Mark Dashnaw said:

The guy that made that is in Sweden, so that would makes sense,lol

It’s not my design its a thingiverse freebie file

if i was to do one to sell i’d think i’d go more american like this one

(https://thingiverse-production.s3.amazonaws.com/renders/a0/00/c6/c5/5c/IMG_2713_preview_featured.jpg)

Yes, that’s a better idea.