The thread showing “aging” of aluminum rail got me to thinking about doing the same to brass…I’m tired of waiting for nature to take it’s course and turn my brass rail that nice weathered brown. As a stained glass artist I have a fair amount of chemical “patinas” so I thought I’d play with them a little and see what happens. Test on a piece of LGB brass rail, light application of 50:50 “Bright Copper” and “Black” Novacan (Brand name) lead/solder patina gave me this… .

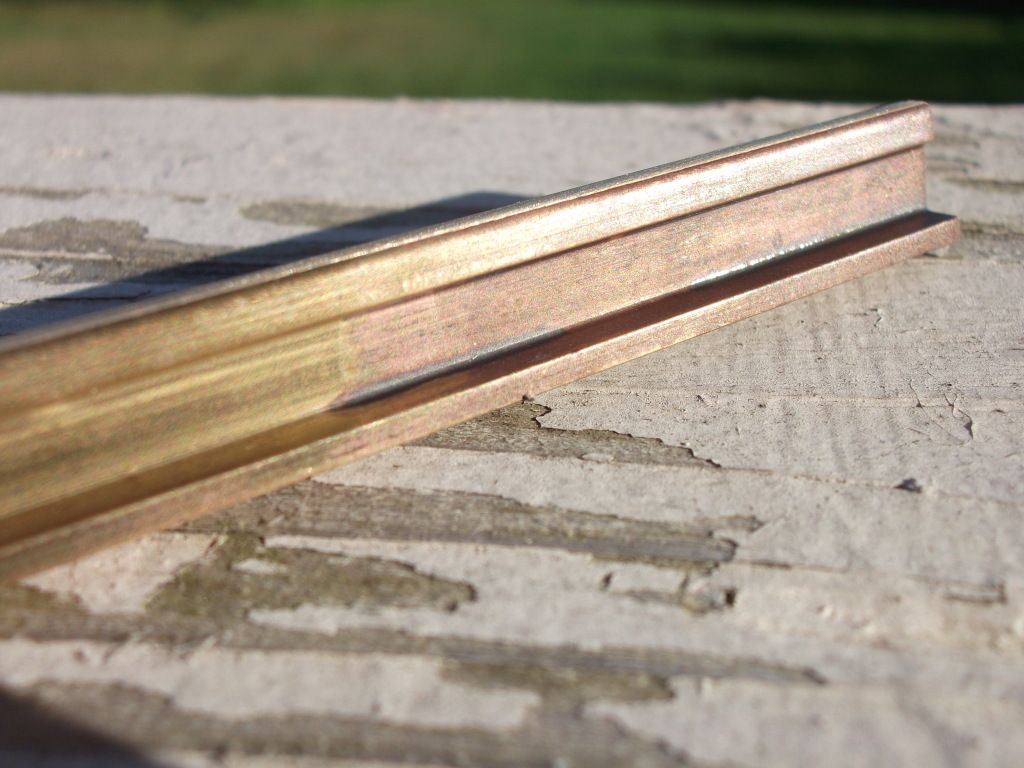

. . A longer application gave me this… . .

. . I’m not sure if I am going to do this on my layout or not. It took a fair amount of material and seems to work best on clean rail. I also do not like the idea of that much “acid” being applied outdoors to run into the ground or sit on my plastic ties. I’ll play with the mixtures a bit more and leave a section out over the winter…We’ll see what it looks like in the spring. Had I thought of this before laying the track I would certainly have done it on the bench.