Next project? I hope your not planning on 3D printing the whole thing. Looking forward to the build.

But, that there boxcar aint got no doors.

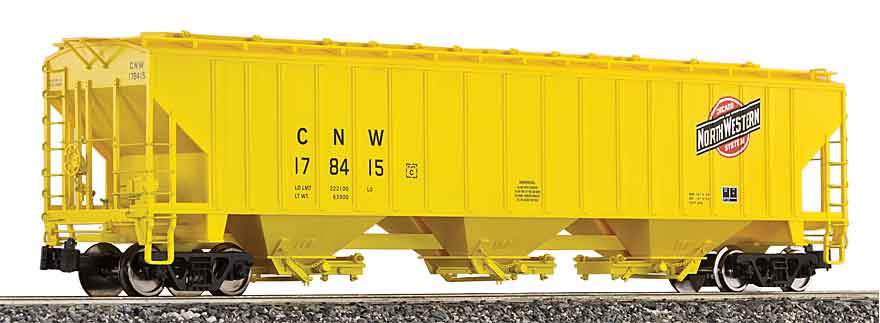

Let’s see how many people can spot the differences between the PS4427 and the PS 4750 that AML made…

I know, I know. One’s yellow and the other is red, right? LOL

Another difference is that one is Santa Fe and the other is Northwestern. Too obvious?

The ladder thingys are different, too. So are the “ribs.” The mechanism for opening the “drains” are different. One has a body mount coupler, the other has a “Talgo.” The Northwestern one has a curved roof, the Santa Fe has a flat roof.

How’m I doin’?

End beam is moved up, but at least it has one, I keep seeing boxcars with out end beams.

Burl Rice said:

I don’t think we can ask if it’s done yet… Burl …are you already done and this is the finished photo?

Your work and 1:1 are hard to tell apart!

Metal wheels are to rust free… No dirt yet!

I’m posting some more photos before I weather it.

Some pre-paint photos:

(http://burlrice.com/_LS_PS2CD4427/left_lr.jpg)

(http://burlrice.com/_LS_PS2CD4427/b_end_mid_lr.jpg)

(http://burlrice.com/_LS_PS2CD4427/b_end_low_lr.jpg)

(http://burlrice.com/_LS_PS2CD4427/b_end_high_lr.jpg)

(http://burlrice.com/_LS_PS2CD4427/3_4ths_lr.jpg)

An out-take from the “builder’s photo” shoot:

Outstanding. I’d love to see some more details of construction. Very fine work.

Very Nice. Very Nice Indeed. Do you have drawings of the car you are willing to share? What all is printed on this car?

I worked from drawings that were published in Mainline Modeler.

Everything in dead white is 3d printed nylon. Tan/off-white is resin. The bolsters, coupler pockets, and AB gear were 3d printed in acrylic (higher res) which I used to make molds for resin casting. The roof hatch patterns were also printed in nylon - I preferred the rougher texture for those.

I will work on getting more construction photos up later.

Burl Rice said:

I worked from drawings that were published in Mainline Modeler.

Everything in dead white is 3d printed nylon. Tan/off-white is resin. The bolsters, coupler pockets, and AB gear were 3d printed in acrylic (higher res) which I used to make molds for resin casting. The roof hatch patterns were also printed in nylon - I preferred the rougher texture for those.

I will work on getting more construction photos up later.

Burl,

Any chance I (we) can convince you to ‘sell’ via Shapeways the 3D prints of the bolsters, and coupler pockets?

I suppose I could, but considering they cost $40 (my cost) each to print, I hadn’t thought there would be much interest.

I cannot say that $40 would dissuade me from purchasing the parts. I am still exploring what 3D printer I wish to purchase for my modelling. I have seen the prices on Shapeways, and for as much as I want to model, purchasing my own makes sense!

When I drew the bolster and coupler pocket, it was all one piece. Since I designed it to be a pattern for mold making, I drew it hollow. I have my concerns about how it would hold up in a finished model. To print it solid, it would almost double the price, unless you intend to mold & cast yourself.

I had thought about buying my own printer too, but I resisted the urge and did several prints with shapeways, in various media, to figure out what would work for me. When the market becomes affordable for high-res acrylic printers, I might reconsider, but for now I’m alright with outsourcing. Right now, I’m doing a lot in nylon, and those printers have 6 or 7 digit price tags.

Burl Rice said:

When I drew the bolster and coupler pocket, it was all one piece. Since I designed it to be a pattern for mold making, I drew it hollow.

I’d be interested in the coupler pocket if you could separate the coupler pocket drawing from the bolster. If not I’d print off, and cast what I need. I should backchannel you about some questions… I’m drawing up a GN Snow Dozer in Sketchup to have some parts printed (coupler pocket/draft gear is one of the areas I was thinking might be a good piece to have printed off).

All I can say is WOW. This technology is really coming of age quickly.

Here are all the major resin components (except AB parts). I have tried to make this as easy to assemble as possible.