Project #3 is a part-finished UK teak coach, which needs glazing and lots of outside beading. As my LNER B1 is stuck in MD and I have nowhere to run a beast like that in Florida, it has been relegated to being a Spring job.

So on to Project #4, the LGB2018D Mogul made in to a Mason Bogie:

When I inquired, I was told there was a UK guy who put these together. Nice brass chassis, delightful cab, a 6-wheel truck from combining 2 x 4-wheel trucks, and a central pivot for the boiler. The loco behind is a proper Fn3 model of a Mason, made by Rishon many years ago. The LGB 2018D is a bit bigger.

The loco has been sitting since 2022, before hurricane Ian halted all work in my condo. Before that time I acquired a spare wooden cab and a proper 6-wheel truck kit, left over from the MLS Mason Bogie class. I think they came from our BD (@rmccown-admin). I did build the truck and installed it.

However, you’ll note the “DSP&PRR” in that early photo. Whoever made it used the whole tender which threw off the proportions, so I had cut down the frame and mounted the truck. I cut the old tender down on my mini table saw. Here’s how it looked when I moved in a few weeks ago.

The spare tender had been acquired last year as a replacement for the side that I cut at the wrong place. This time I plan to have DSP&P on both sides!

You’ll also note the droop of the smokebox. The Mason has a pivoting frame, so there is no smokebox saddle to support it. A final solution has not been found.

What I did find was a plethora (!) of wires, most of which I removed. Many had connectors, except for some unknown reason the wires to the headlight. So the first task was to add a connector so the whole smokebox could be put to one side.

You might notice the brass plate inside the boiler. That’s the ‘floor’ for the battery pack - the pink 18650s visible in the prior pic.

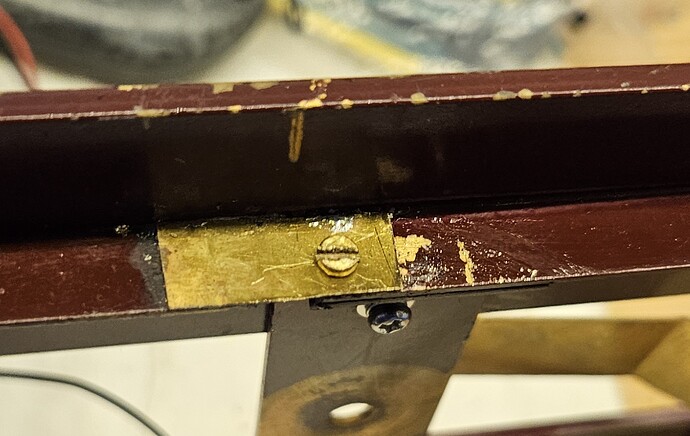

I found a bad solder joint in the modified frame, so that’s next. Then new paint on the frame and chopping of the tender.