I started this thread over on MLS, figured I’d post it here as well. A little background. I have a LGB sumpter Valley Mallet that I conerted to a smallish 1:20 mallet. But, I was never a fan of oil burners so I set out to convert the tender to a coal load. I’m gonna try Kevin Strong’s technique of making a removble coal load. Here is what it pretty much looked like to start. (i admit i forgot to take a before picture)

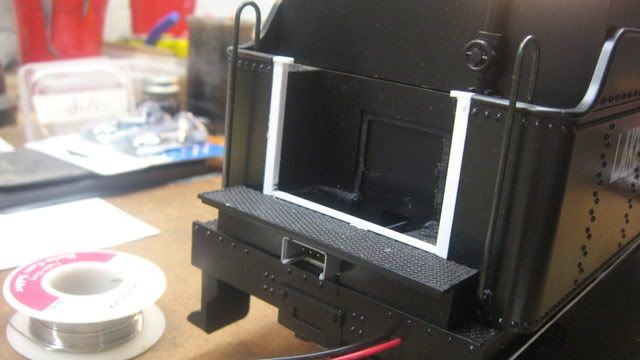

Front frame

Testing the fit of the boards

Overall pic. The slide switches are for frequency settings on the Airwire. The silver Jacks are for battery charging, the gold jack is for the phoenix P5 interface.

Everything installed and painted, boardsinstalled.

Closeup of the back. It always amazes me how a camera highlights dust an dirt…

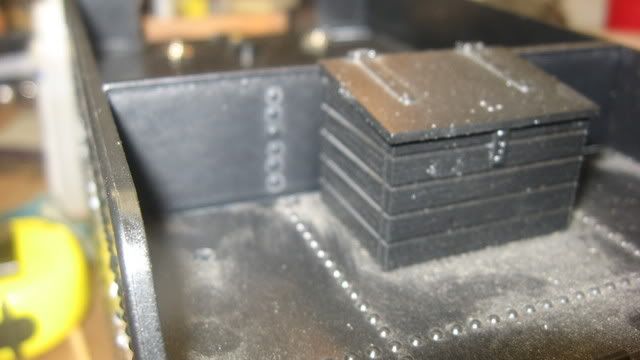

Laying the groundwork for the removable coal load. Thanks again for the idea Kevin.

The Glue drying pretty much bogged e down for awhile, so I’m gonna work on another project. I’ll post pics on that to. I’ll post more pics as I make progress. Terry