I have several locations on my indoor railroad that have manual switch machines that are out of easy reach. While building the expansion of Willow Hill this winter I decided to try a twist on the Choke Cable throw. I’m not knocking what Fred and Crew have done up on the I.P.P.&W., but I wanted something that worked a little smoother and used a ‘scale’ machine. I’ve had a little exposure to RC airplanes and thought that the tried and true method to attach control surfaces to servos would work well for switches. It took some trial and error but in the end it works flawlessly.

I began my quest at the local hobby store. He had this carbon fiber control rod set in stock. One factory sealed and one missing parts. I bought the sealed one and he threw in the open one for free. This is a common brand name in the RC plane game, so they should be available most anywhere…

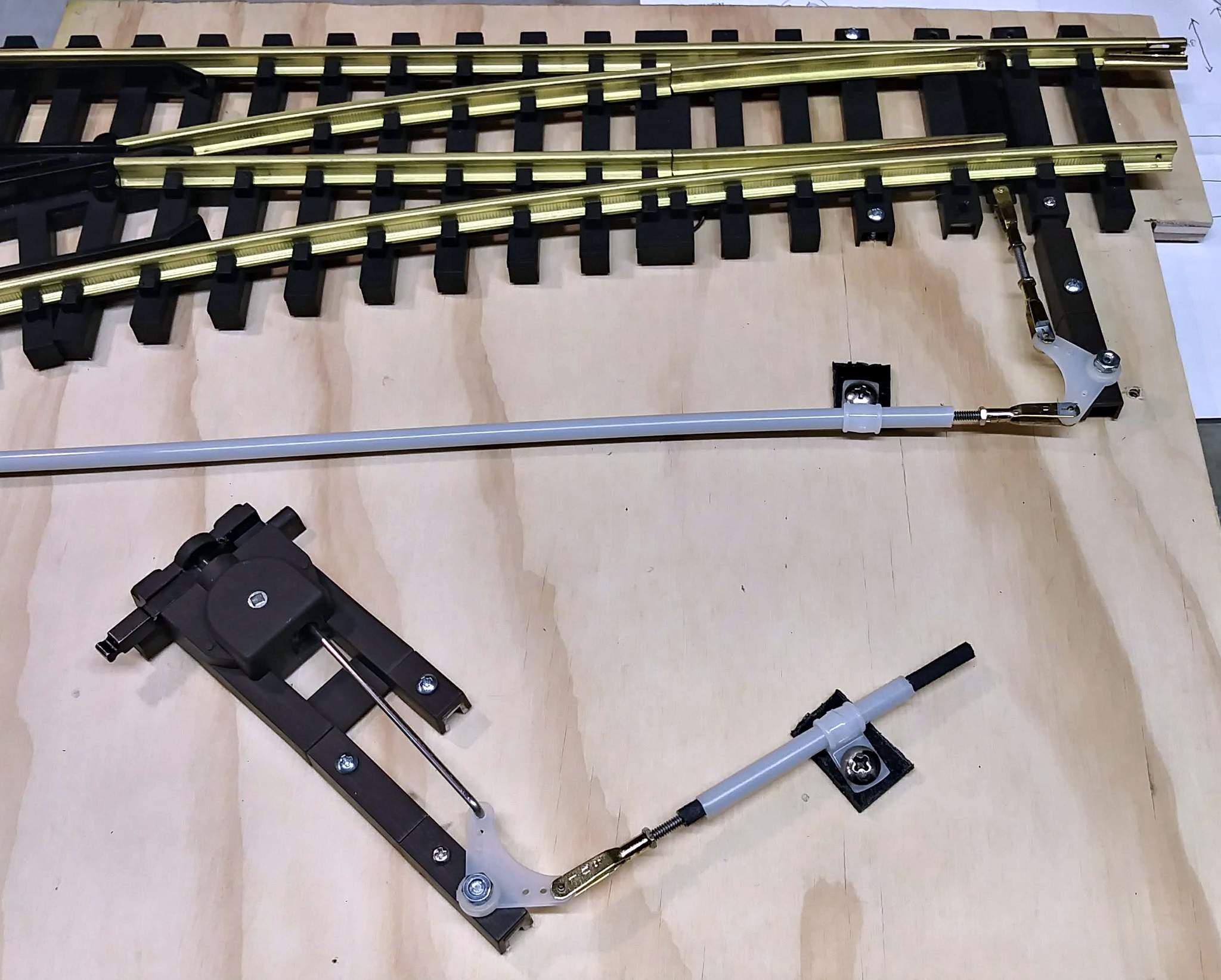

I experimented with home-made bell cranks made from hardware corner reinforcements, but operation wasn’t smooth enough for me so I put another $3 in the budget an picked up a couple of bags of the Dubro 90 degree Bell Cranks - Part #DUB167…

I am also using Bachmann Large Scale switch throws which work great. I’m going to be hunting for more at the ECLSTS this week.

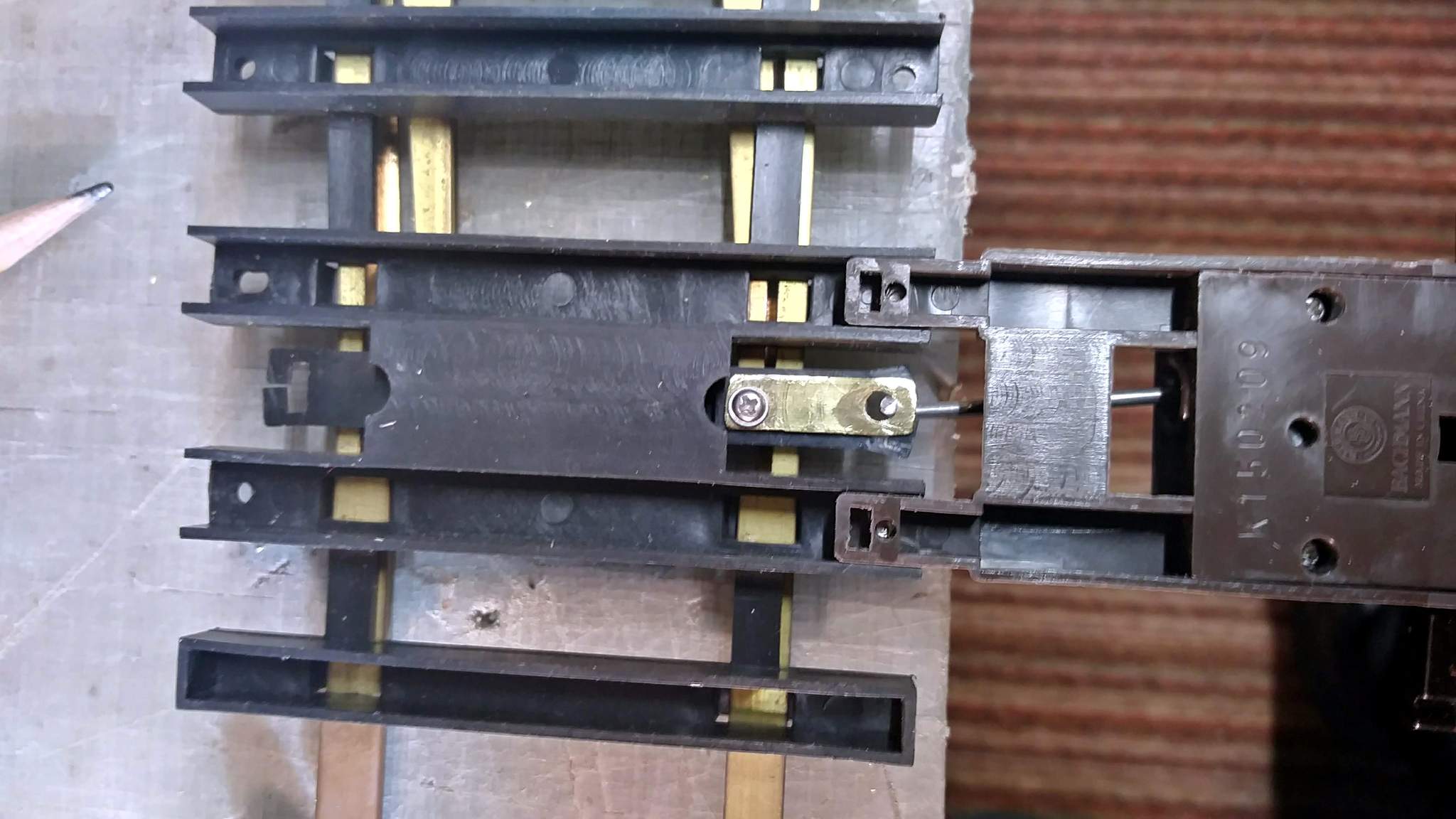

The switch I chose had a broken throw bar, so the first step was to repair and reinforce it with a small brass strip drilled to fit…

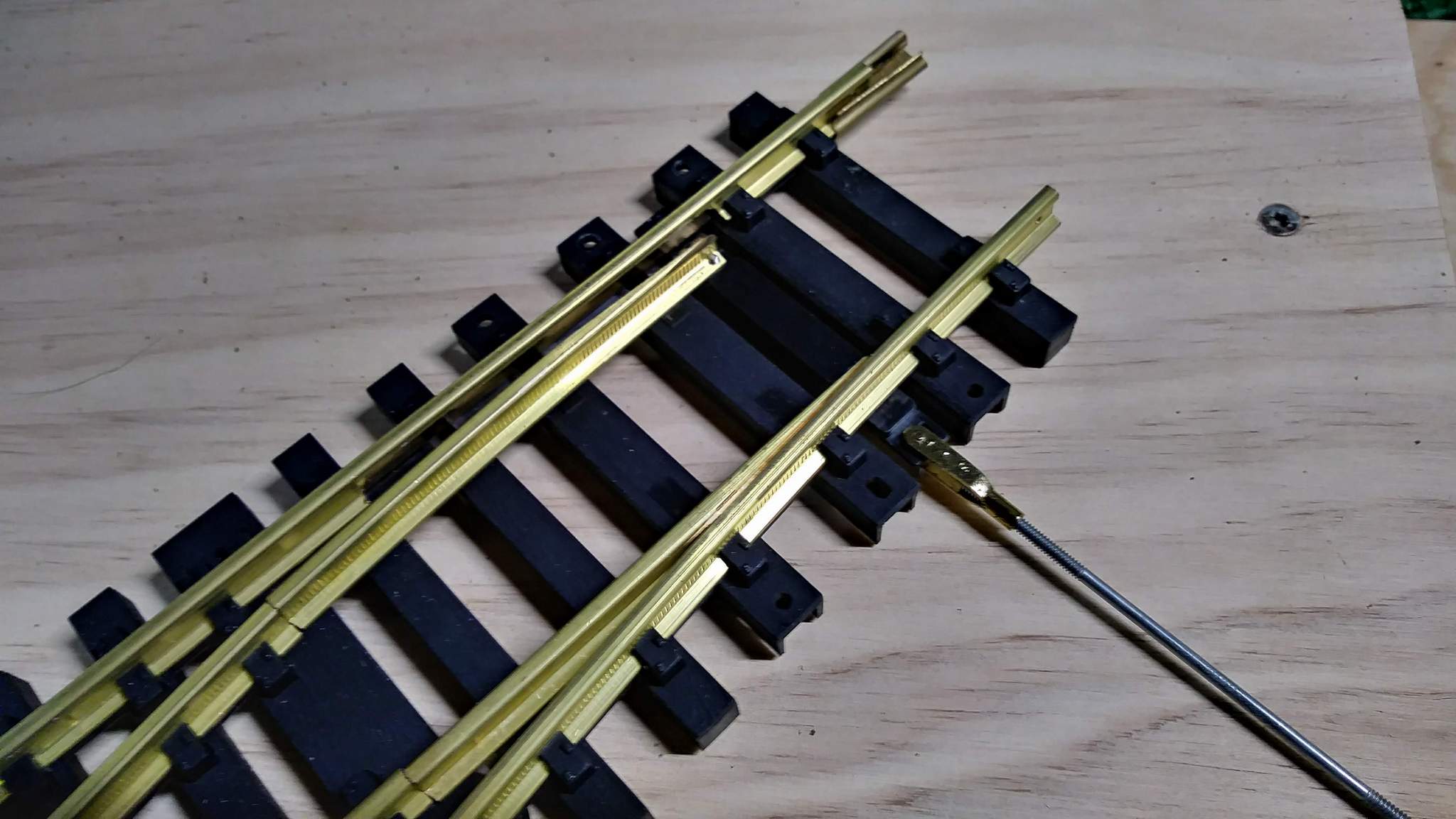

The machine was removed and a brass clevis that was included with the rod was attached to the throw bar with the included solid rod…

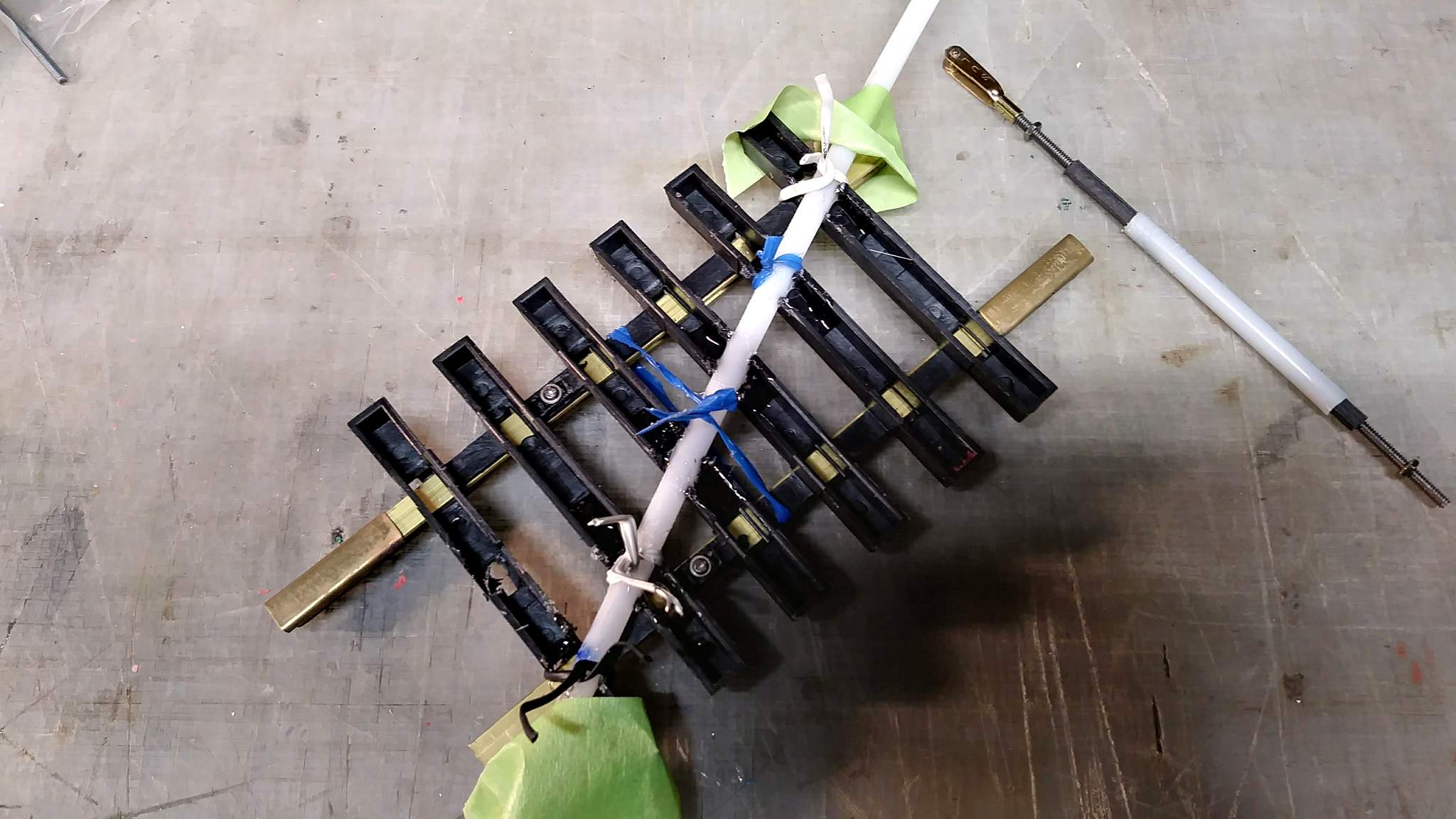

In my application, the rod will need to pass under a track, so the ties were notched out and the rod cover glued in place with E2000. The tape and bread ties are to hold the cover while the glue cures…

While the glue was curing, I set up a breadboard for testing on a small piece of plywood, attached a switch, and started playing…

The above test was purely to prove theory and required some changes before I realized smooth operation. As soon as the new bench work was ready, the switch was placed for operational testing. I needed to work out some issues of uneven throw which were directly related to not mirroring the angles created by the bell cranks. Once I got that sorted out the throw worked great. Here are some early shots just after tweaking was complete…

I would rather not have the machines so close together, but fixing that would require taking it all apart for the third time to shorten the outer cover and the rod. I got lazy, filled that gap in the track, and called it done…

Now that it’s done and has proven very useful during operations. I have several other places where this method would help. Installing more of these is on the agenda! I might also think about using the same method for a tall mount outdoors for ground switches.