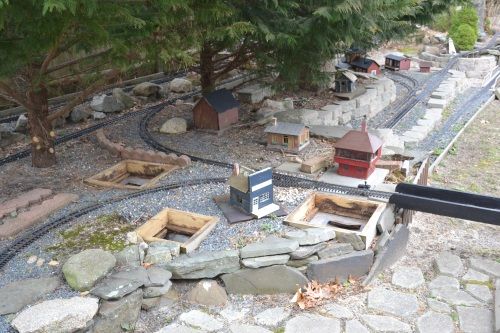

Well it was a good run of 10 years but the roof of “pinch point” tunnel has failed and trains are not allowed to enter it. The tunnel was constructed using cement blocks and a gravel floor around 5’ diameter track that was staked into the ground and a track power line was attached to it. The tunnel is nearly 15’ long which required 3 hatches to be installed. The roof of the tunnel was an odd shaped horseshoe so I used 2 sheets of plywood that were sandwiched together for strength, painted and then wrapped in plastic. As we all know water will eventually find a way in and that has caused the plywood to rot. The WYE on top came at a later date and the leg over the removable girder bridge leads to the main yard.

As you can see replacing this tunnel is going to be a big job but it has to get done. My plan is to take up the plywood, remove the cement blocks for reuse and instead of reusing the 5’ track that has created a problem on the RR, hence the “pinch point tunnel” moniker, I will use a 6.5’ curve. I would really like to squeeze a 8’ diameter curve in there but I don’t have the room. To the side of the girder bridge is a deck. I will rebuild the tunnel using the cement blocks and then I will cement the floor. The gravel that was in there seemed like a good idea at the time but over the years different critters have gotten in to dig around causing derailments.

My big question is what to use for the new roof? I’m thinking about cement board and cutting holes in it then use plastic trim wood that is glued to it to create the “chimneys” for the access hatches.

Today I have longer equipment like the DoodleBigger and my 250 ton crane that has a long overhang that rubs on the walls of the tunnel so I will also plan for that but how strong is cement board meaning how much of it can be unsupported and still allow 200 pounds to stand on it?

What do you think? How would you approach this project? Thanks.