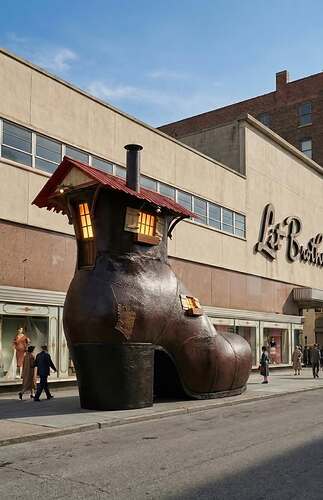

Progress continues on the Boot.

I was struggling in deciding how to attach the motor block to the boot and I came up with making a metal bracket. the rear will be bolted through the heel and the front will be screwed into the sole making nice and solid but still removable.

I’m still thinking about the cab and used a piece of thin plexi to make a windshield. I used a piece of postcard paper to make a pattern, cut it out on the plexi, found a can that was close to the curve of the boot, clamped one side to the can and used a heat gun to bend.

The plan is to attach the windshield and the side glass to the boot and then build up around the pieces with the air dry clay.

I drilled holes in the back of the boot and put LED lights in. For the front I wanted headlight housings but how to make them? I thought of using a pipe, hose or even a straw but didn’t have anything that would accept the big 5mm LED bulbs. I then thought of using electric wing nuts. I carefully drilled one out starting small and working up to the size required. Drilling a big hole in the rubber boot is not easy so then a lightbulb went off and instead of drilling I would melt a hole using an old solder gun with a round tip. Note to self, don’t do that again indoors, melting rubber STINKS!

I will paint the inside of the nut silver, hot glue the LED in with a dab and then press the assembly into the melted hole. Paint for the exposed edges will come later.