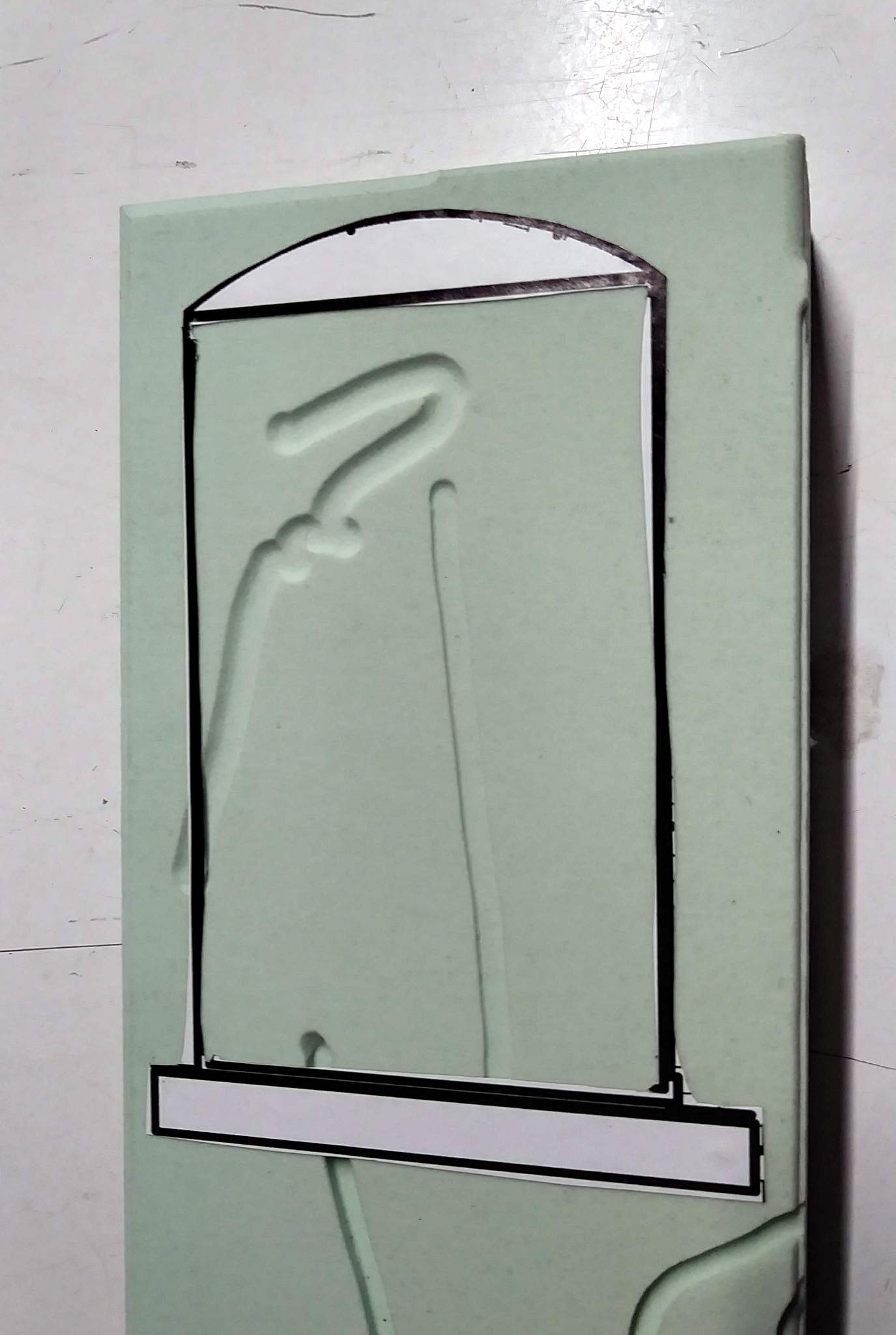

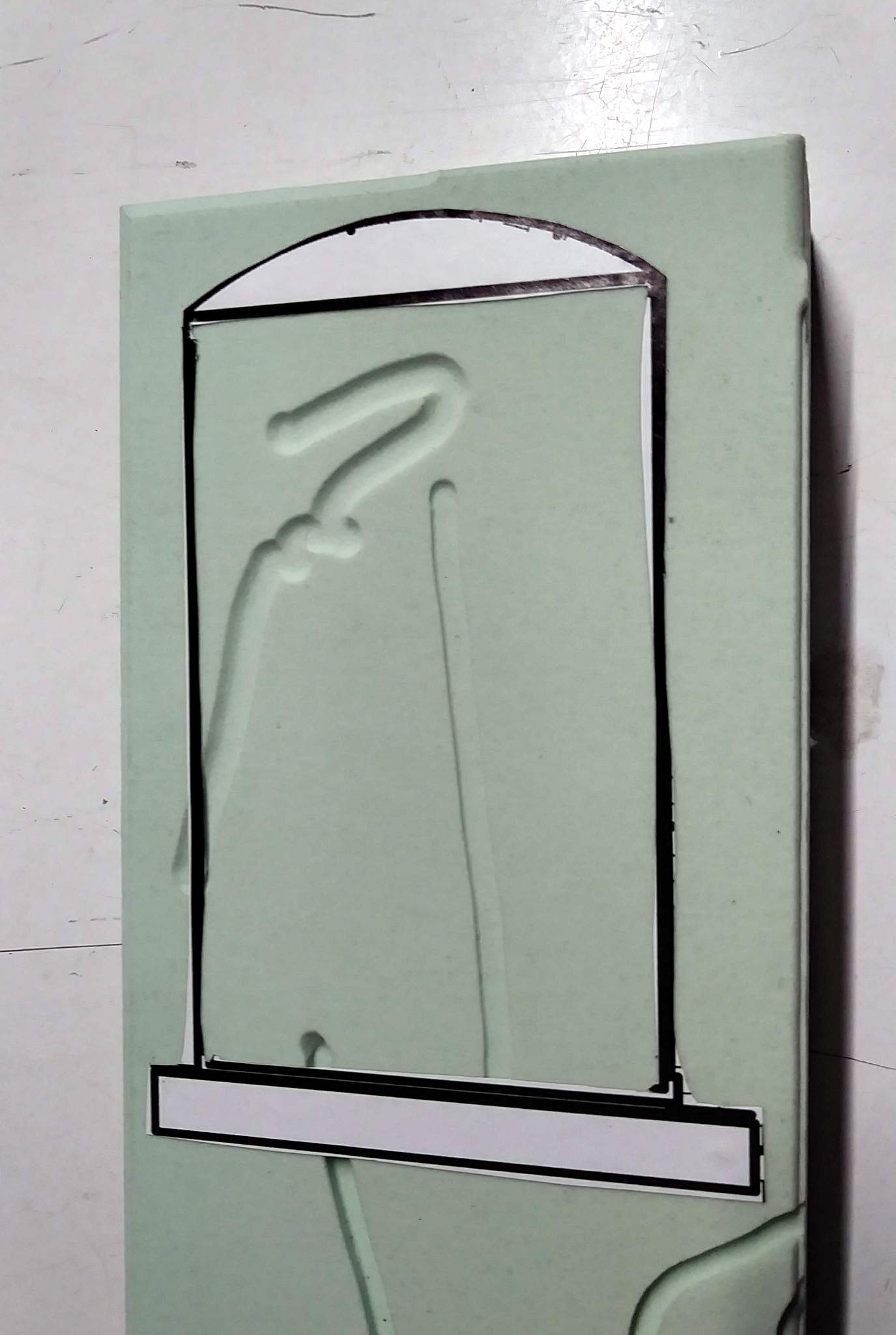

Rick Marty has been a source of inspiration to me for a long while. And Sean mentioned Ray Dunakin - You might see some of his painting ideas in this batch from the experimental kitchen. Testing window cutting. First the vinyl cut pattern is applied and the center removed…

Used a jigsaw to cut inside the lines as best I could. Cleaned up a bit with files then ran the Dremel router around the hole to shape the inside edge. I got hung up in some of the bad cuts…

Did better on the other side…

Paint and weather experiment…

The plain color at left is acrylic house paint in a Red Brick color. The base color of the arch is another acrylic house paint in a dark grey. Over top a very stiff and dry brush streaked on gloss white acrylic. Over top a wash with India ink & denatured alcohol until the gloss dulled up. Brick was done with the gloss white as a base, then I attempted to pad roll the red brick color. First pass was great then I made the mistake of hitting it again which put on too much paint and a lot of it dripped into the cracks. A liberal India Ink Alcohol wash including some scrubbing with a paper towel until I liked the color. When it dried it was too glossy so I sprayed it with an acrylic matte clear, but even that looks too glossy to me. After the contest I might seek out a can of the Dead Flat I’ve heard tell of.

Quite unlikely I’ll have a finished project by the deadline as my timeline included finishing the drawing for printing tomorrow. It’s 9:30 on a TGIAF and after 4 cups of coffee I’m falling asleep so I probably won’t even open the drawing. I’ll still plug along and post as I go. The fun is in playing along and keeping busy in the workshop.