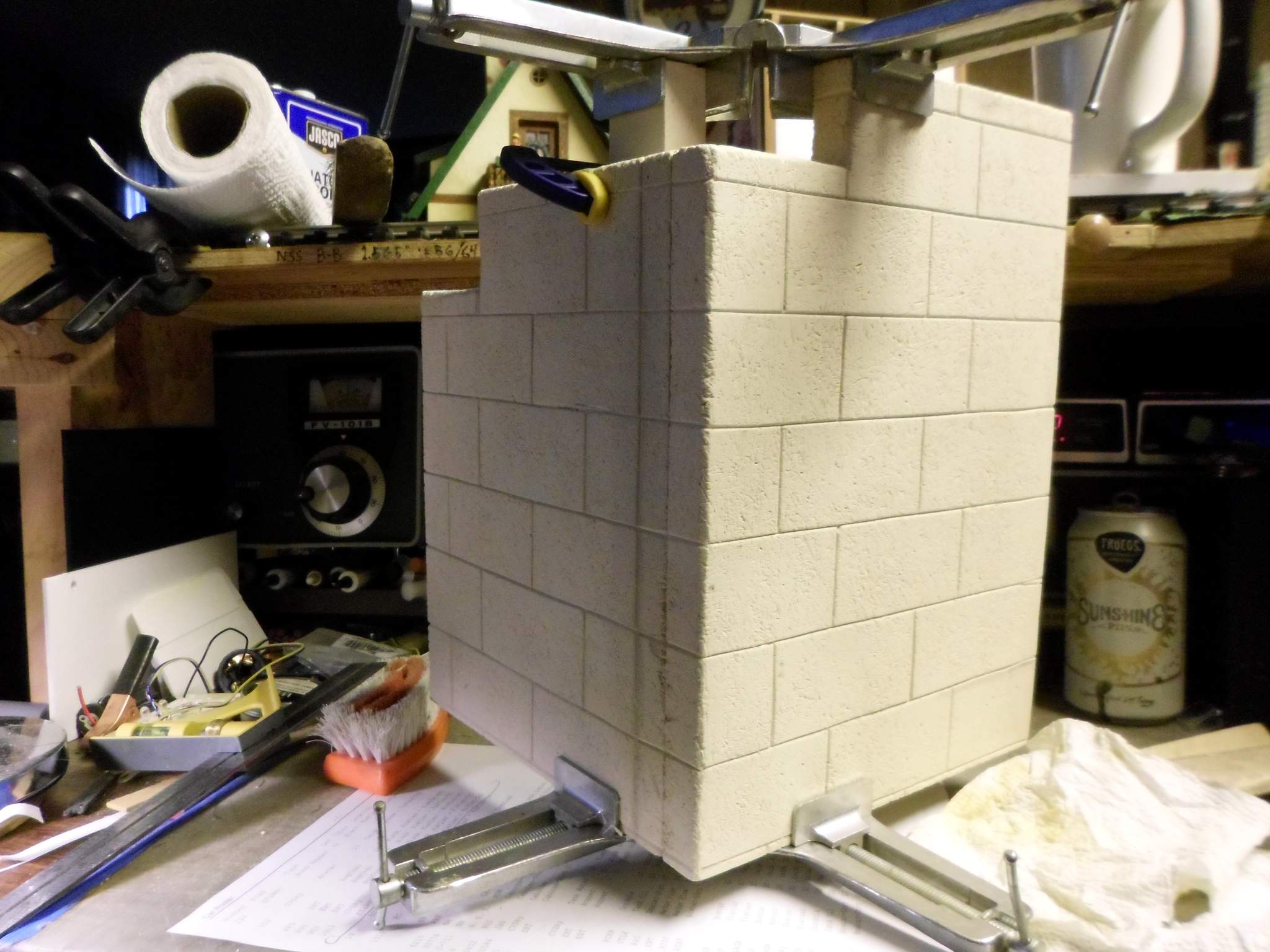

Got busy today getting the retaining wall blocks carved, detailed and ready for paint. I thought there might be some interest in the process, so I took a bunch of progress pictures. I am using HDU signboard foam because I can get scraps for free, but pink or blue foam from Home Depot or Lowes would also work. First, the block is laid out on a sheet of foam. A fat pencil line will help in the next step…

I got specs off the internet for block size which is 30" tall by 30" deep and 60" wide. I liked the big size as I didn’t need to carve as many lines. Next, I use an razor knife to slice each side of the pencil line at an angle…

I cut the lines free-hand. I thought about using my metal ruler, but that made it harder to get a good angle. Once everything was carved I used a ceramics tool to deepen the cracks just a bit. The HDU does not compress easily, thus the cut was required. Once all the lines have been carved, the surface is textured using an old wire brush. The nastier the better - this one has been in my garage for maybe 20 years…

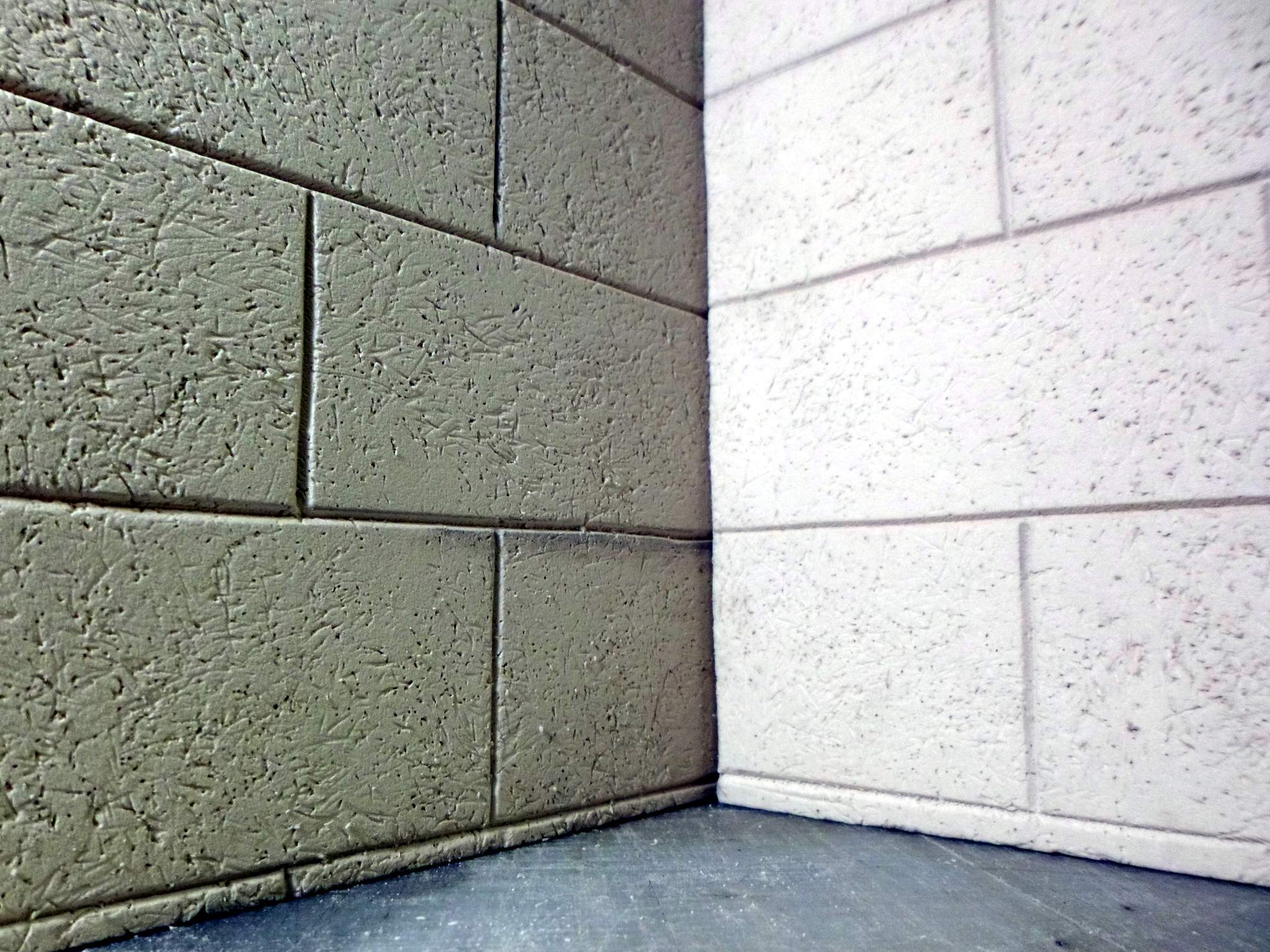

Bang, push, scratch randomly all over the surface to simulate an imperfect concrete surface. A close-up of the result before stain…

I did my best to get the blocks to align while changing directions…

On the outside corner the 30" depth of a block spans the joint between two 3/4" foam pieces…

I may try and fill this gap after the pieces are glued; or I might just ignore it…

Presently I am waiting for glue experiments to dry. I want the three sections to be joined together before I stain so that the color will be uniform across the joints. Gorrilla Glue is recommended as it us Urethane based, but I don’t have any. I am trying E2000, but I don’t like the 24 hour plus cure time. I have also tried a 5 minute 2-part epoxy which fully cures in 1 hour. I will know how that works in about 30 minutes. Hopefully it will be good and I can move on to stain this evening.