Don Watson said:

One of the reasons I like the longer, roll out wood boxes is that they allow you to avoid having to plug and unplug the engine/tender connectors which I found to create issues with connection durability.

Doc

Absolutely agree. But then you are dealing with a USAT Hudson, or a similar sized Accucraft or Aster locomotive, they can weigh 25 - 35 lbs. I always worried about dropping them if my arm fell off. So most of my carriers are 2 pieces and I get to reconnect everything when they are on the track.

I have made carriers from all sorts of materials, but I don’t bother with cosmetics. These were made from odd bits of wood I had lying around. The RH one with the white uprights is actually held together with 12" threaded rod inside thin plastic plumbing tube. Handles are closet rods cut to shape and underslung to provide strength. On the LH side the end block has a coupler mounted on it which the tender clicks in to. The ramps on the other end are held up with cords. There are fold-down wooden sides with foam on them between the uprights - you can just see the fishing line holding the cotter pins (so they don’t get lost when removed from the holes in the side panels.)

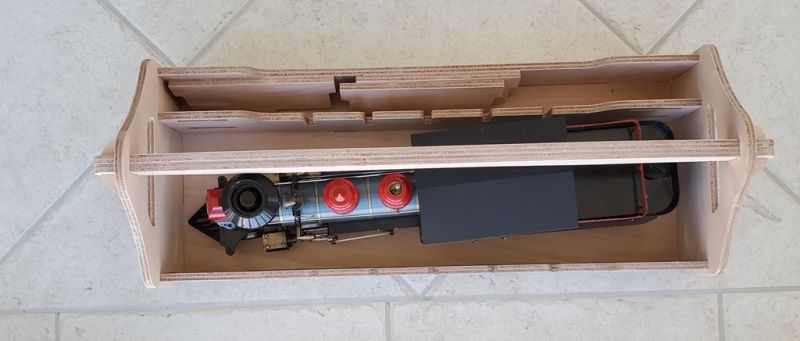

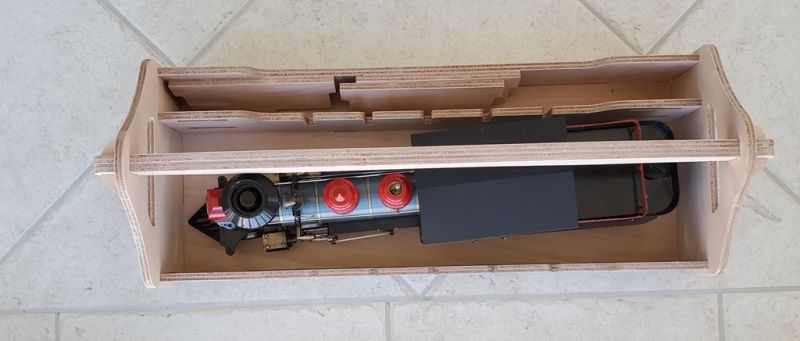

I do have one other type to show you. This is a toolbox made locally be a company that makes plywood ‘kits’ for kayaks, skiffs, etc. It is held together by pins of plywood (e.g. end of the handles) and the ends fall off if you remove them. At the moment it works for my Mason, but it is too low (the handle hits the stack) and too wide - we don’t need that extra tool caddy strip. I’m working on the company to get them to produce a simpler, taller version but they are swamped with pandemic business.