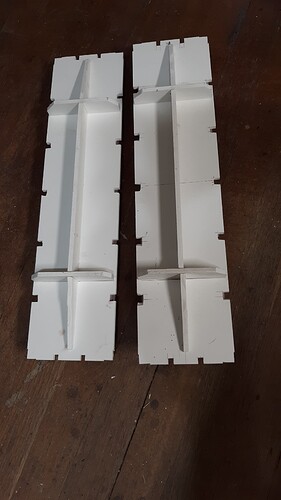

I started out by cutting some 1/4" PVC to size and made generous clearance cuts around the stakes. this platform sits down inside the car.

next i glued blocks of foam to the topside with spray glue, and let sit and cure overnight

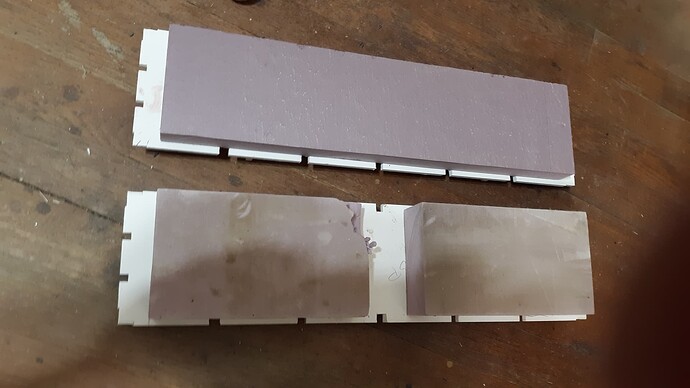

checking fit

I them sculpted the foam to the desired shape, one as a coal load, and the second as ashes and cinders,then painted the topside appropriate color, and after another overnight applied coal and cinder material to each with white glue. then when dry today i cleaned up and checked fit on the cars.

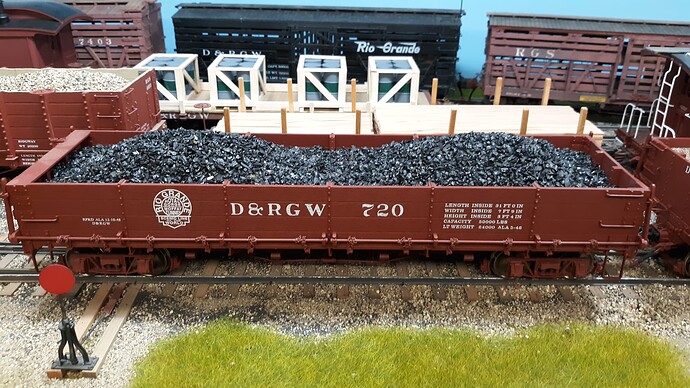

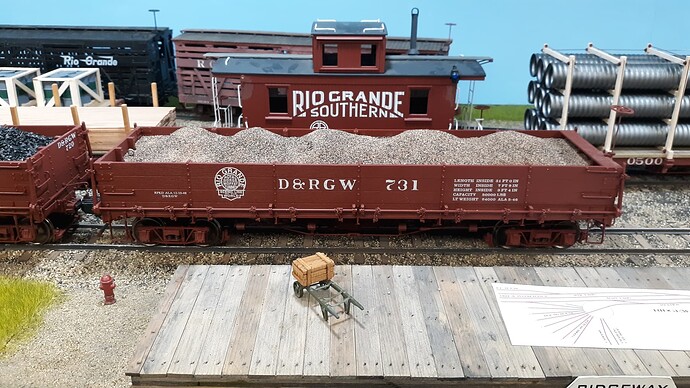

Here we see the finished product.

I have installed an screw eye in each end of these loads to facilitate removal, and am going to upgrade my previous high side gondola loads with the same. you have to look hard to find them.

AL P.