Andrew,

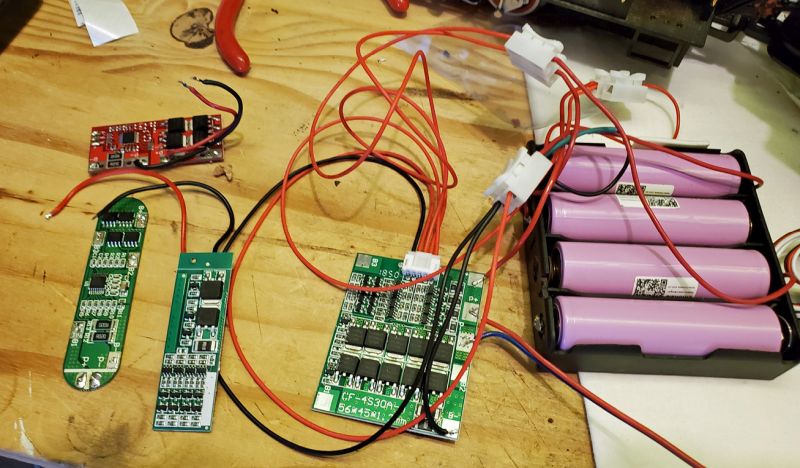

When I saw your post at first, I was skeptical of the 10 and 15A quoted discharge rates of your batteries. I haven’t purchased or played with any new Li-Ion batteries for several years, last time I went there I tested what were supposed to be high discharge 18650 cells, alas they didn’t perform as quoted and had a short life. These were not NAME brand cells. Anyway, I searched and I assume your quoting the discharge rate of Samsung’s 30Q and 35E 18650 cells? My experience with Samsung for the most part has been good, that said I just purchased four each of the 30Q and 35E cells for evaluation. After I run the cells through my test regimens I’ll report back if they can really produce the claimed current while holding rated voltage. As I noted previously discharge tests of 18650 cells typically garnered C2 or capacity x 2. The 30Q is claiming 10A/C3.3 and the 35E is 15A/C4.3.

Many moons ago I used to test and evaluate batteries for giant scale RC aircraft flight systems and later small electric stuff. Started with 800mAh Lithium Metal 18650 cells and progressed through many iterations of NiCd, NiMh and Lithium-Ion 18650’s and small Li-Poly batteries for 15oz. all up weight small electric competition aircraft. While NiCd was the most robust they were also heavy and ultimately, we were after the weight savings afforded with new Lithium technology.

I use a DC programable electronic load to simulate real world variable and sustained loads. Not everyone has the need for such a device, but I have found many uses for same over the years. When the kids and I got started with RC cars we observed others utilizing a bank of 10-30VDC 1157 automotive turn/brake incandescent bulbs to discharge or cycle their batteries. Each 1157 bulbs draw approximately 2.1 Amps @ 12VDC. Incandescent automotive bulbs are readily available and inexpensive so one could build their own array of same to load test batteries without breaking the bank.

Fuses:

Fuses are time constant. Maters not if it’s a 50-watt or a 2500-watt load. What blows a fuse is the amount of current it sustains over a specified amount of time. Fast blow and slow blow fuses maintain a constant amperage for different time intervals.

I like to run fuses that are 20% over size for the inductive load’s motors produce. In most circumstances, inductive loads require a slow-blow fuse due to voltage inrush and the momentary high starting current realized of same. Fast acting fuses are preferred IMO, yet they may not be able to carry the starting current of our trains. Its important to use fuses that are designed to work with the voltage in play. That said if you decide a 2 Amp fuse will suffice for your current handling needs and it survives the start-up current needs go there! Worst case is you realize a fuse with a higher rating is needed.

Polyswitches or PPTC devices are popular with model trains, and are well suited IMO. These devices automatically RESET when the temperature drops and or load is removed after an event.

To choose a fuses current handling capacity for a specific model train engine, the sum of all loads is used to calculate the size therein. Of course, we need to know the current draw and voltage in play of said engine. This number is unknown without benefit of actually measuring same. Many DVM’s (digital volt meter) offer the ability to measure voltage and current up to 10 amps I believe.

I think it should be noted that assuming the fuse rating and application of same will work as desired is foolish. I test and validate all to observe the fuse blows or opens the circuit as required! I wouldn’t be surprised if you had to employ a fuse of a different value than anticipated to observe the fuse unloads as desired. Additionally, if a standard or fast blow fuse will carry the current needs at start-up I’d always go there to protect he onboard electronics and battery!!!

I would NOT size the fuse to match the batteries capability in our model train applications. Protecting the battery and electronics is a prerequisite IMO, verses realizing the batteries potential.

In any case a little time on the bench with the right gadgets will allow you to discern the current handling needs for your toy train engines fuse protection and empirically reach a decision for the need of same.

Michael