insulate all those loose boards

Insulate? What for? (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

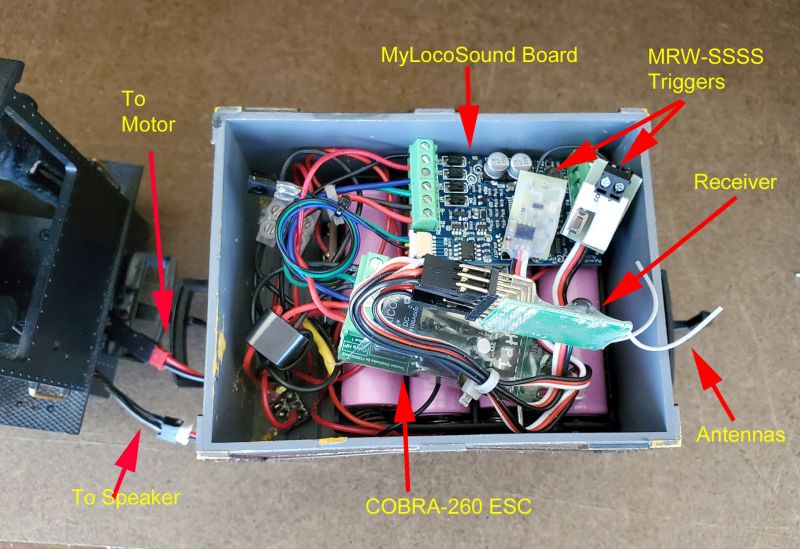

Actually, all of them except the sound board are encapsulated in plastic as if they have been dipped. You can see the slight sheen in the ESC and the RX. The sound board is sitting on a metal rod, so there’s some double-sided foam tape underneath holding it in position and insulating it. With the top (aggregate load) on, the boards are much more carefully arranged, with the SSSS tucked in the side of the sound board.

I was looking around for something to put in the top of the sandbox, as I am missing the curved lid. I found a couple of knobs off a track light bracket which are a perfect tight fit, and have a mesh-type texture inside the lip. I like it!

And a little video which shows off the sound system and all those whirring valve rods!

.jpg)