Devon,

Bite the bullit :). CNC router is THE way to go. It will definitely do your engraving. I used .015 diameter engraving cutters in a Haas V4 vertical mill to engrave lettering and logos into 45RC die steel (when I was in the die sinking trade-another life). Much more versatile machine than the laser. (IMHO)

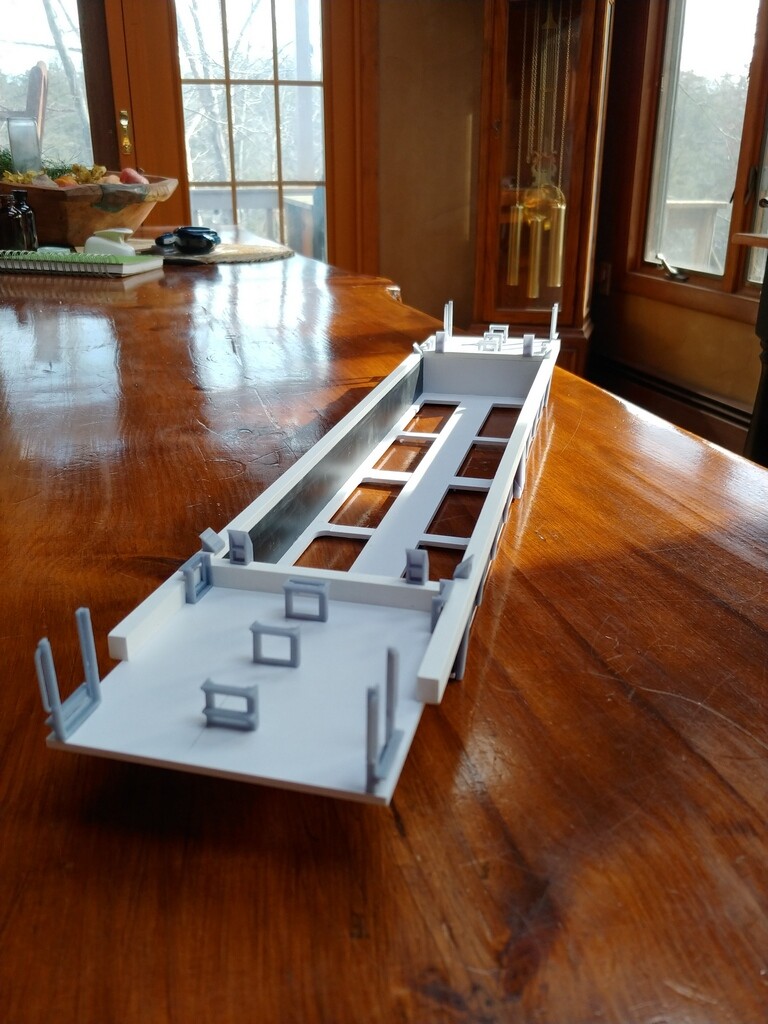

I don’t agree. Right now they are at the perfect height. I kept the lower “boxes” and they ride just above the rails. Any lower and I would have to remove them entirely.

Besides, I run them behind the FA/FB and before the modification they matched the heights perfectly. Now they sit a bit lower than the FA/FB, which is still fine.

And, I do have the Kadees in as close as they will go using shortened truck mounts.

Also, I gave them the ability to rock on their bolsters and this took care of the inherent derailment problems.

Revised:

Yeah Gary I think after having this discussion the CNC router is the way to go when I factor in not only the modeling aspect but use in my wood working and other hobbies and with the ability to add a laser to it really would be much more versatile than buying a laser and not being able to do the other stuff.

The one Dan steered me too is within the doable realm of not getting into to serious trouble with the wife.

Acrylic and Plexiglas are equivalent…

No.

I made this mistake once buying plexiglas thinking it was acrylic. The material is so much harder to cut and the Epilog couldn’t even get all the way through a 1/4" piece making a real mess along the edge that never did penetrate all the way through.

If one wants to invest in a CNC machine, I bought ShopTask TriPower years ago, but it seems that running the machine causes more problems than it fixes. These were made in 2006-2007 and run manual, power feed, or CNC if fully optioned, as mine is. Don’t forget to get a good DRO with/for it.

Not mine in the video, but similar. Mine looks to be in much better shape.

In machining, heavier is better for stability. These weigh in at 1,400 pounds.

Like the trains, even these are “toys” subject to high maintenance if you expect proper operation.

https://www.chicagolathe.com/content/12-history-of-3-in-1-machine

There are two kinds of acrylic sheet (cell cast or extruded), both of which can be lasered. Plexiglass / Plexiglas is the more expensive of them (cell cast acrylic sheet) . There may be slight differences, but not much from what I’ve read.

You may be confusing it with Lexan / polycarbonate, which does not do well with lasering (though it looks just like plex).

Must have been polycarbonate billed as plexiglass.

Todd,

“It’s all good” and honestly I don’t care either way, just being a typical ROOSTER . However you can go tighter and lower even swapping out with Ro trucks but this is a Laser Engraving /cutter question and I will stay on topic (if I can).

Thanks! I made it from 2 16’ sections of live edge that was part of a bar in a country western club that closed. It’s 9.5’ long x 45" wide by 3" thick. I used one of the cutoffs for our fireplace mantel. Craigslist find $100.

Dang , Dan!!! Robbery without using a gun to get that slab for $100, what and awesome find!!! I’m sure when you saw it you HAD to buy it even if you didn’t have a plan for it!!!

Thanks for this lead. He was generous enough to respond though he said the lasering was actually outsourced to a guy he knows and really was not “up” on it. But he referred me back to Cliff’s advice. But anyway I just wanted to say thank you and that he was kind and responded promptly

Well, I’m really surprised. I thought he cut it all himself. I guess I’m not nearly as knowledgeable as I thought.

He said he does the design/CAD work and then he got hooked up with a guy before he started the company that was able to do the lasering. Did it professionally and now is retired but he still outsources to him. It is kinda funny because he told me that the guy is secretive about his methods even to Alan.

Just purchased a Creality CR-Laser primarily for cutting basswood sheets for modeling. The laser is a diode type that works well for the cutting but wonder if it will help with scribing tongue and groove. Ever try doing that yourself, or, anybody out there try that?

My unit is only 5 watt as I did not plan on using it for art or etching.

Bruce, yes, I’ve lasered grooves into hard foam sheet for board, brick and stone joints. I haven’t done it on wood yet though. Here’s that project:

On the next set I want to make the grooves wider, which will require a second pass slightly offset from the first.

Keep us posted on how yours works out!

Cliff;

Strange we never ran into each other over the years. I used to know the owners of Piper’s Opera House and talk with them many times over the years. It cost a pretty penny to restore that place as it was real run down.

Cheers and thanks;

deneh

Yes, indeed!

Ah, Pipers… I finally got to see the interior a couple years ago, along with my wife and sister. I’d paid for a special tour, arranged by the barkeeper downstairs. When the tour got to the backstage area, the theater manager (our guide) started seriously freaking out over the ghosts back there. I didn’t sense anything, but was tempted to try singing Handel’s Hallelujah Chorus just to make sure…  The poor woman honored our tour commitment, but was a wreck by the time we got out!

The poor woman honored our tour commitment, but was a wreck by the time we got out!

Cliff,

It may not be the first time there for your sister? Wasn’t I there on the 2nd floor of your scale model?

May I just add that since being discovered, Cliff, Rooster’s modelling career has gone through the roof.

However…

Cliff, now that you posted the link I understand why.

However,  The article states ”much of what has been written about Julia C. Bulette[(’s) love of roosters] is pure fiction”.

The article states ”much of what has been written about Julia C. Bulette[(’s) love of roosters] is pure fiction”.

Julia, a woman of wit and eccentricity, loved her flock of clucking, feathered friends and insisted that no one could attend her establishment without paying homage to them.

Every evening, miners, drifters, and firemen lined up at her door, each carrying a squawking, flapping rooster. The scene outside was one of chaos—cocks crowing, hens pecking at the dust, and Julia laughing heartily as she welcomed each guest with a smile.

“Ah, that’s a fine-looking cock!” Julia would exclaim, pointing to a proud rooster perched on a miner’s shoulder, before placing his rooster with her hens.

- Apologies for the paultry poultry taxonomy

- I have already reported myself to the moderator for the use of foul fowl language!

- Try the veal