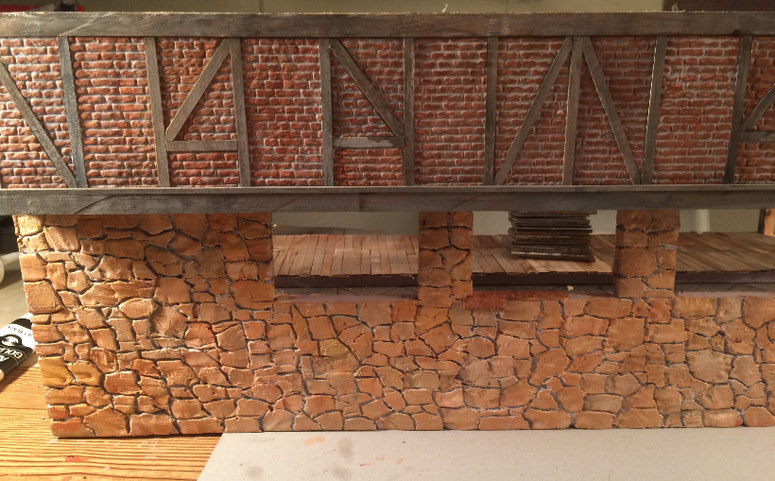

More progress. I think it’s coming together, although I have much to do, really a lot left to do. Oh boy is there ever.

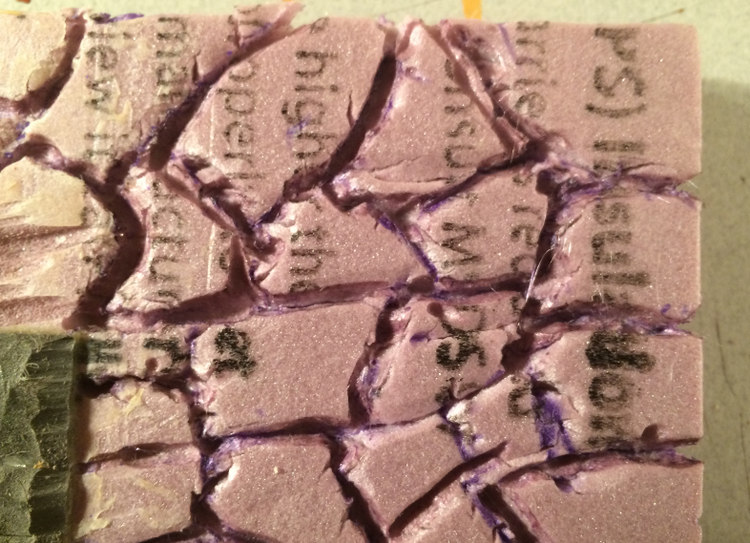

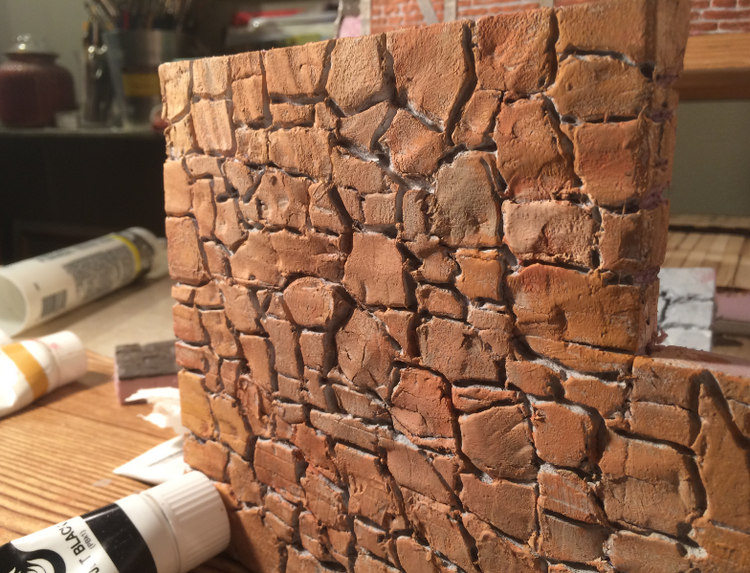

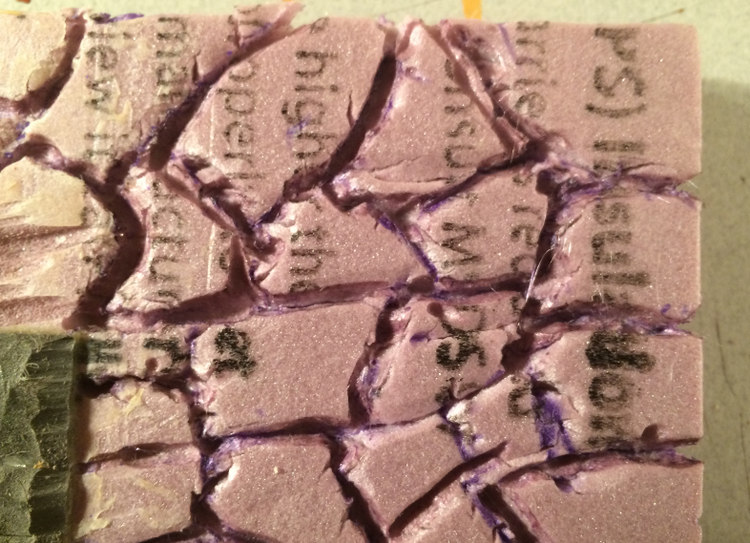

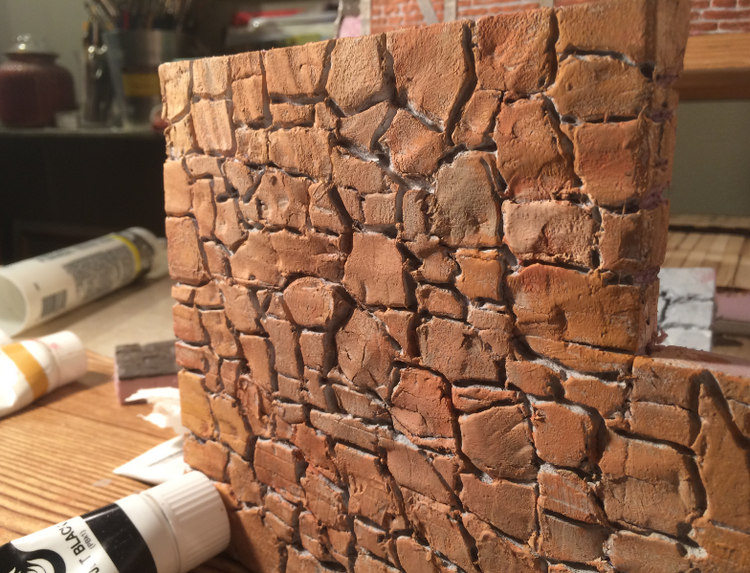

I tried something different with the rock work this time. I used the welding gun, which I will surely never in a million years use for welding anything, to carve out the grooves for the mortar. You got to use a light touch because this thing gets really hot; in fact, I unplug it and use it as it cools down. You can see where I’ve drawn out the lines with a pen first, sort of lightly scoring the surface…that way I don’t have to concentrate anything except following my drawing when I have that hot welder running on the surface. The third picture shows something different…I thought to fill the mortar and motor color in the grooves first, then color the rock, instead of the other way around, and, also, I covered the rock with the gray. It will show through in spots and give a cool undertone to all that warm rock color.

This is how it turned out after I roughed up the surface with the end of a paint brush, the front of some of Dave’s tiles!, and with my thumbnail…if it’s all flat it doesn’t look right to me, so this helps, and the insulation is pliant.

I’ve been tackling the stone work on the fireplace. I saw where Eric used latex caulk to cement the stone into place and it seeped through the cracks and he called it mortar (by the way, Eric, that build is really good), and it got me to thinking I could fill the cracks with caulk and then paint over that. I didn’t want the seams between stones to show, and I wanted the mortar to fill between irregular rock. So this is what I did:

Also, here’s my solution to the cornerstone issue. I took my dremel wheel grinder and ground down the edge until it isn’t visible any more, then painted it. I think this came out well…I’ll get better at it as I go along:

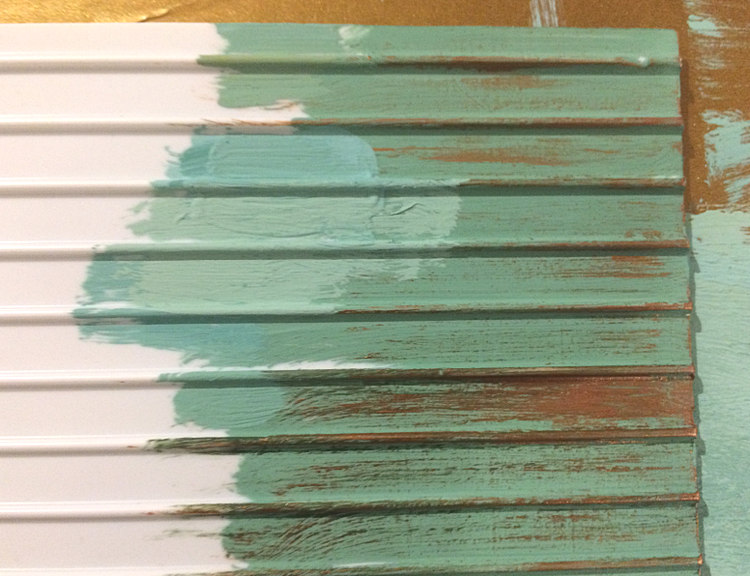

Then there’s the floor of the engine house. I laid individual wood strips and for me the best way to integrate them is to use ink. I use my drawing inks, India ink, which is black, and sepia ink. Looks like this right now:

Then I started working on the interior walls. Dave mentioned the doors to the Southern engine house are painted a light gray and I thought that would be perfect for the interior walls too, so I started laying strips of wood. THEN, it hit me, Rooster’s method of scoring and painting. So I got my pen out and scored the insulation and painted it light gray, and, there you go!!!, twenty minutes of work instead of three hours of tedious cutting and gluing. (I’ll have to remember to buy David whatever his favorite drink is. I’m sure somebody here might have a suggestion.) By the time I’m finished it looked plenty fine.

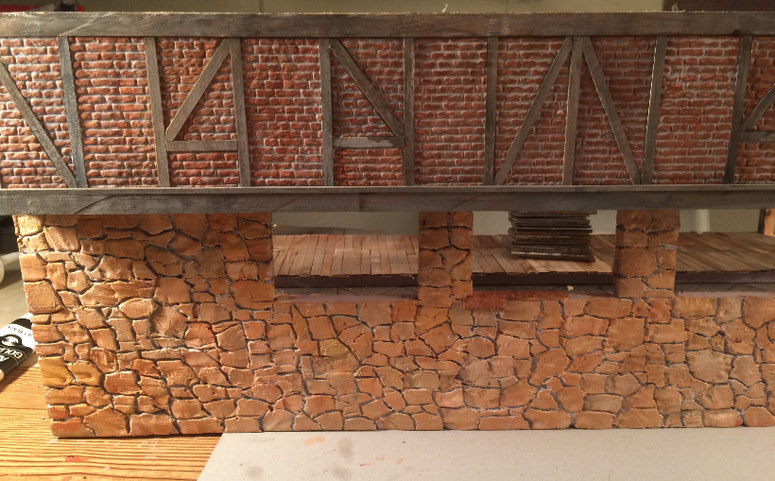

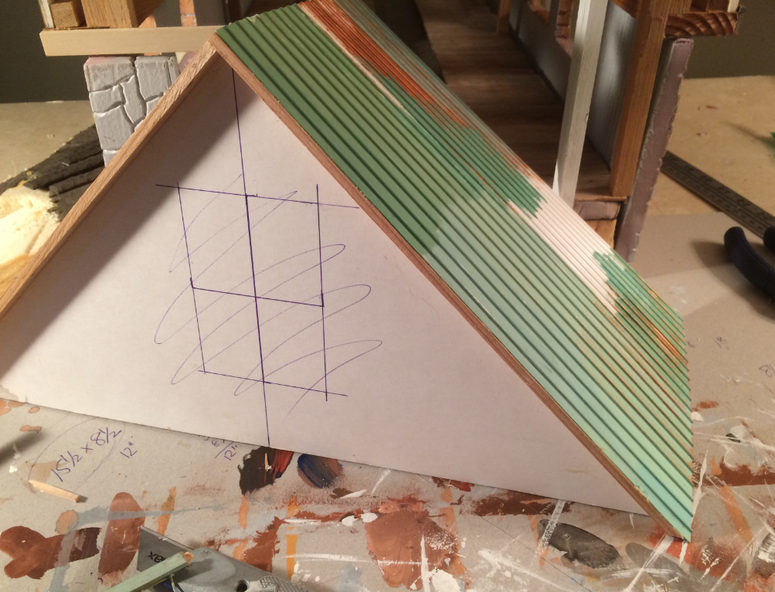

Finally, I thought I’d throw in a couple of pictures of how one of the side walls is coming together.

So that’s it for now. Later tonight I’ll get back to work on it. If you have any suggestions. especially time-saver suggestions, or if you see something that doesn’t look realistic, or believeable, please do me a big favor and speak right up. I tend to look at my own work through colored glasses, but I am not sensitive to criticism. Thanks.