Jim Rowson said:

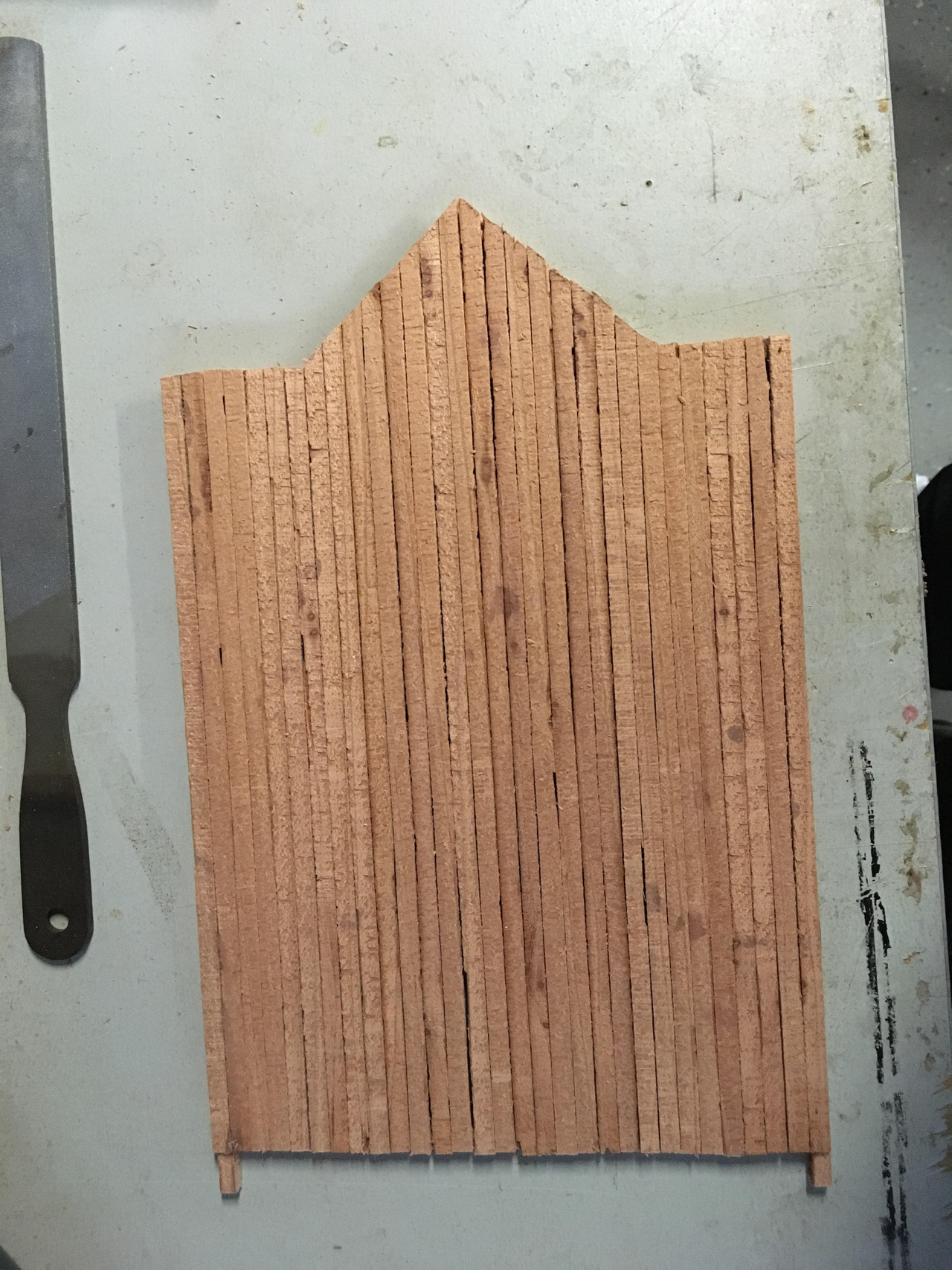

I actually used my band saw to cut it approximately 1/3 thick and then sanded it a bit more. Not totally uniform so I still have a bit more to do there but so far it isn’t too bad. Glad to hear this isn’t a completely stupid idea!

Stupid? its genius if you ask me. Now I tried doing it with my band saw both with a coarse tooth blade and also with a fines scrolling blade. Both times I tried it they shattered. Thats why I went to sanding. My materiel is old and may be to brittle, it just went poorly for me.