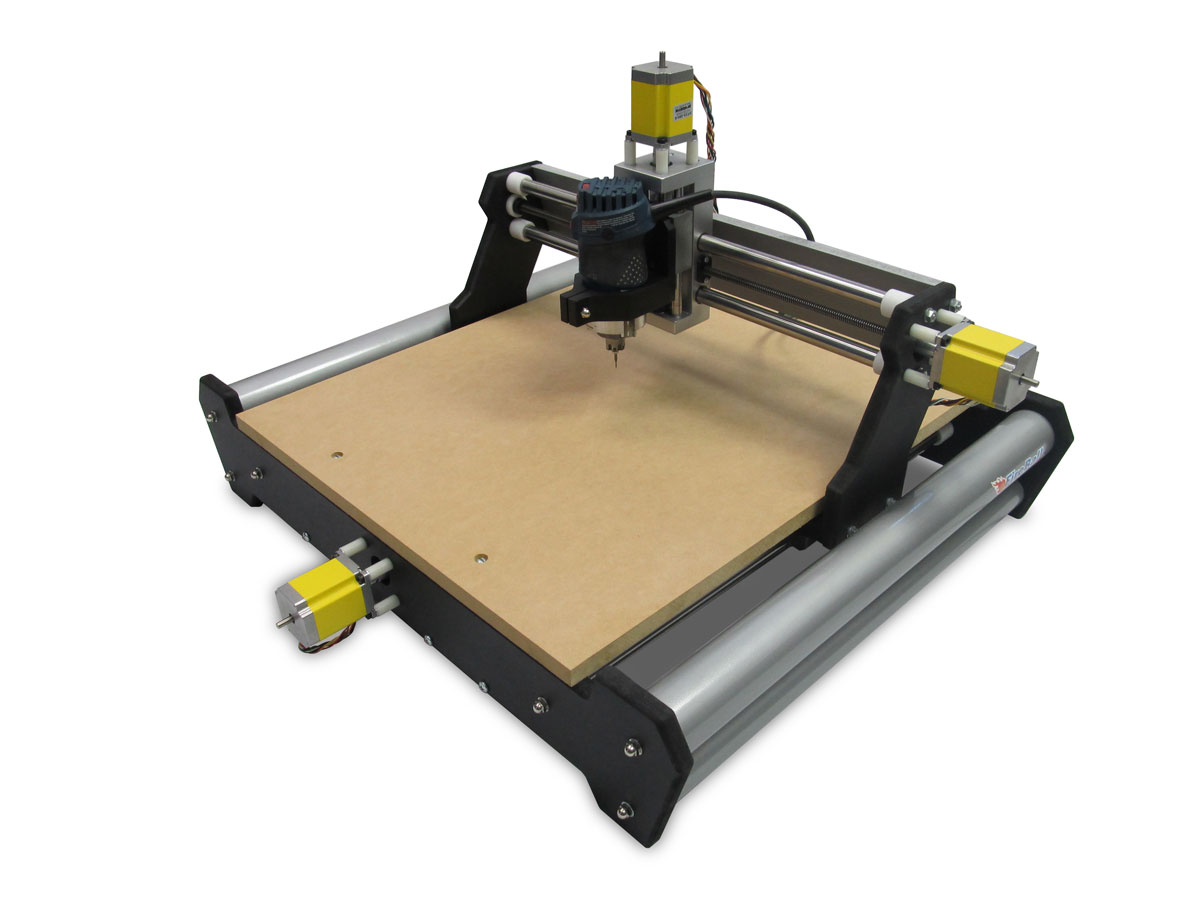

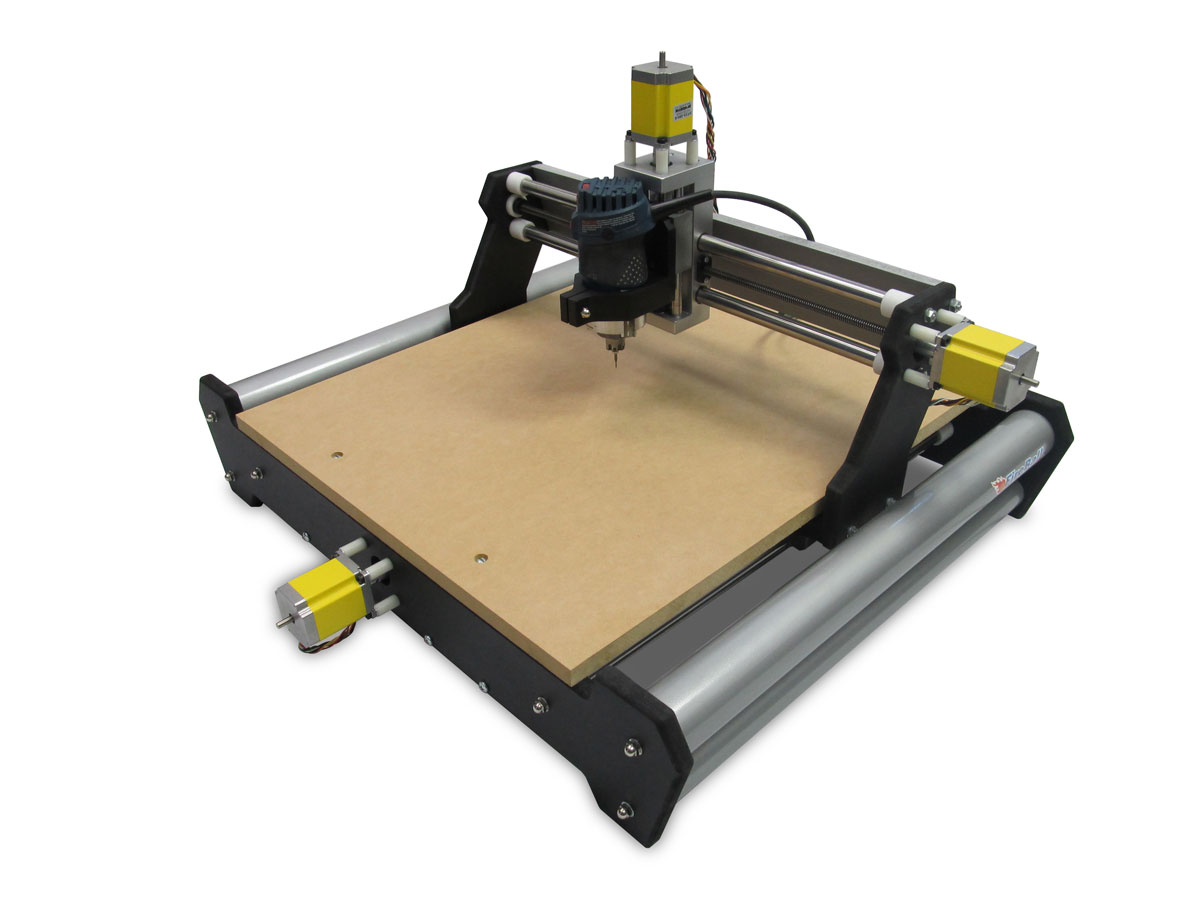

Well, I’ve been saving for this for a year now, but it finally came today! Yay!

Of course, I still have to put it together but that should be fun too!

Well, I’ve been saving for this for a year now, but it finally came today! Yay!

Of course, I still have to put it together but that should be fun too!

Very Cool Martin. Do you have some specs on it? Brand, envelope size, ect. ? My buddy just assembled his 3D printer and had some challenges along the way. I asked him if he wished he had bought the assembled version, and he was still very happy that he got the unassembled version. He felt he knew all the more about it for having overcome his challenges. Have fun and report back.

Edit: Oops, when my reply popped up I saw the brand link in the lower left! Thanks!

Gee, a CNC router. That could really come in handy. I am not sure I do enough scratch-building to justify having one though.

Well, I’m a nerd, this is just way cool even if I only cut circles out with it

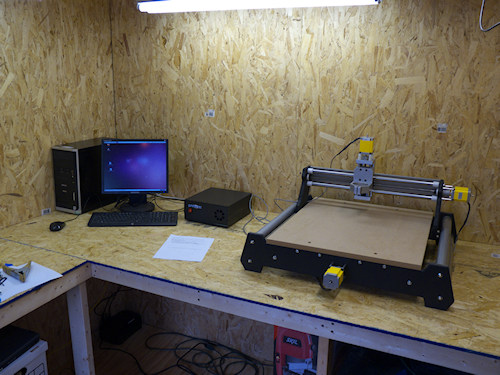

Finally got it all hooked up and working. Drawing squares and circles with a sharpie to test it out before I try out the router…

That looks pretty cool. Other than squares and circles, what’s your next project?

Very cool. I’m familiar with the large format commercial units (handle a 4’ x 8’ sheet) but had never seen a compact unit like this. The large units have a vacuum table to hold the workpiece. How do you secure the workpiece on the small units?

Martin, that is a neat corner, but where is the dust collection system. I am sure your computer will not like the amount of extremely fine dust that rig will emit. There is another thread on the forum about a router like yours, but larger. I think it was Chuck Inlow.

My primary focus with this is to make buildings and structures for my 3D peoples to live and work in. I have plans for a basic vacuum system for chip and dust extraction but I want to lean toward milling styrene and plastic sheet so I’m not sure on that yet? It’s a learning experience to say the least! But way fun.

Milling plastic. I have no first hand experience with that, but I wonder how to mill plastic without it melting.

You can machine plastics with a router using standard wood working tools, you many have to adjust speeds. You will generate small flakes of plastic that will stick to EVERYTHING!!! Experience here is using a carbide tooth blade cutting plastic piping. It’s like snow…

Have fun, but be ware…

I have a super PID speed controller on order for my router. Should be able to crank in really accurate low speeds with it. From the guys on the router forum, using one of these is the best way to do plastic.

http://www.vhipe.com/product-private/SuperPID.htm

Thanks for the heads up though, I had a feeling stuff would be flying all over- hopefully my vacuum system will pick up most of it.

Martin what type of router did your machine come with. I have a Super PID on my machine that controls my Porter Cable 1-3/4 HP router. It allows me to adjust the RPM of the router as low as 5000 rpm up to the max of 28,000 rpm. As far as cutting wood the smaller the dia of the bit the higher the rpm and the bigger the dia the lower the rpm. Plastic or styrene is a little different you need to slow the feed rate so you don’t melt the material onto the bit.

As suggested invest in a vacuum system before you do a lot of cutting. Dust is the enemy to your computer, your machine, and to your health. Have fun learning and playing.

What type of design software came with your machine. I use Vectric VCarve Pro. The latest upgrade comes with 3D models and the capability to produce 3D items. I’m looking forward to getting this upgrade and making some new items.

Chuck

I got a Dewalt DWP611. It didn’t really come with the machine (just the mount), I ended up cashing in some credit card miles to get it as I was scrimping quite a bit to afford everything. But it gets good reviews on the Probotix mailing list and seems to be quite solid.

For CAM software I wanted MeshCam but Probotix no longer offers it as a bundle with the machine. Too bad because they had it at a sizeable discount. But I’ll probably go ahead and buy it soon anyhow. I’m much more comfortable in the 3D world rather than vectors and dxf files so MeshCam seems to be the right choice for me. Plus it’s not too expensive (well $250 seems expensive!) For now I’m testing using my normal 3D toolchain that I use for figures plus a freebie- PyCam to do the tool path generation. PyCam is ok but it’s really really slow on anything at all complex.

I do have a vacuum system I’ll be putting on it, it’s just not in the pic as I haven’t even gotten the router mounted yet. I think it’s going to be a bit before I get to cutting, I’m still sort of tweaking everything and going up the learning curve (or is is down? ha). Plus I want to put the Super PID into a clean router and it won’t be here for a week or so.

Martin Sant said:

Well, I’ve been saving for this for a year now, but it finally came today!

Congrats on the purchase.

Very cool!