Just before midnight last evening I put the last screw in the tender shell of C.V.S.Ry. #8. What started out as a simple sound board swap turned into a major -re-wire / re-configuration job, but it is finally done. I learned and shared a lot along the way and the C-19 sounds great. The photos I took are just back from the processing lab, so I can share them with you now.

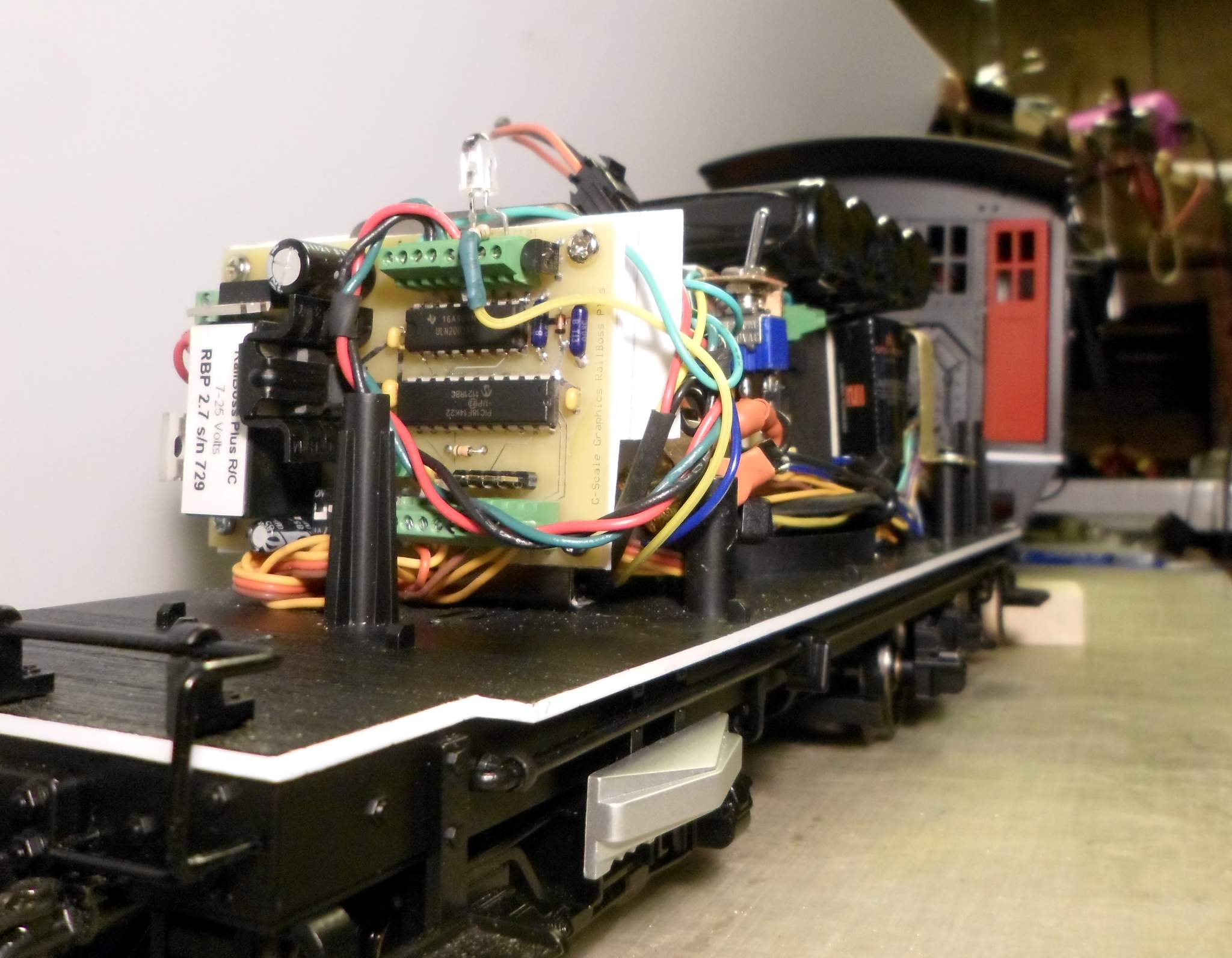

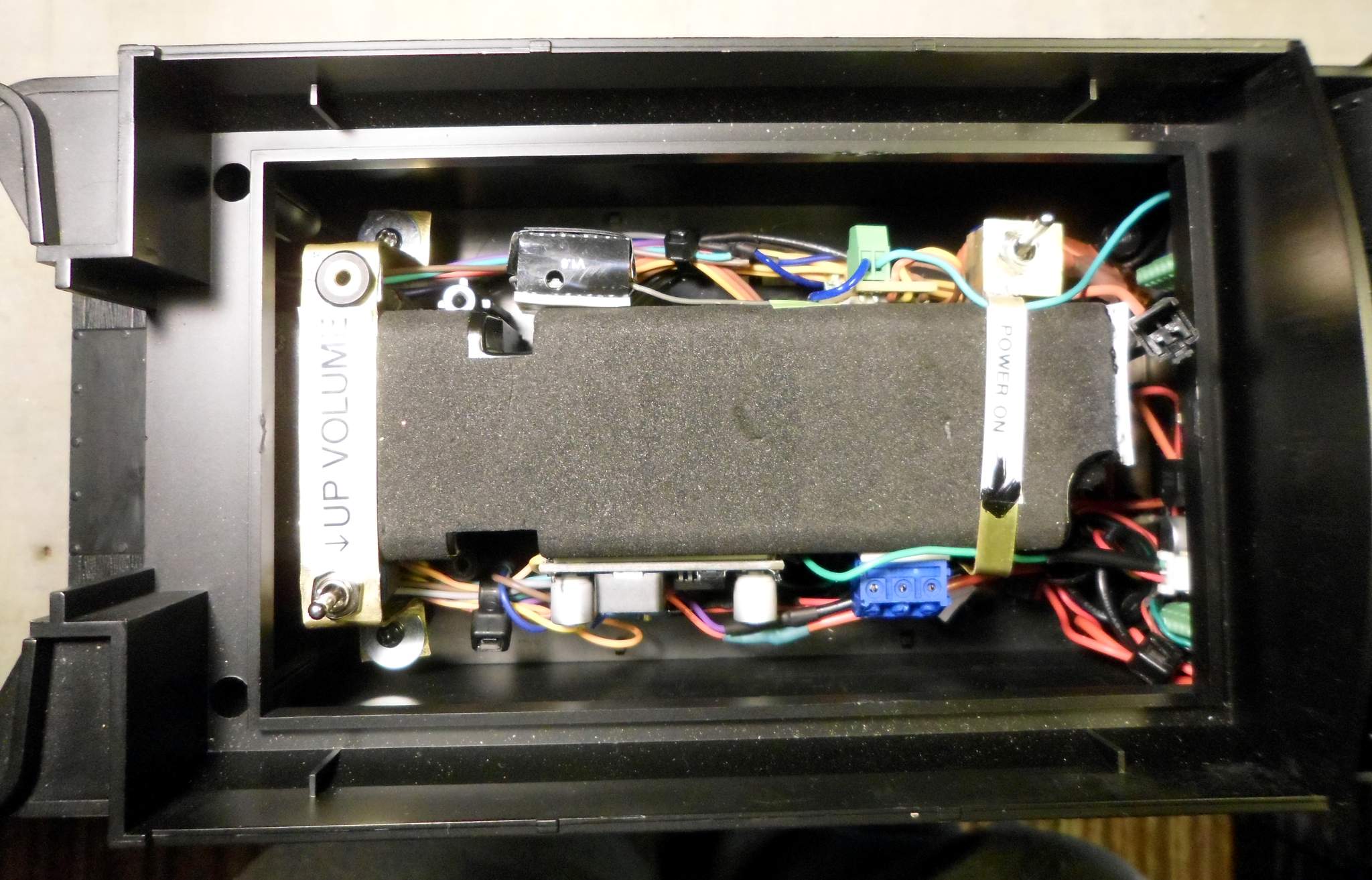

First up - View from the rear: The Railboss Plus board remains in it’s original position attached via a piece of styrene to the fan bracket (Thanks Doc!)…

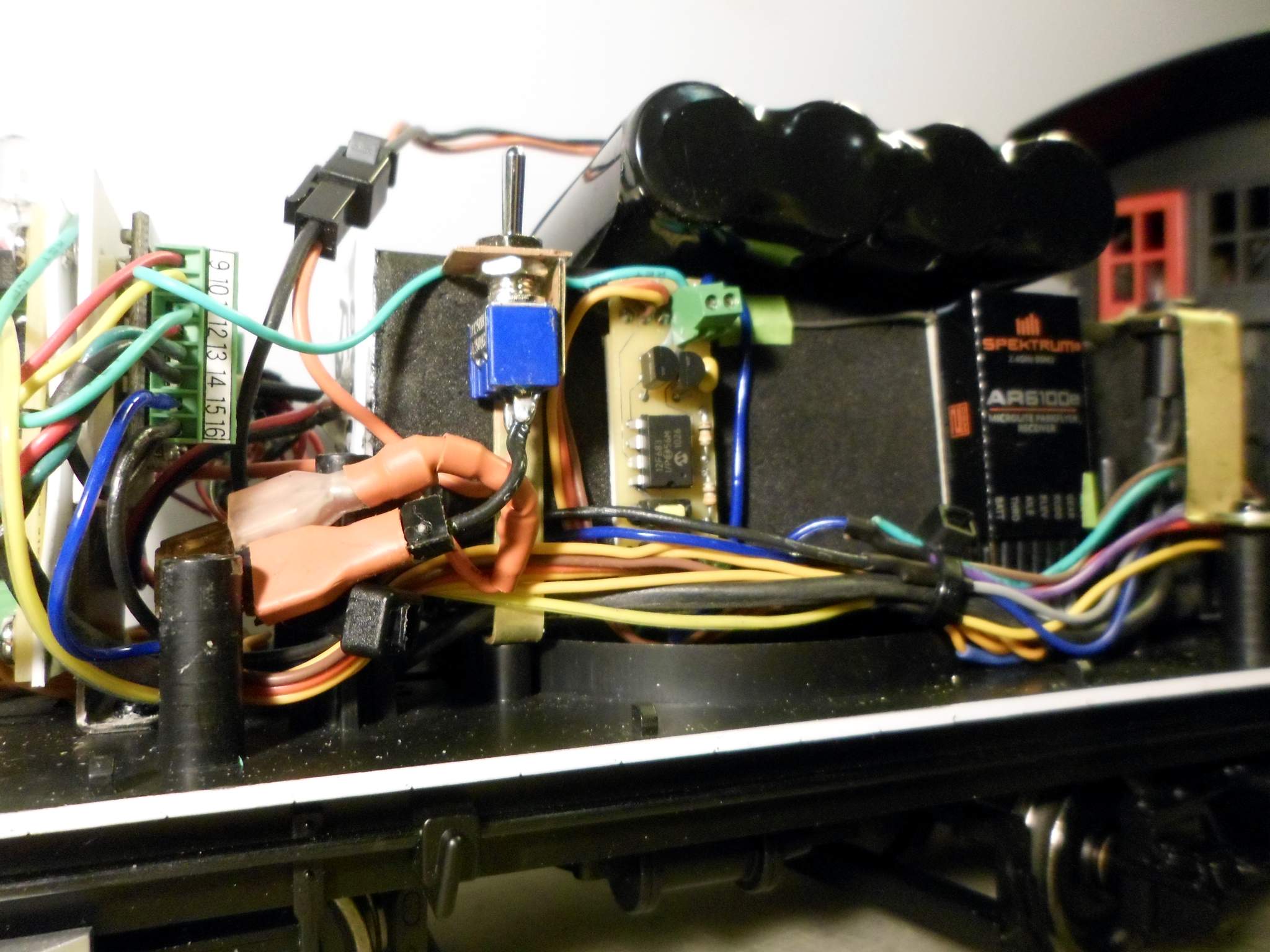

Next, from the Engineer’s side left to right: A phoenix 2K2 board stuck on the front side of the fan bracket. At the bottom a 5A fuse attached to the female side of disconnects, above that the battery connector. I soldered a switch mount to another brass strap bracket fabricated from flat stock that is used to hold down the rear of the speaker enclosure. This was the first production use of the resistance soldering set I got from Bruce (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)- To the right of the switch is a Railboss 2 Output Trigger Board. One output is a sound trigger for the Phoenix, the other turns the class lights on and off. At far right is a Spektrun 2.4Ghz receiver. A a 4 cell LiIon battery pack fits On top of the speaker …

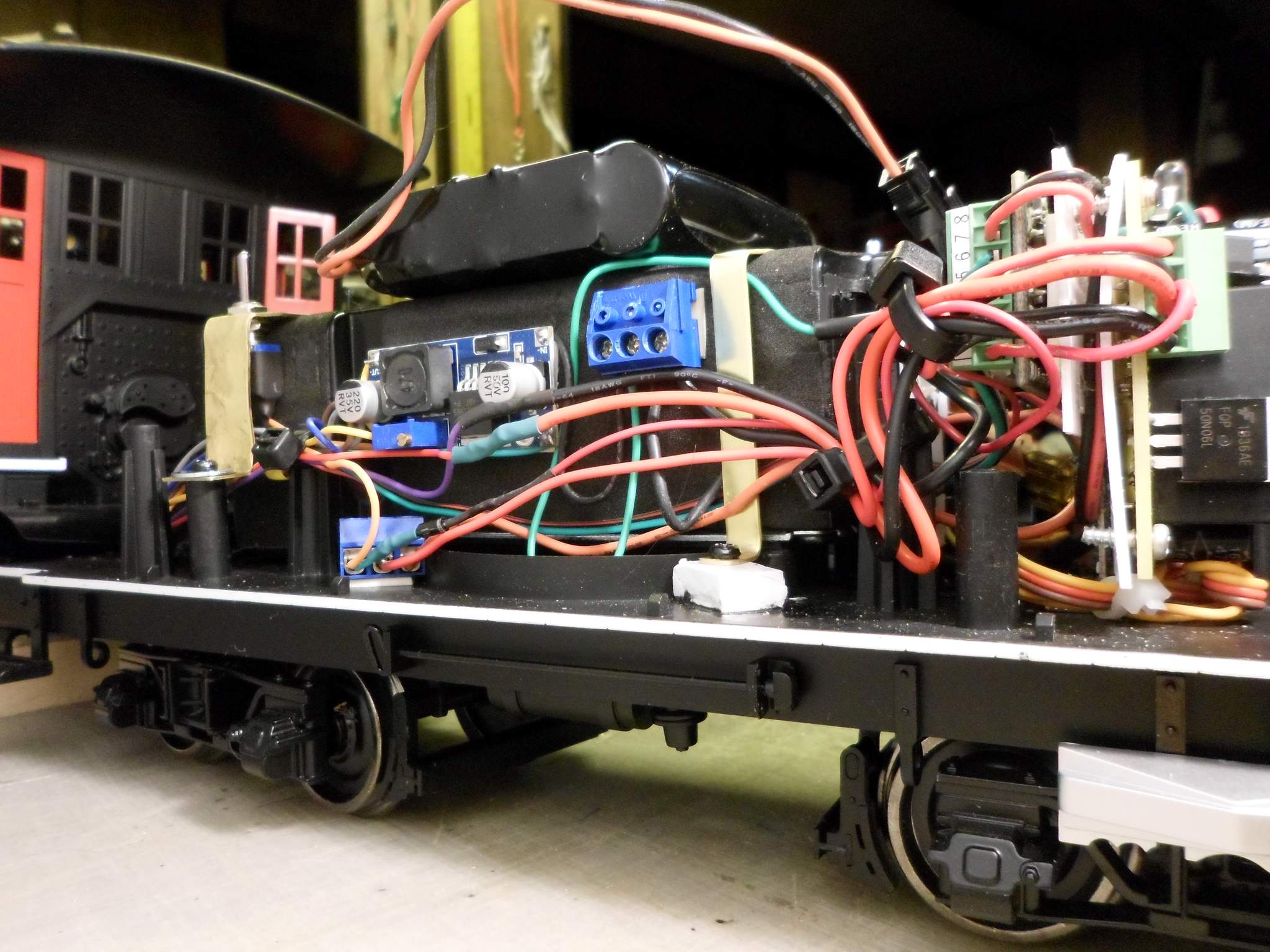

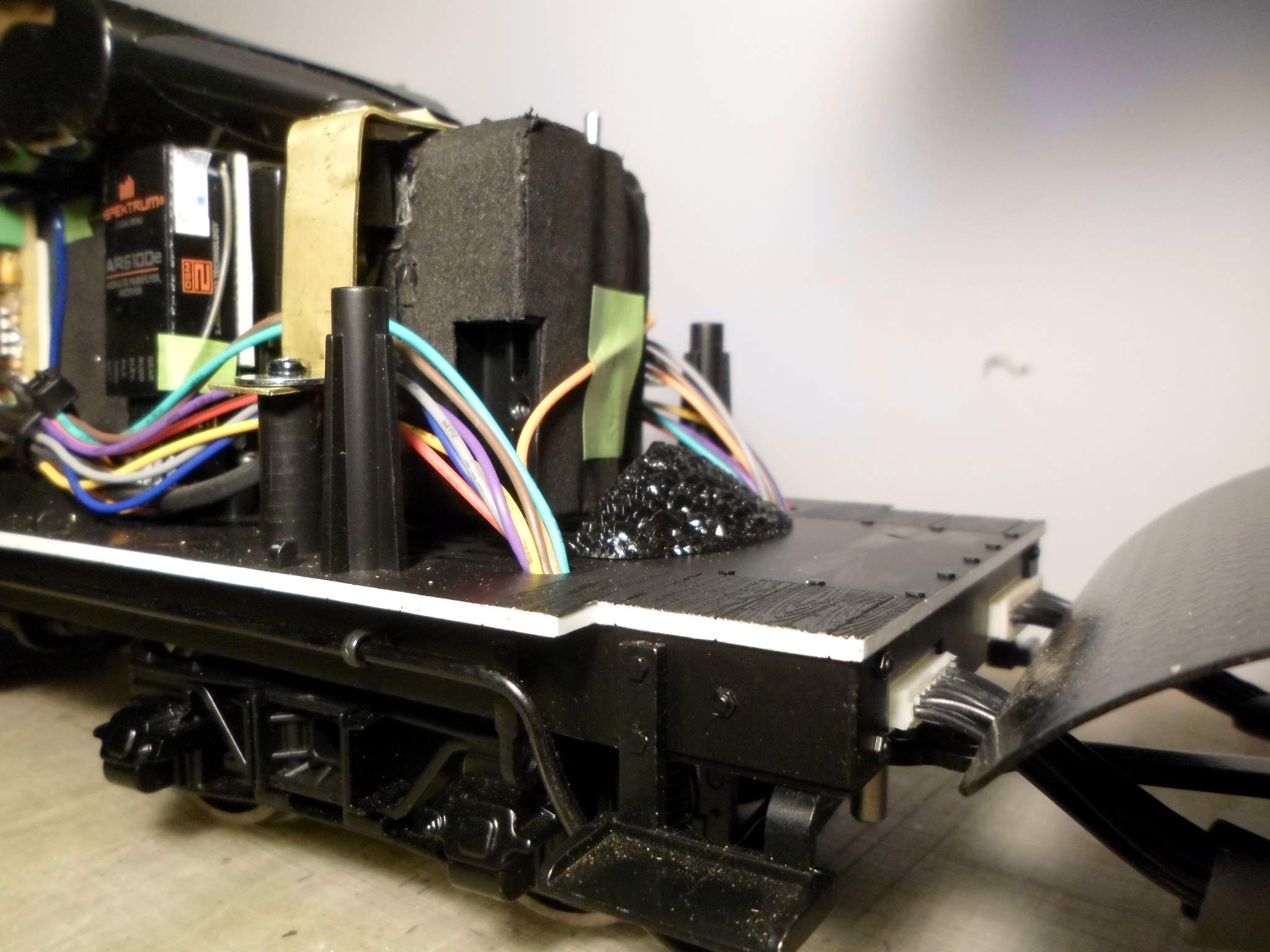

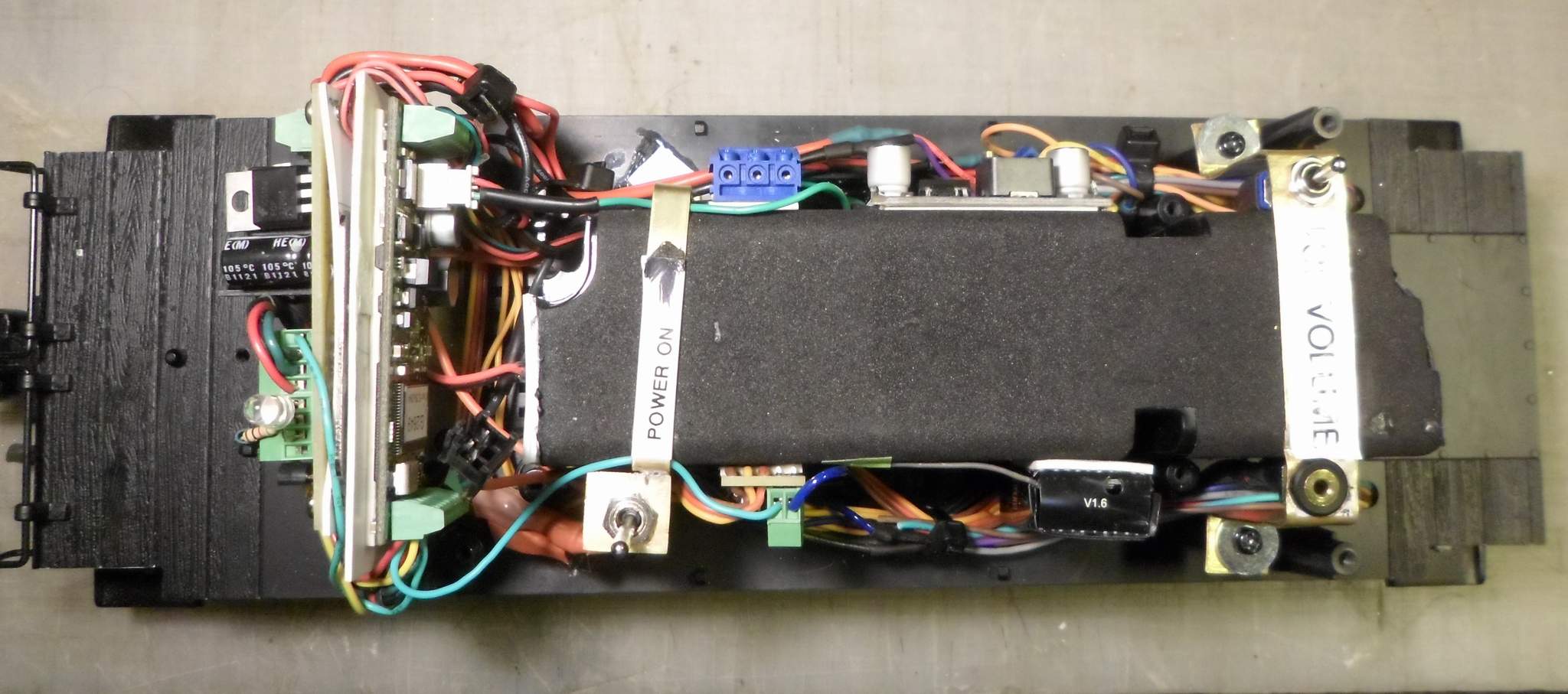

The top view - The 4 Cell Lion pack I picked up from Don Sweet at RCS New England fits nicely atop the speaker enclosure under the coal load. Doc Watson’s bracket idea at the front was re-purposed to hold down the speaker as well as carry the volume switch and programming jack for the 2K2. The new speaker hold down bracket at the rear carries the on-off switch…

On the fireman’s side from left to right: Front hold down with volume switch, a DC to DC converter that takes the 12V rear fan power and steps it down to 5V to power the chuff circuits and lights. I could have grabbed 5V from the Phoenix, but for $2 each in a 6-pack, the converter eliminates dependence on the 2K2. Below and to the right of that are terminal blocks for the battery output, and behind that mass of wires, the Phoenix 2K2 and the Railboss sandwiched on the fan bracket…

Moving back to the fireman’s side, now looking from the front, The component layout that I just happened upon worked out so that only one wire (5V to loco) needed to go to the other side. I ended up using all but 5 wires. Unused wires are insulated and still in the bundle in case I ever decide to power the smoke or do other things…

View from the top: Everything fits comfortably within the shell. No floating wires to fudge with when putting the shell on…

Another top view with the shell in place…

And finally, the battery in place - Free plug for MTO Battery. I’ve been running this pack since August and have only needed to charge it once! Guess I should run trains more…

So, the fat lady has sung and/or the fork is in the Rooster, because it’s DONE!!!