The last time it was nice enough to run trains, I tried to do some switching and found that both mainline switches at Indian Hill Junction had issues. The one leading to Bruce’s Mill and the engine house (#6 R) would derail everything on the diverging route and the one leading to Radder’s Mill (built by Ken) and the Walk Landing Transload (#6 L) had a broken throw bar. Friday was nice enough to pull them up for repairs.

Yesterday was rainy and a good day to get them fixed. I started with the #6 R. It had a noticeably bent point rail so I disassembled both point rails. One was good, the other was carefully returned to it’s intended shape. After reassembly testing with a truck didn’t go well. Closer inspection showed that one of the stock rails had a downward bend causing the truck to jump the point rail. A couple of well placed careful blows with a hammer got that straightened out. Once the switch passed the truck test, I flipped it over to fix some electrical continuity issues and add my patented throw bar reinforcement…

Just a small strip of brass with a couple of holes. This will hold up to the pressure of the Bachmann throw. The same fix was applied to the other #6 who’s only issues where the throw bar and continuity. Before closing up shop for the night I touched up the paint with some acrylic browns.

Today, there should have been enough time before the rain came back to get them both placed. I knew I had an issue with the left diverging track being too high for the switch to land flat on the concrete pad. Here is where the Project part comes in!

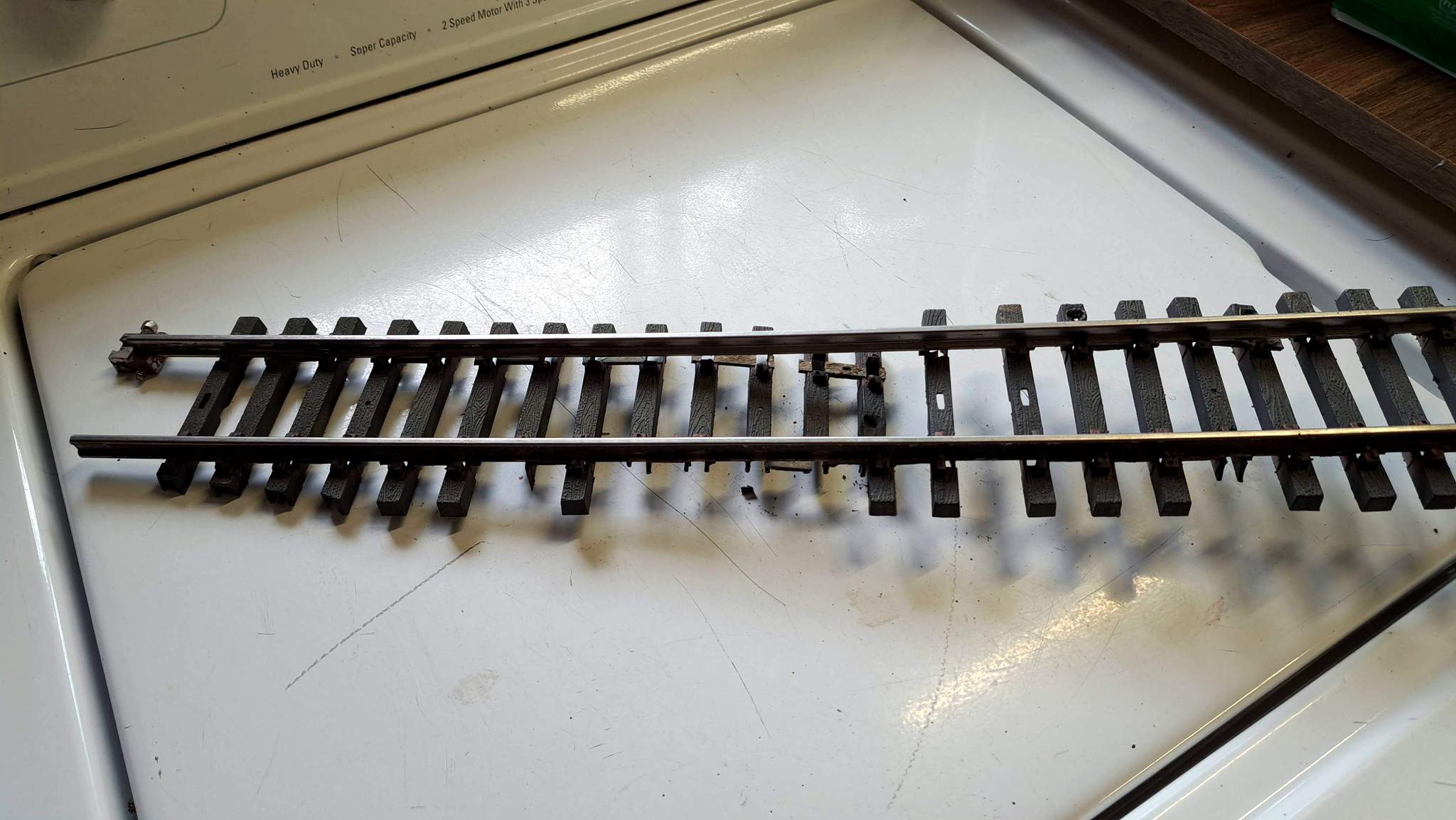

This is a spot where PVC spline roadbed lands on a shelf of the concrete switch pad. I thought I just needed to excavate enough to push the roadbed back down, but when I gave the track a couple of taps with a hammer, ties began to shatter. So, up comes the track section and back to the shop to replace ties. Before…

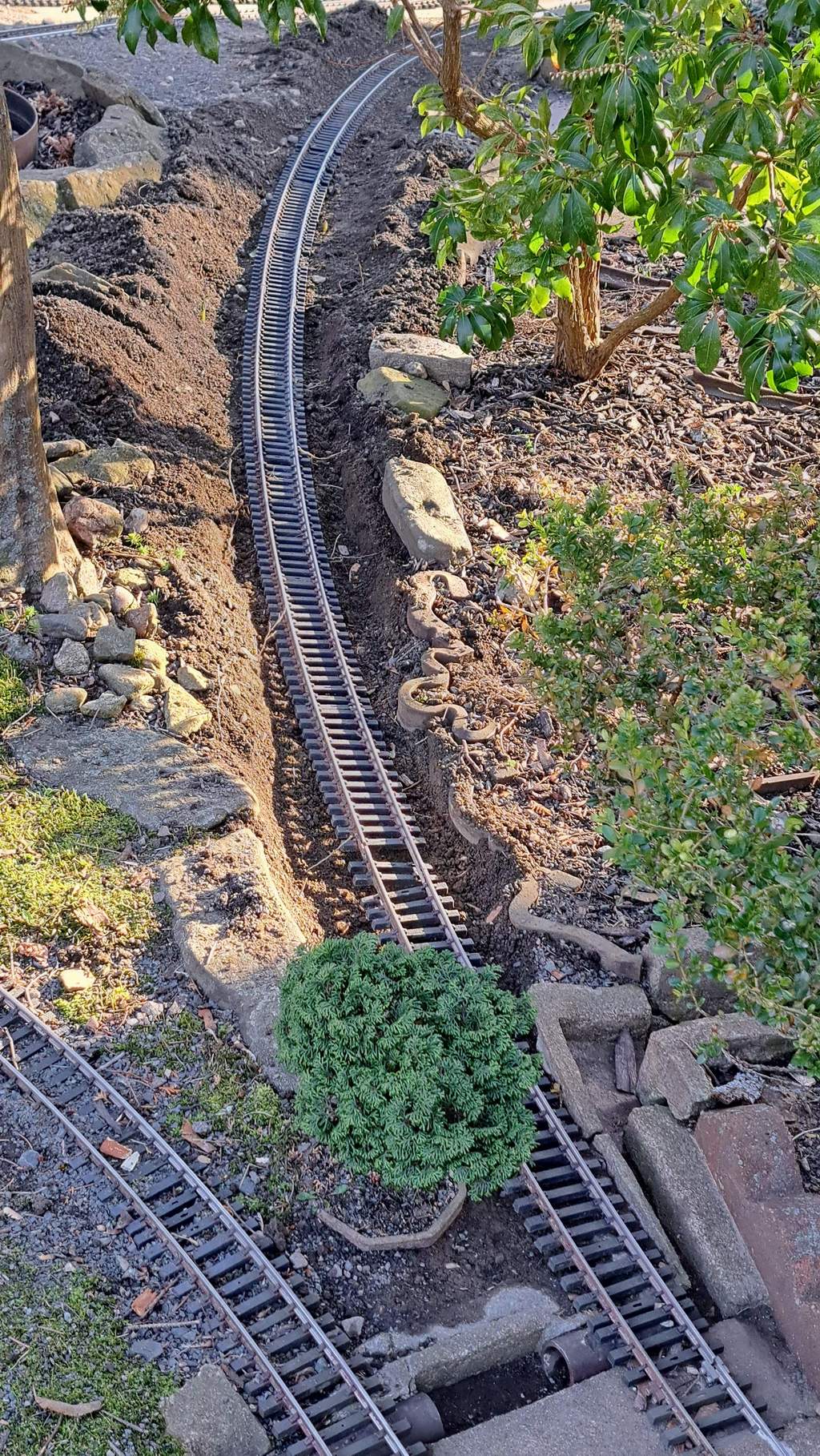

Sharp eyes will notice one broken tie end. I decided that wasn’t enough to replace a whole strip. Once the repaired track was painted, it was back out to the garden to fix the roadbed. More excavation and replacement of a gauge block that had rotted away and I finally got the PVC down where it belongs…

Most of my track is assembled with Aristo joiners with Split Jaws at both ends of every switch. I changed out all of the tiny cap screws for the truss head screws Aristo used underneath to attach ties. I find them much easier to install and remove.

I managed to get the repaired track section and the left switch in before the temperature plummeted and it started to sleet…

Aligning the right switch will be a little challenging. I’ll need to relax all the Split Jaws to allow stuff to move around, The goal will be a straight main line and as little gap as possible at all the diverging routes. Then I need to make sure my lighting power that runs through the track, still reaches all the buildings!

It is supposed to be nice all next week except windy on Monday so I should be able to get the Right switch placed and then even out the spacing on all the joints from Indian Hill Bridge to the mainline connection to the right switch.