Here are some links to images and animations of valve gear found via searching Google images for steam locomotive valve motion. Going to give references for both inside and outside motion. http://www.steamlocomotive.com/appliances/valvegear.php

____________-

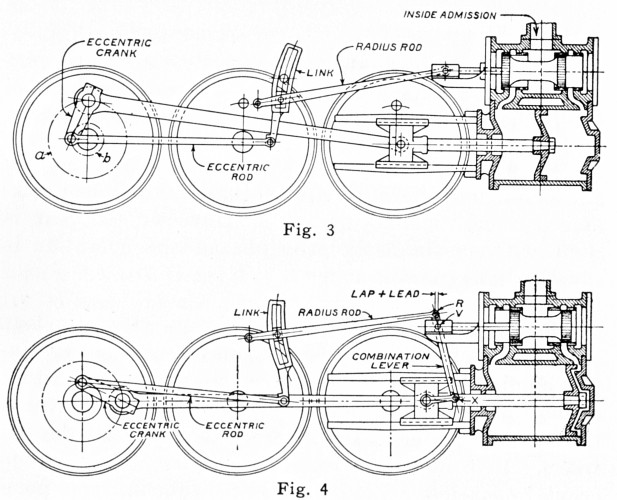

From http://www.cwrr.com/Lounge/Reference/baldwin/part01.html 21. Walschaerts valve gear is used, with an inde-pendent motion for each cylinder, but all controlled by one type B Ragonnet power reverse gear. The valve for the left-hand cylinder is operated from the left-hand main pin and crosshead in the usual way. The right-hand valve receives its lead from the right-hand cross-head, but the link for this cylinder is operated through a transverse shaft, by means of a connection to the left-hand crosshead. The return crank on the right-hand main pin is set to operate the valve for the inside cylinder, and this valve is given lead through a connection with the inside crosshead. The arrangement of the links, arms and rockers through which these connections are made, is shown in the accompanying drawings. The valve motion bearer is a single steel casting supporting practically the entire valve gear. Plan View of Valve Motion Side Elevation of Valve Motion __________–