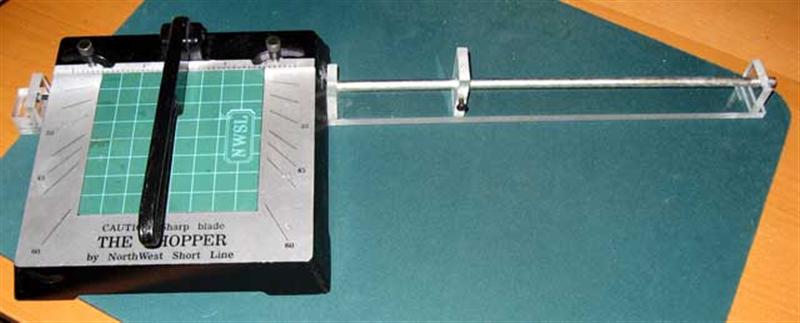

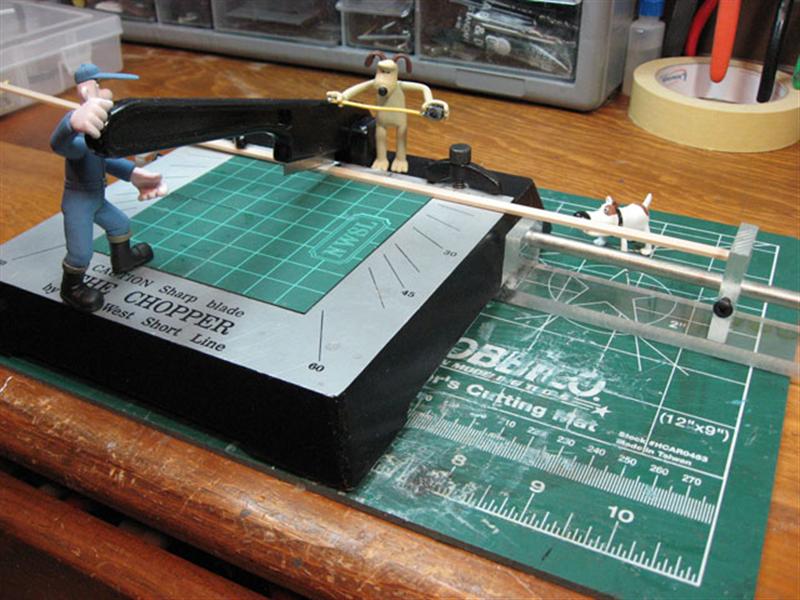

The Chopper II from NWSL is a neat tool…for HO. Hehe…well, it’s also nice for large scale, but if you have to cut pieces over 2 1/2" long, you’re out of luck. A couple of years ago, Jack Thompson had posted a design on some other board to extend this. I had vowed to build something similar, but it remained one of my many unfulfilled ideas until tonight. I’ve been building my boxcars and had tired of cutting 5 inch pieces. I looked around the workroom. Hmm…an extra piece of acrylic from my current building project, and a bar left over from my turntable. I’m set. A couple of swipes on the table saw, some drilling, then tapping, and voila! I can now cut longer pieces!