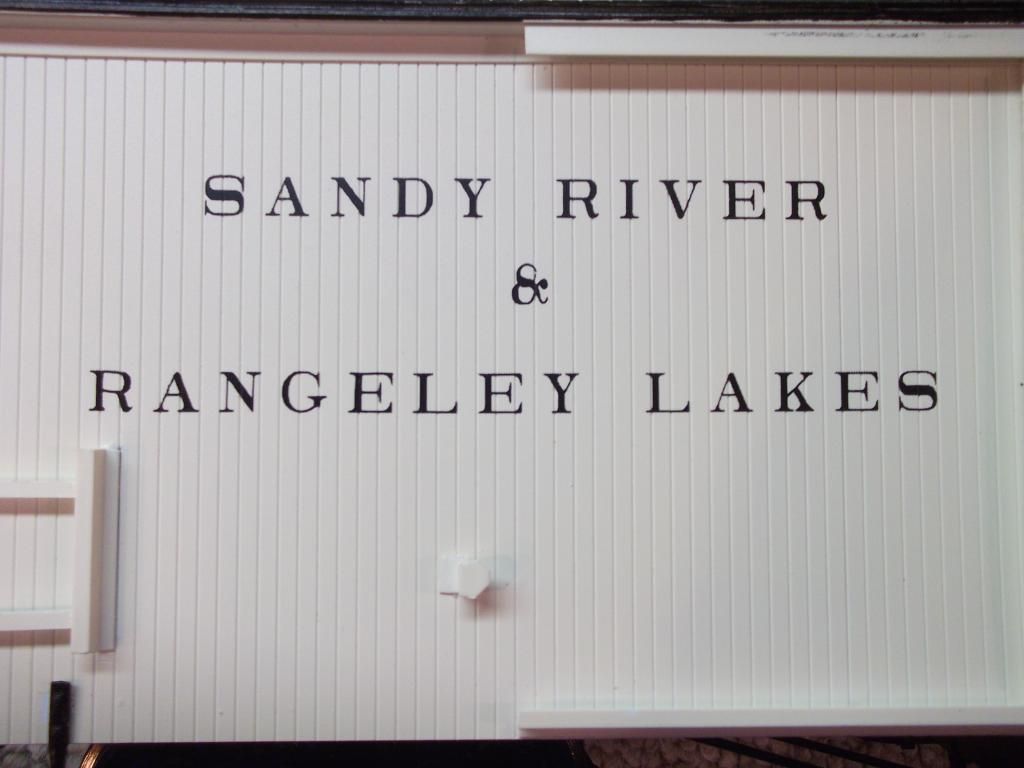

Finally got around to lettering some recent projects. Got me to thinking why I chose Dry Transfers over decals and wondered what others thought. A quick review of the pro’s/con’s… Here is a sheet of custom transfers…Cost me $80.00 ($28 for the plate, $24 for computer time, $25 per printed sheet). Likely a “CON” but honestly custom cut vinyl will be similar, no idea as to equivalent decals. . .

. . CON…Placement/burnishing is not as easy as you might think. The sheet “stretches” and care must be taken for it not to slip or stretch when applying. You need to leave sufficient space around the image for handling (no butting up text). Taping into place helps a lot! . . Big burnisher for large work…And a small tip for tight spaces/small lettering. . .

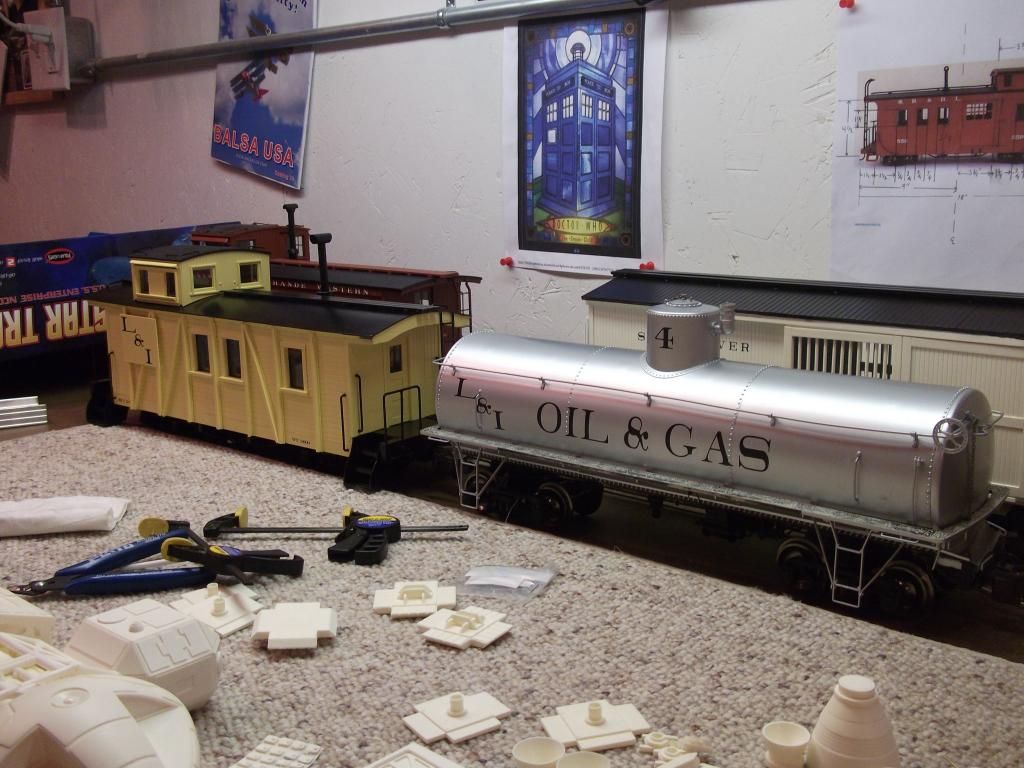

. . PRO…When you’re done you’re DONE! No need to over-coat and no evidence of a ‘backer sheet’ because there is no backer! . .

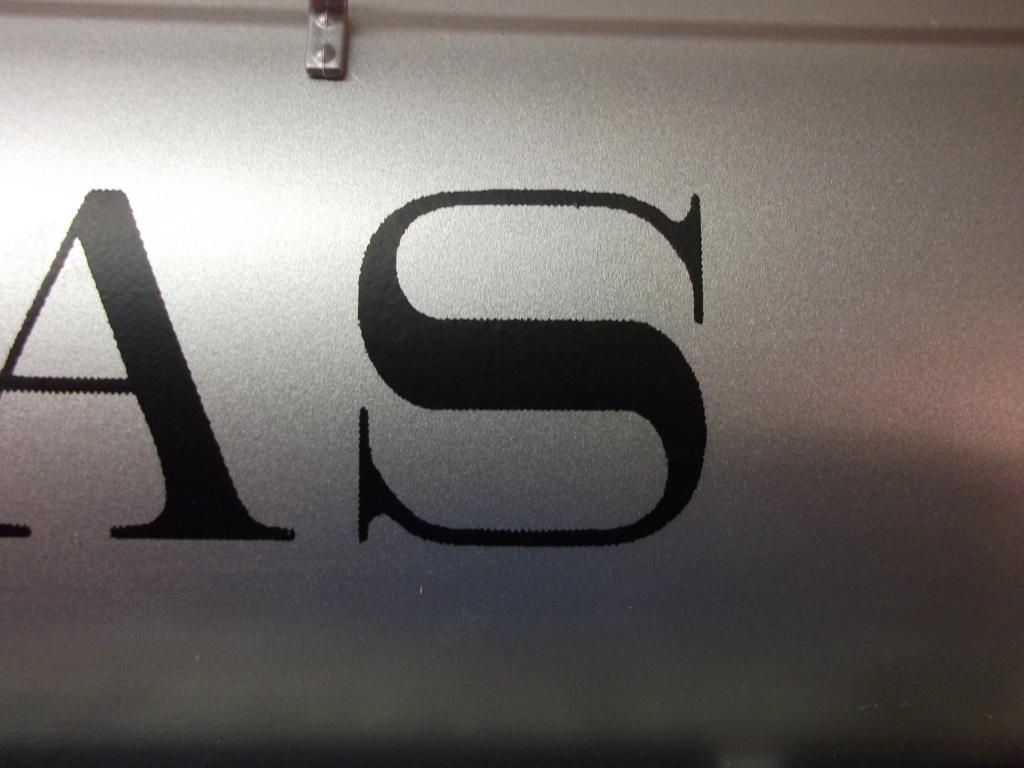

. . CON…You get what you get. You give them a file with poor resolution, you get poor resolution back. . .

. . All in all I am happy with the efforts. $80 = 4 cars…$20.00/car. . .

I also measure a letter height and supply that with the order. Assures you will get what you wanted.

I also measure a letter height and supply that with the order. Assures you will get what you wanted.