John, I looked into centrifugal pumps being advertised in the western US for windmill use in the 1870-1880 time frame, but the only cases I saw were in Australia. Very interesting though, and thanks again for bringing up that possibility.

After checking on the timing & circumstances, I have to conclude that it was probably Southwick’s pump that was originally installed at Mound House. Southwick claimed, in his 1870 catalog, that his mills were supplied with a free pump & pipes, and from 1875 onward he displayed his pump along with his mill at annual trade shows (e.g., in Sacramento). Since it was in 1876 that the Mound House mill was sold and erected, a free Southwick pump would have been included, and likely installed.

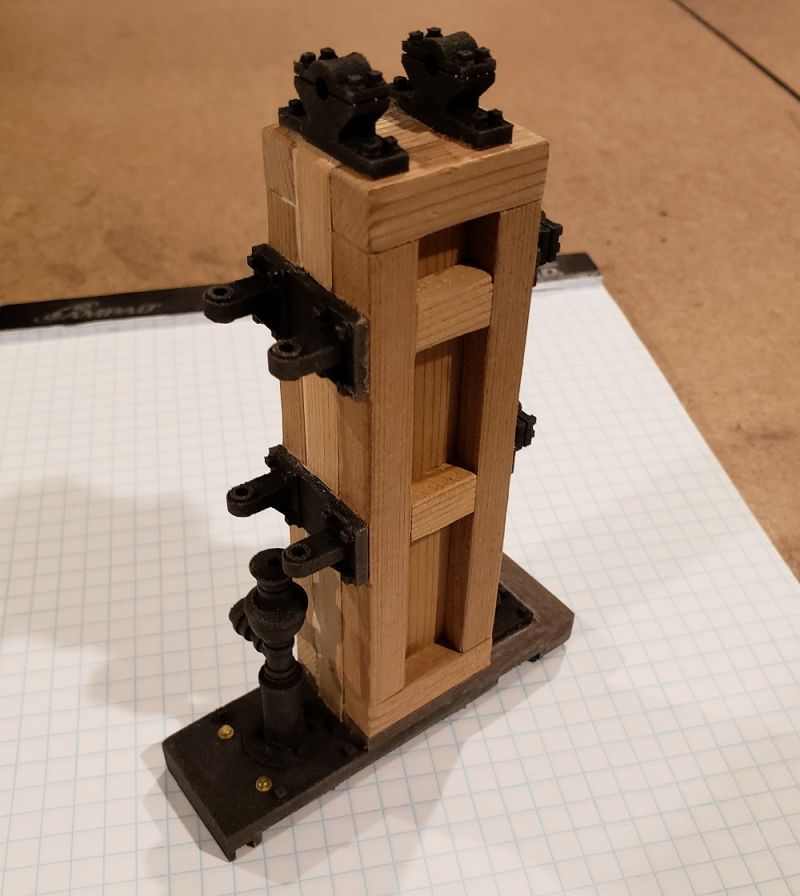

I don’t know how it was connected, so I have had to imagine some contraption. Since I’ve seen a vertical crosshead applied for a different vertical-axis mill, I’ve gone in that direction here.

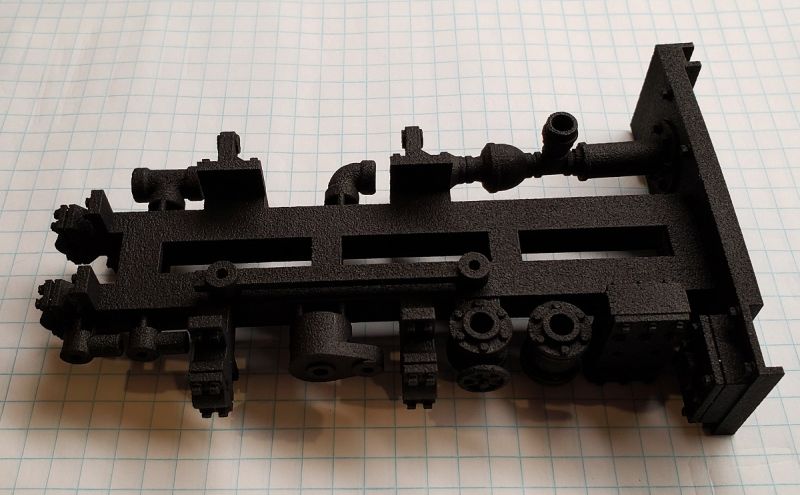

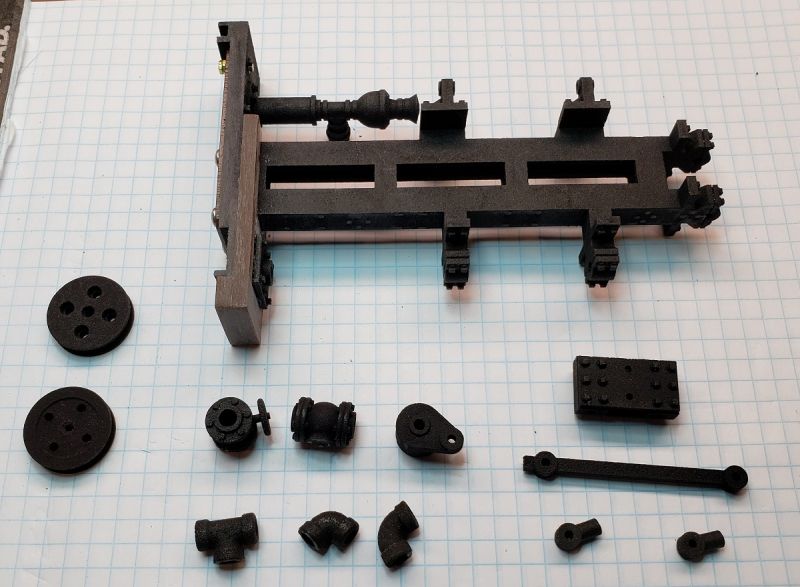

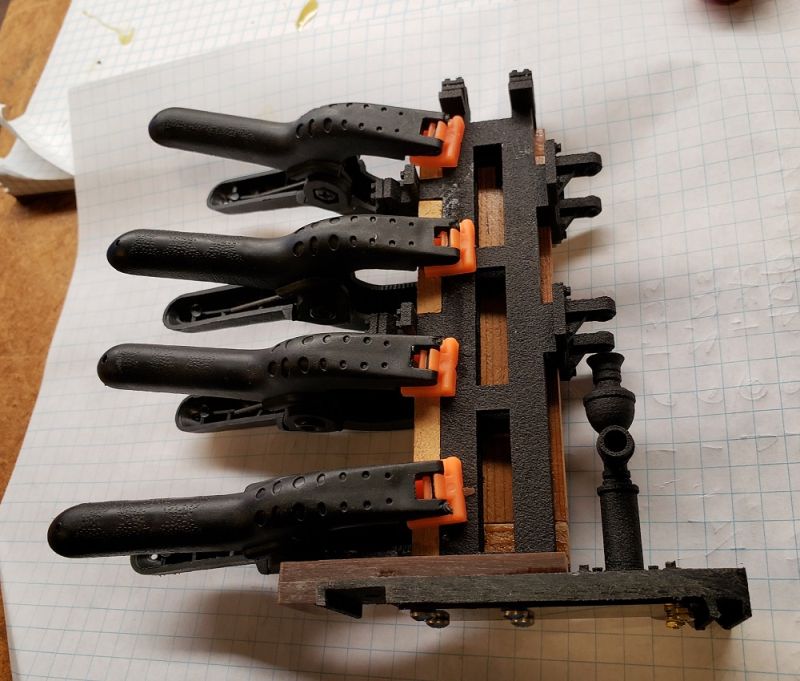

To simplify construction and ensure alignment, a single 3d-printed core (shown in dark gray) holds all together. Brass shafts connect the moving bits, and cedar forms the cosmetic frame.

Here’s a very rough video (I couldn’t get Solidworks to cooperate on this), which you can loop by right-clicking in the middle of the video and checking ‘loop’.

Not quite done with all this, but I wanted to give an update.