Devon Sinsley said:

Cliff that is just so cool. Now you made the comment that the turbine is heavy and takes time to get to speed. I wonder how the weight of your model compares to the weight of the real thing. Does it scale out heavier or lighter do you think?

No I want to see it pump water. Make a working pump and you might catch my attention. . .yeah right. simply cool my friend.

Thanks Devon, and I’m glad you like it. Dave Meashey and Jim gave great replies on the scaling of mass and force, and I sure can’t top those.

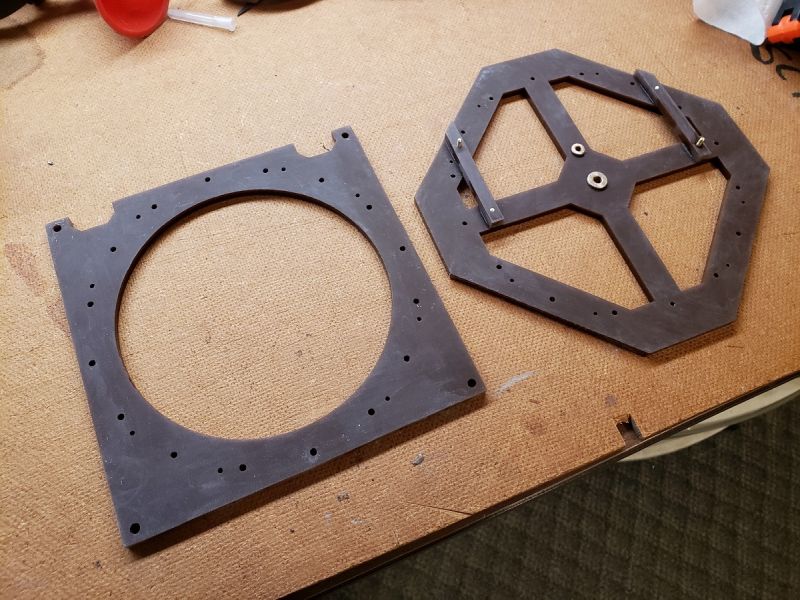

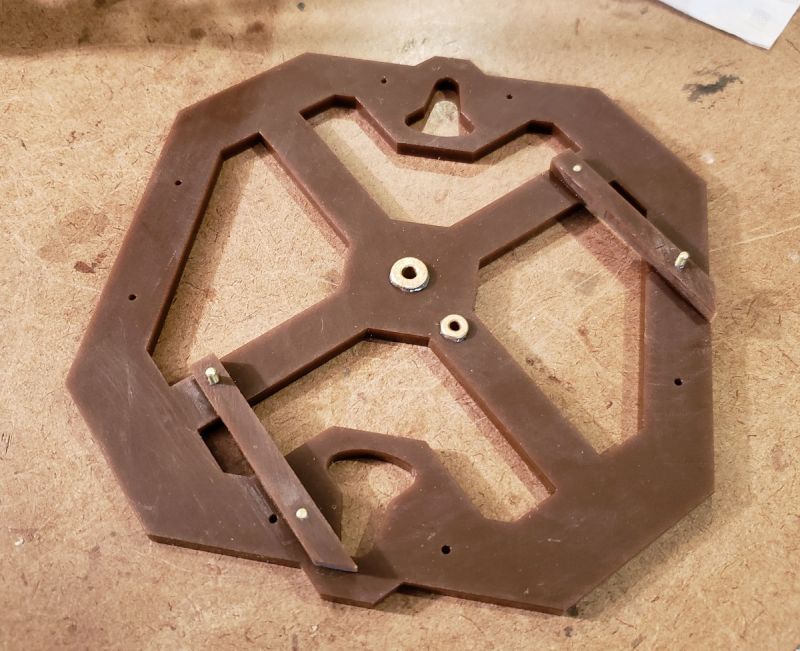

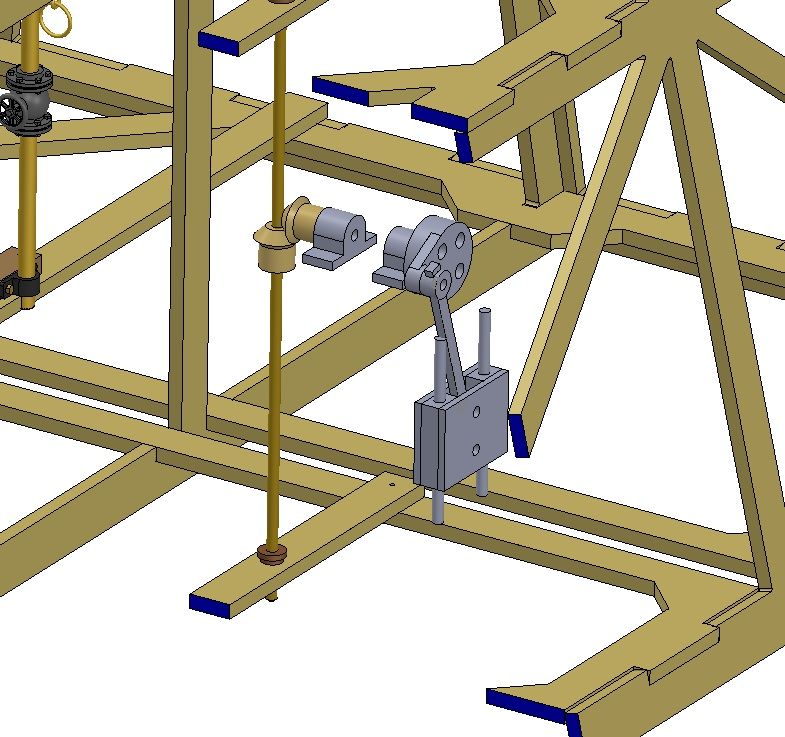

As for pumping, yeah, I get it that you and Dan would like to see that… thanks for the encouragement… We’ll see. My big objectives now are to get the vertical pump drive shaft going, and the remaining painting / weathering / clear coating done.

Beyond that, I’d like to do a simple mechanism convert the vertical rotation to vertical reciprocal, with a rod going down and disappearing probably. That’s because the pump would have probably been installed below the frost line, according to one source. Still working all that through.

If anyone’s seen a mechanism like that, please send me a link. The only one I’ve seen was way complicated. The most straightforward approach I think would be to do a miter gear pair, with the new horizontal shaft driving a wheel and drive arm, the opposite of a steam loco’s cylinders driving its drivers.

[edit]

After hunting around for miter gears, and not finding an affordable pair that meets the requirements, I’m realizing that any little mechanism like this will only last a few weeks. So, I’ll probably just let the vertical shaft go into an above-ground box, and saw that’s where the pump is, and call it a day.

But, I might put a motor in the box, and let it act as a generator. Not sure, haven’t worked it out.

Thanks for all your kind comments guys, and your participation with me in this project. Means a lot.

Cliff